Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

The 5 most common errors in kitchen design

The 5 most common kitchen design mistakes and how to eliminate them quickly – read more.

A properly designed kitchen makes day-to-day life easy and allows for maximum use of space. Creative solutions and well-thought design additionally boost its functionality and aesthetic values. The current market offers many design offerings, design software and modules, as well as interior design inspiration. To make sure you don’t get lost in the plethora of information and advice, we have prepared basic guidelines that describe the 5 most common kitchen design mistakes, as well as how to solve them quickly.

1. INCORRECT PROPORTIONS

Incorrect proportions hinder movement in the kitchen and distort visual reception of the room, e.g. too large or too small island relative to the remaining cabinetry, insufficient number of wall-hung cabinets in relation to wall surface, highly variable size of white goods and other interior furnishings. Let’s see which of WOODEXPERT’s functionalities will allow you to check and avoid these mistakes.

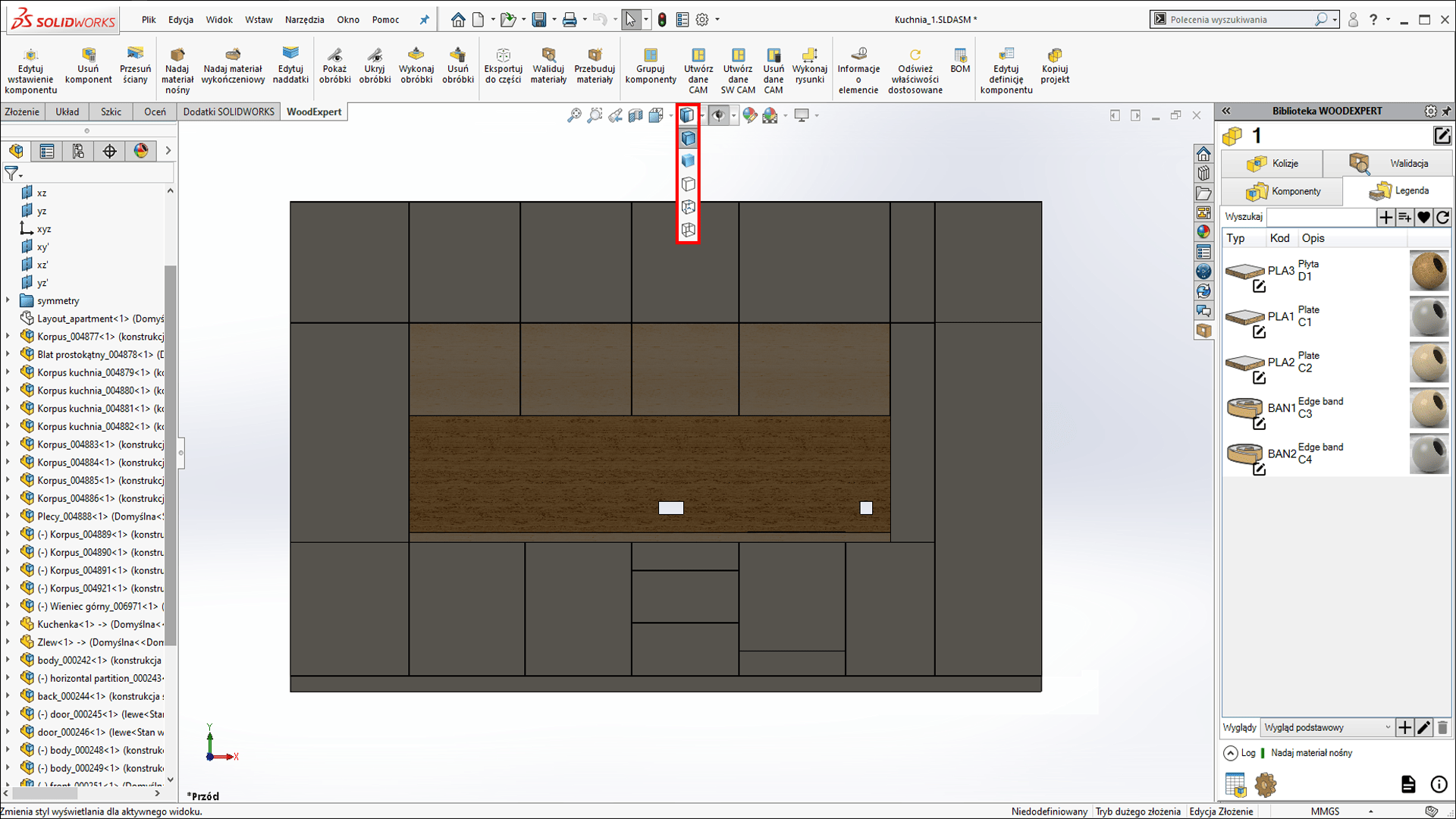

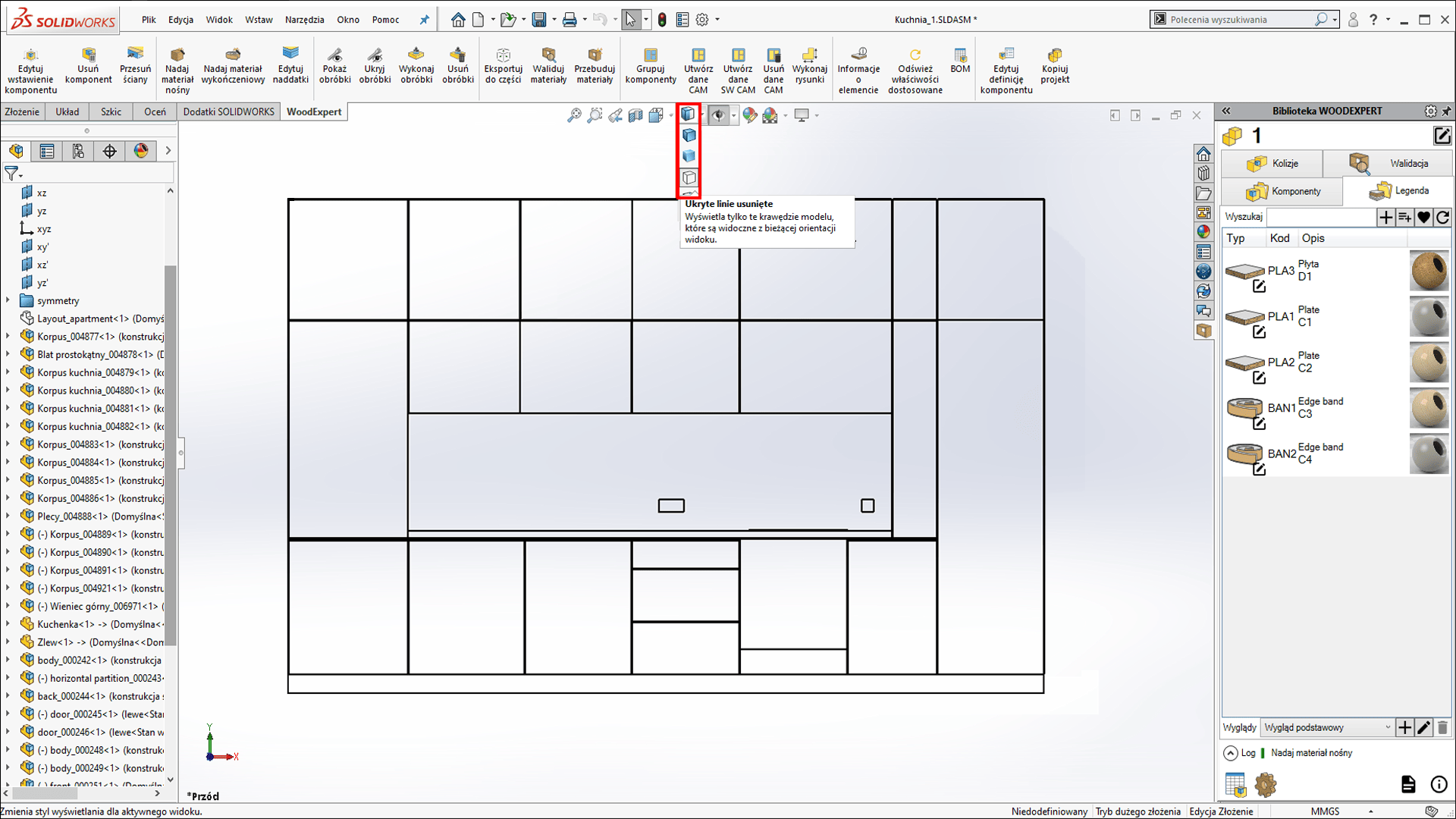

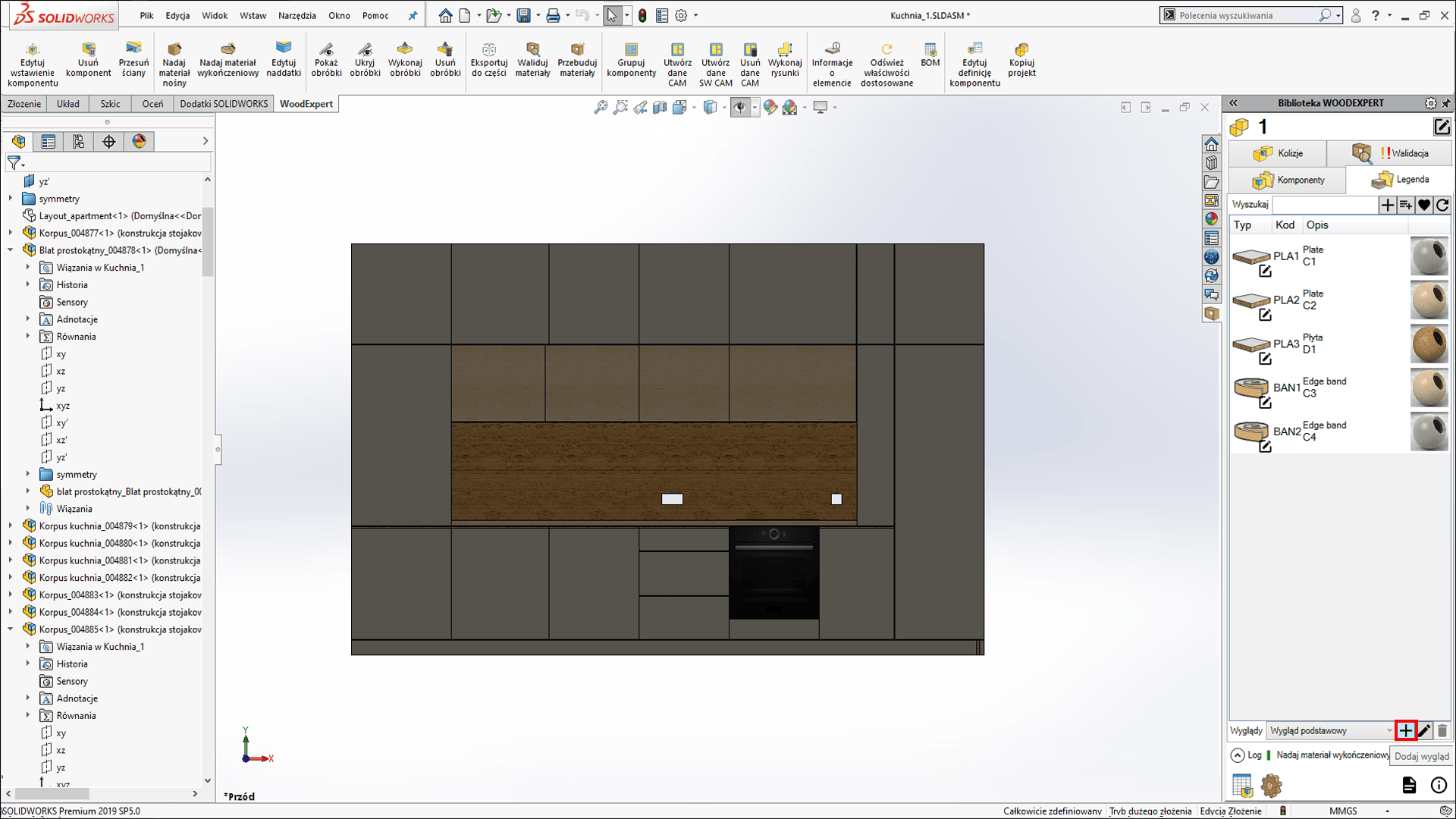

These two important WOODEXPERT functions are continuously available while working on a model. “View orientation” allows you to observe the kitchen model in six basic views, isometrics, and display from one to four windows with the views of your choice simultaneously. This allows you to simultaneously observe the kitchen in different contexts and evaluate its proportions and layout in a given position. “Display styles” are used to control edge overlapping and layout of interiors of all cabinets in a given view.

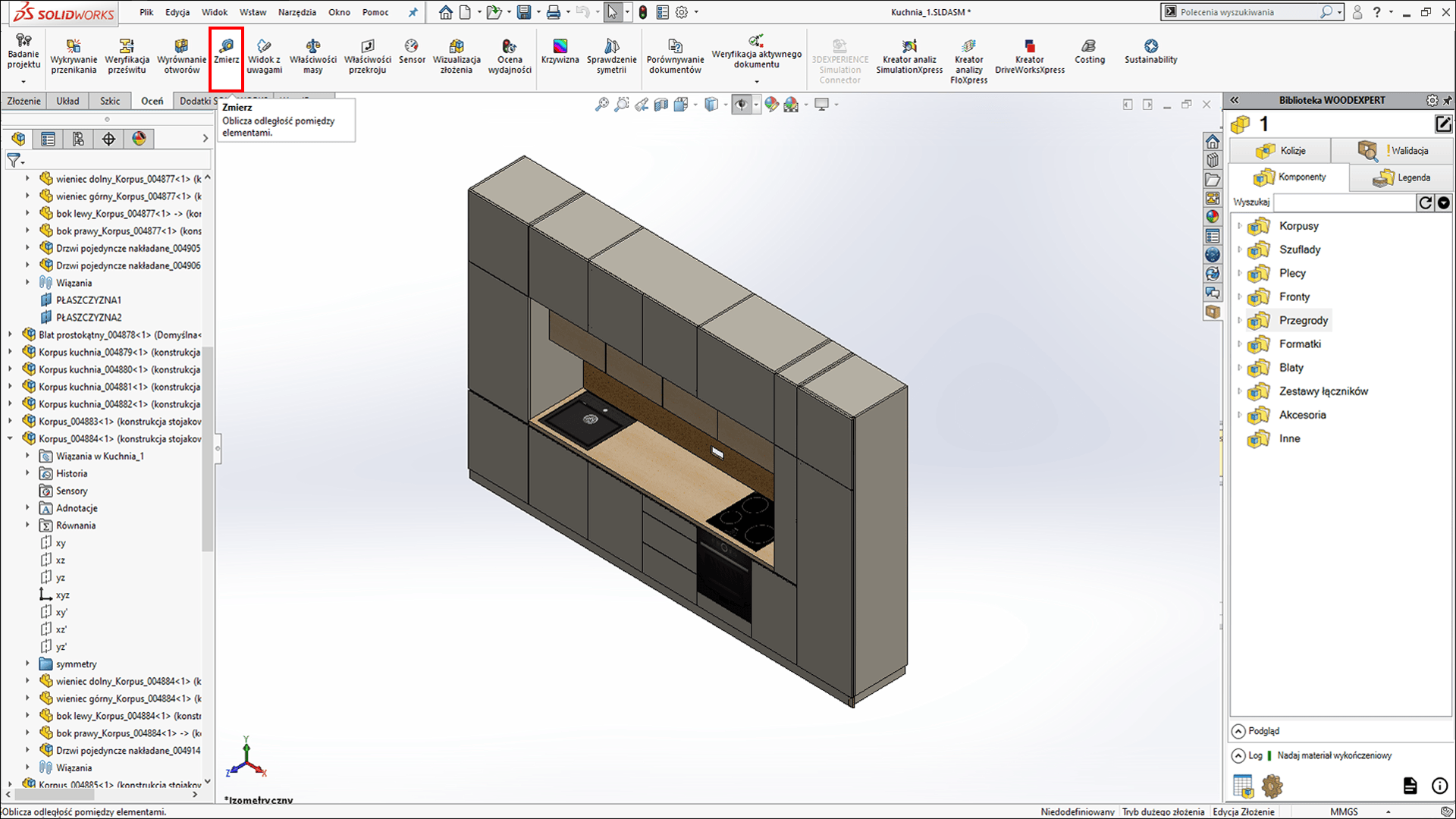

With the “Measure” function we can quickly and accurately evaluate specific distances within a model. This allows you to constantly control the layout of the kitchen and change and maintain all the proportions.

2. INCORRECT DOCUMENTATION

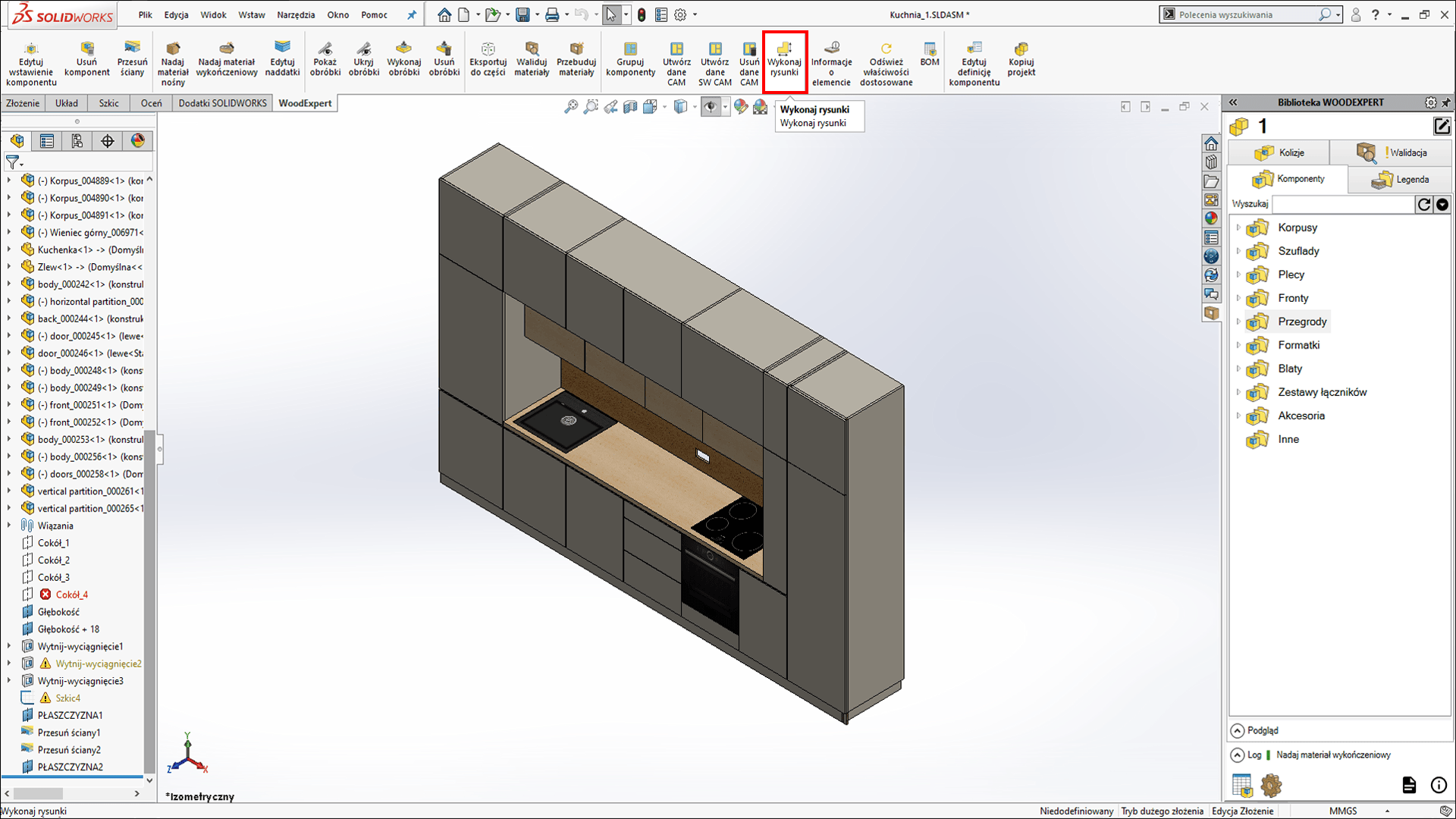

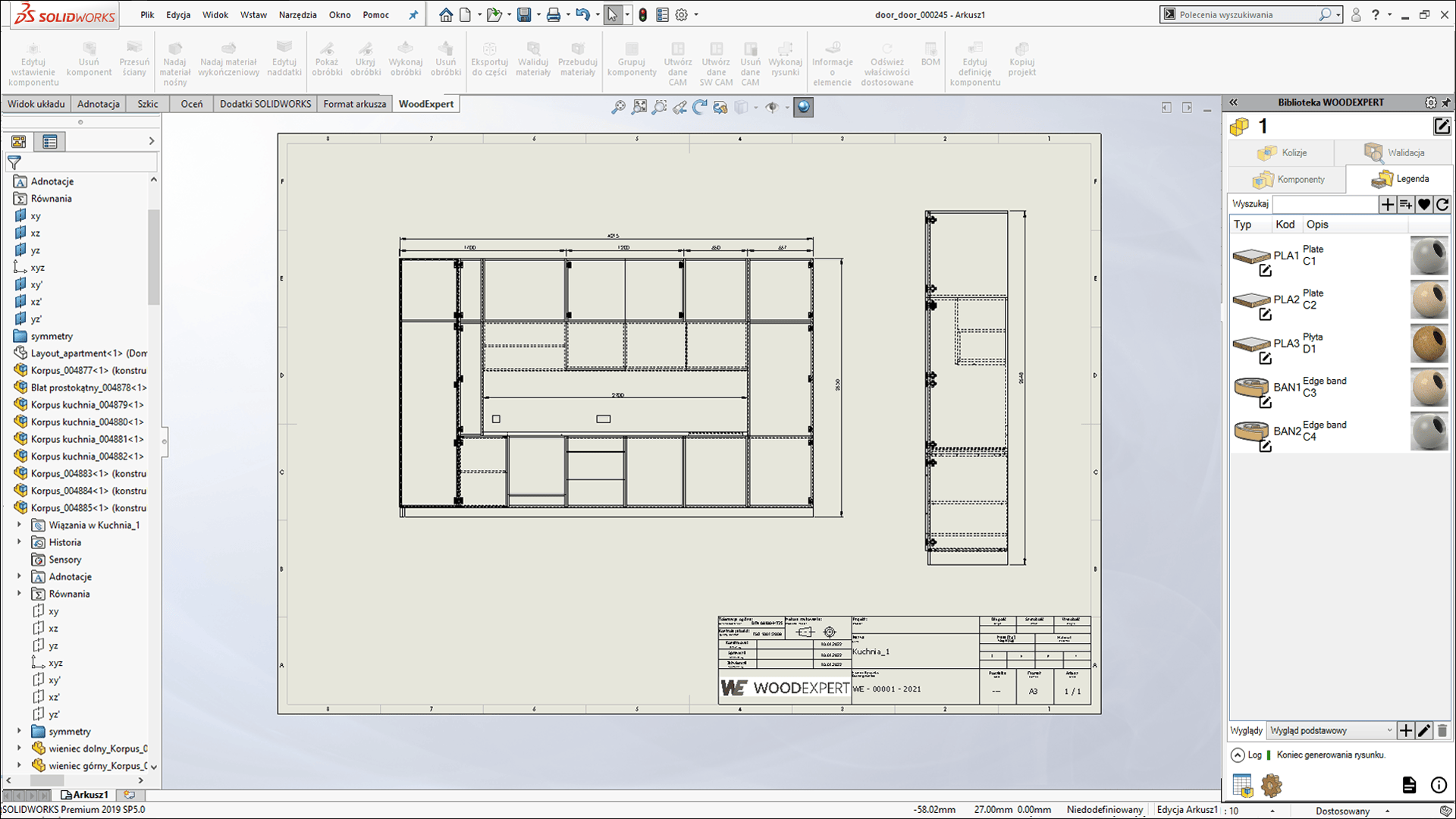

Apart from additional effort, time and costs, developing technical drawings manually in other software entails high risk of dimensional errors. Even a single mistake results in irregularities carrying great risks when making customized furniture. In WOODEXPERT, drawings are generated with a single button in a unified working environment.

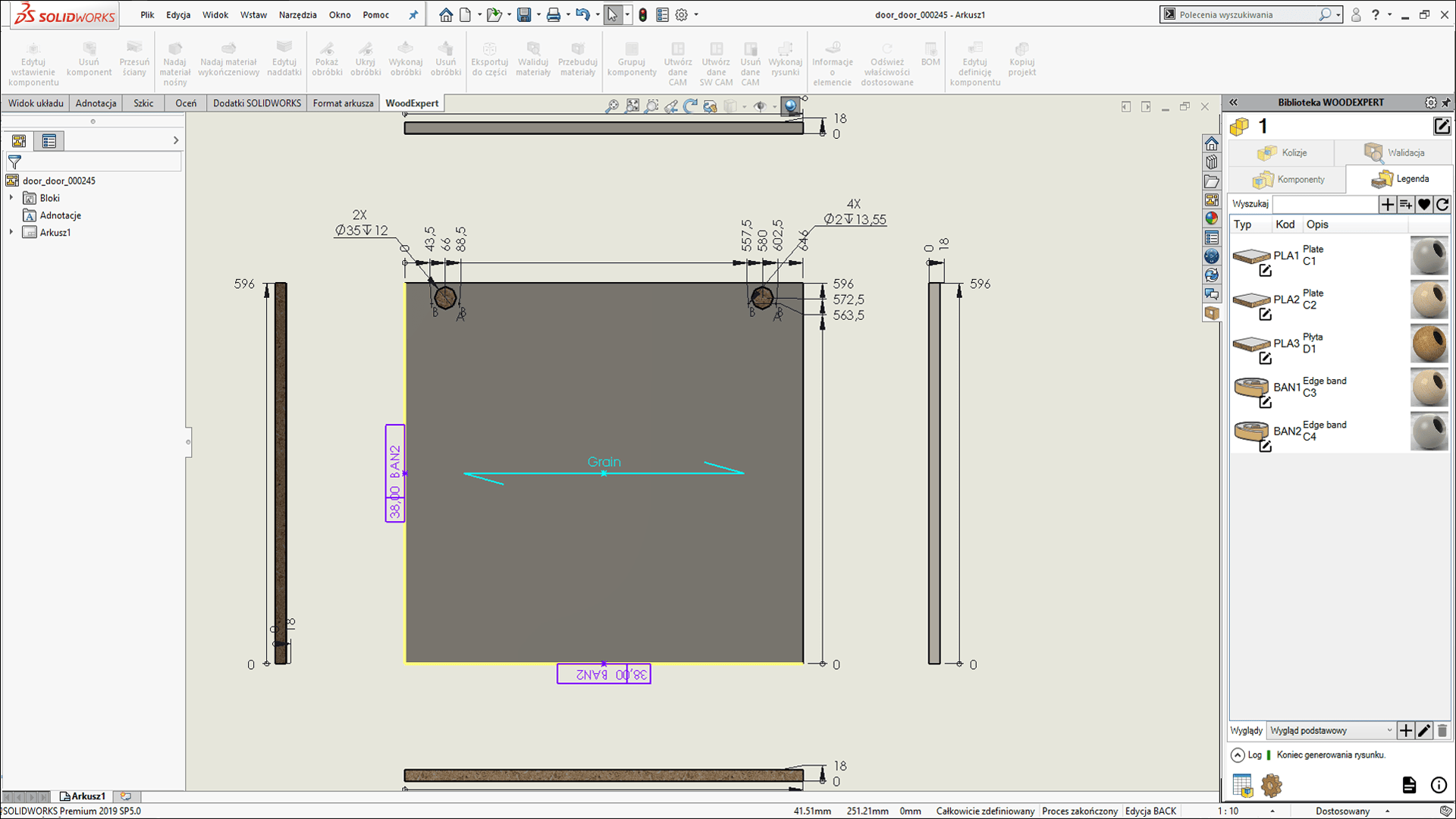

Based on the model, you get automatically generated and dimensioned drawings with the data necessary for production in seconds. As you can see, one view includes accurately dimensioned openings, all edges, details on edgings and natural wood grain.

Extensive capabilities of drawing sheet configuration in WOODEXPERT, and the possibility to set style, scale and position of a view on an individual basis give you complete control of accuracy in a design within a single environment and in a short time.

3. INCORRECT LAYOUT OF SHELVES AND FRONT OPENING SIDES

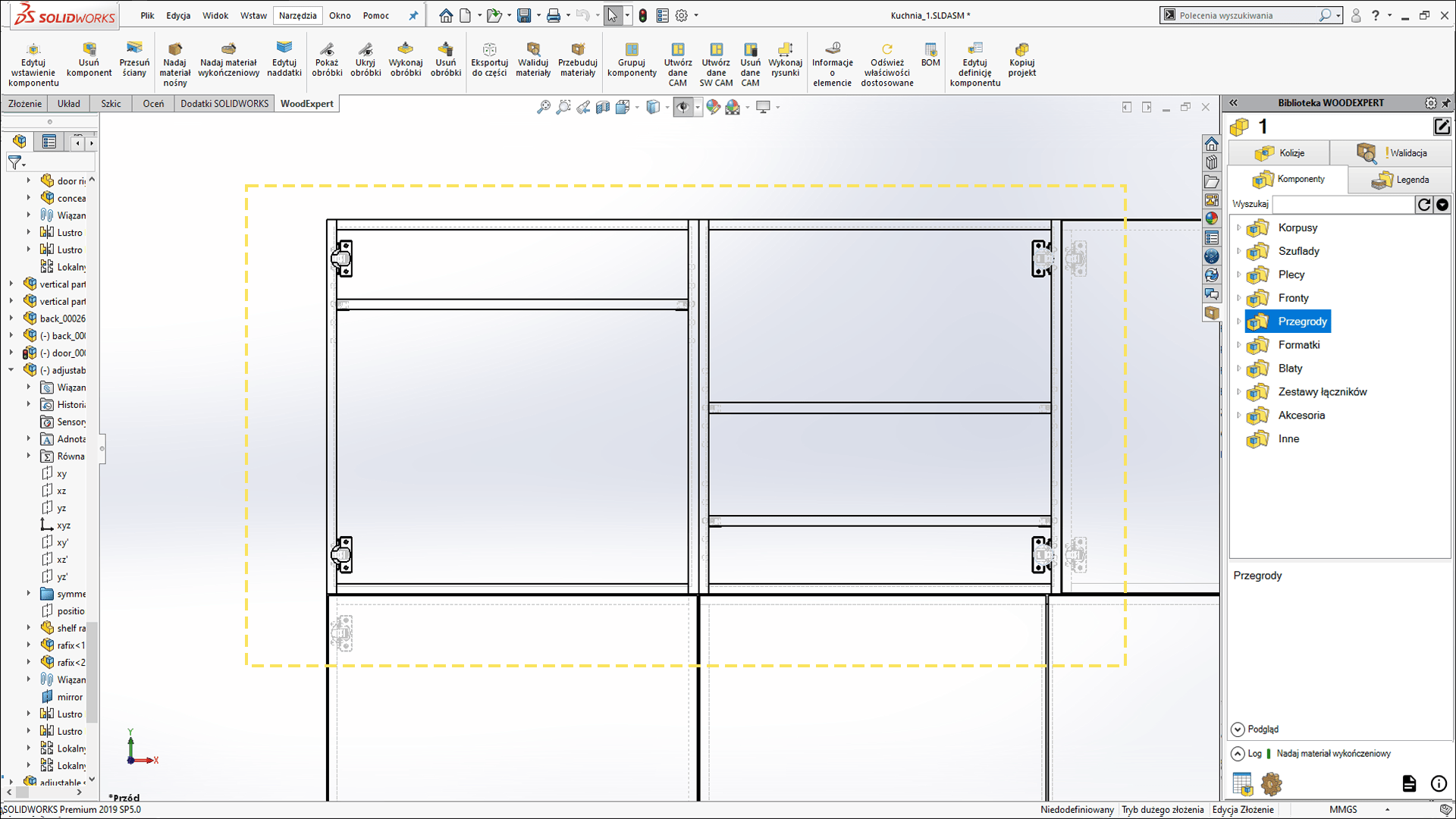

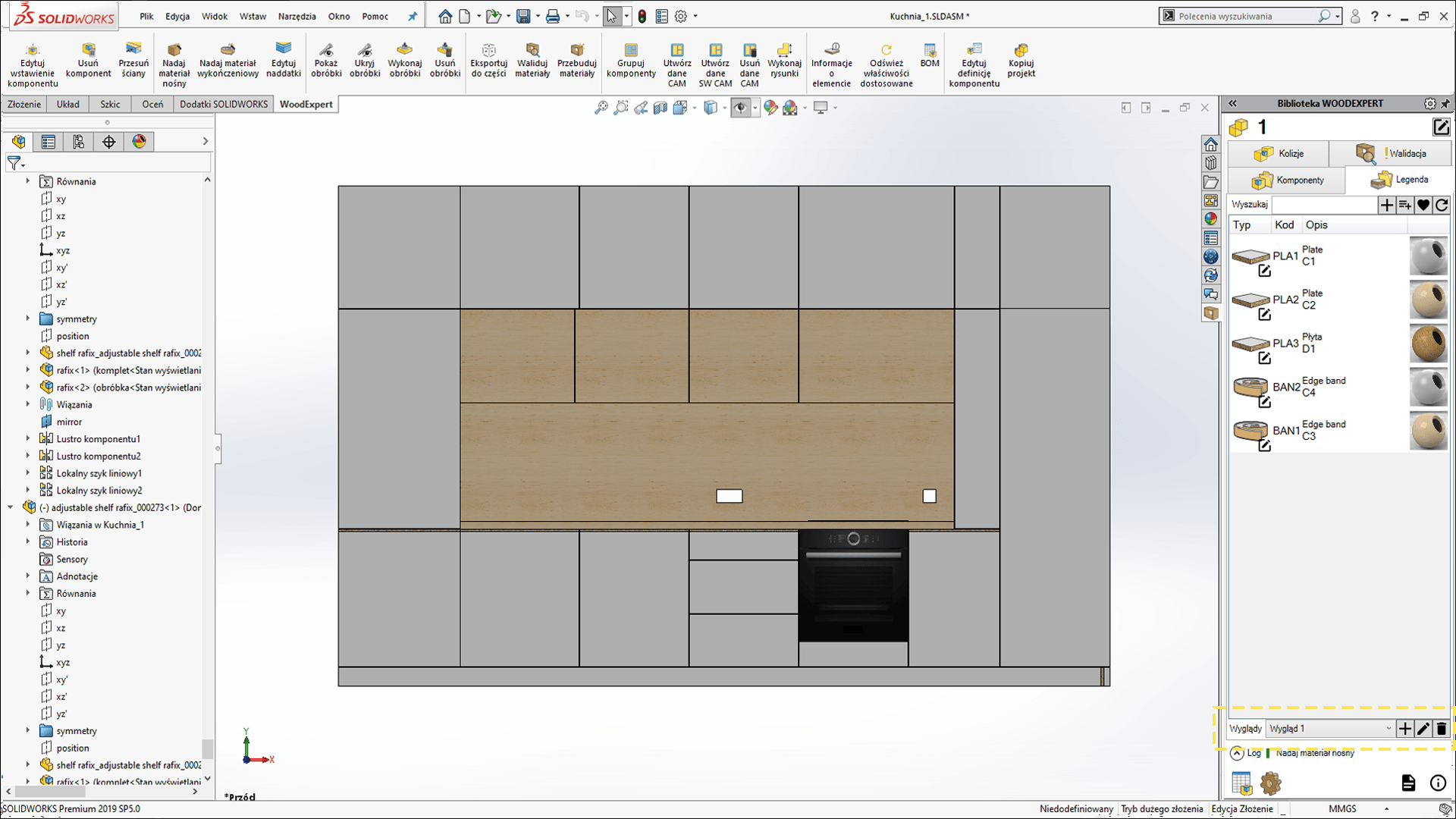

This is the most often overlooked issue in kitchen designs. The body layout alone is not enough to ensure ergonomics in the room layout. The number of shelves determines comfort and movement in a kitchen. Properly selected panel distances, quantities and positions make it possible to create a well-arranged layout, store equipment with various overall dimensions according to the frequency of use, and positioning of white goods in proper order and at proper height. Let’s see how to improve their mutual arrangement without removing any components.

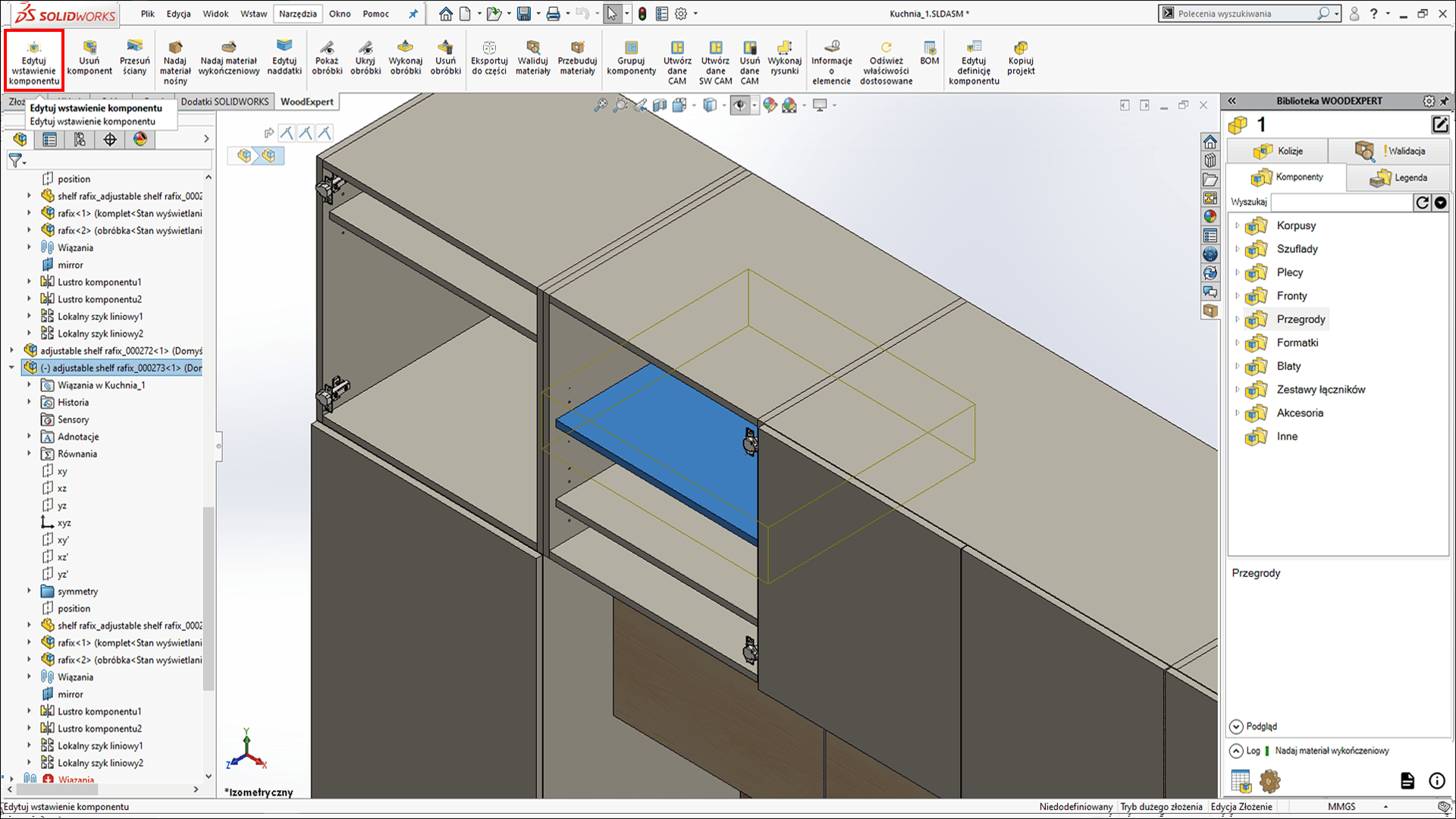

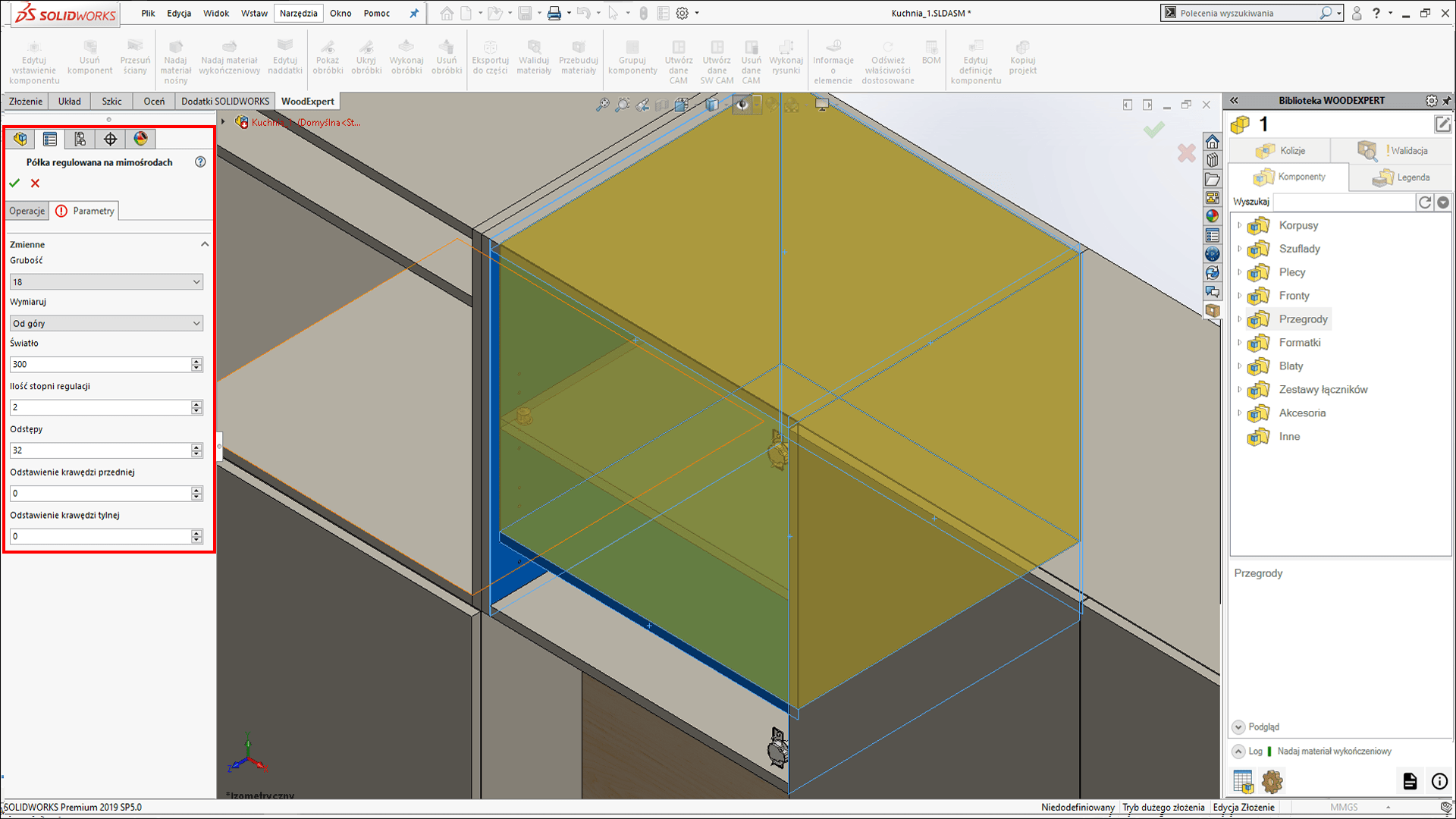

With the “Edit component insertion” function you can adjust all panel parameters. The most important ones to adjust under the “Parameters” tab include:

- panel-to-panel clearance;

- front edge projection;

- panel thickness.

In the operations window, you can create panel references relative to each other by quickly specifying height and width parameters, pointing to specific bottom and top planes.

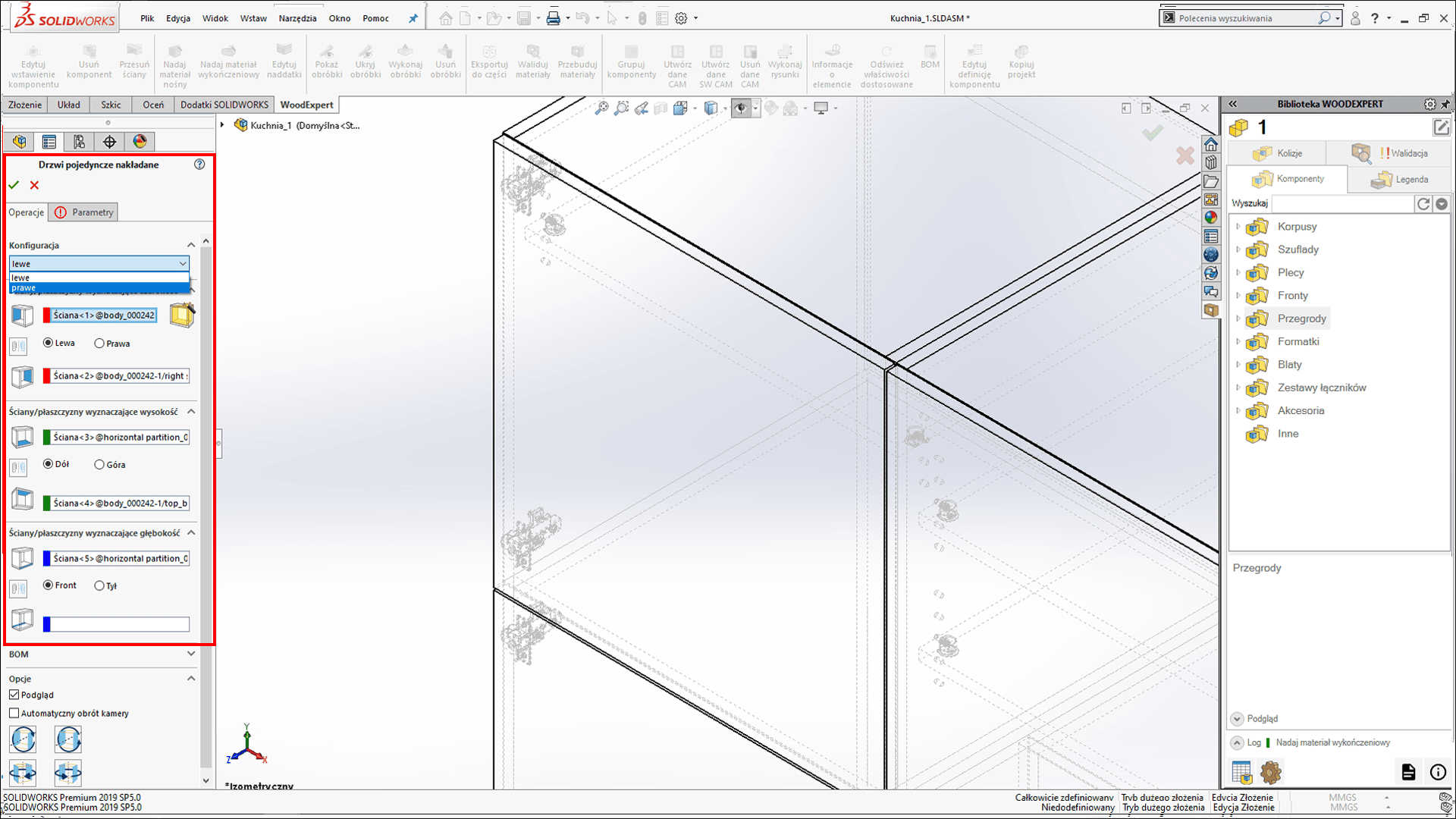

Door parameters can be adjusted in the same manner. With the “Edit component insertion” function, you can at any time change the following:

- door opening side;

- edge projection;

- panel dimensions and more.

4. INCORRECT COUNTERTOP HEIGHT

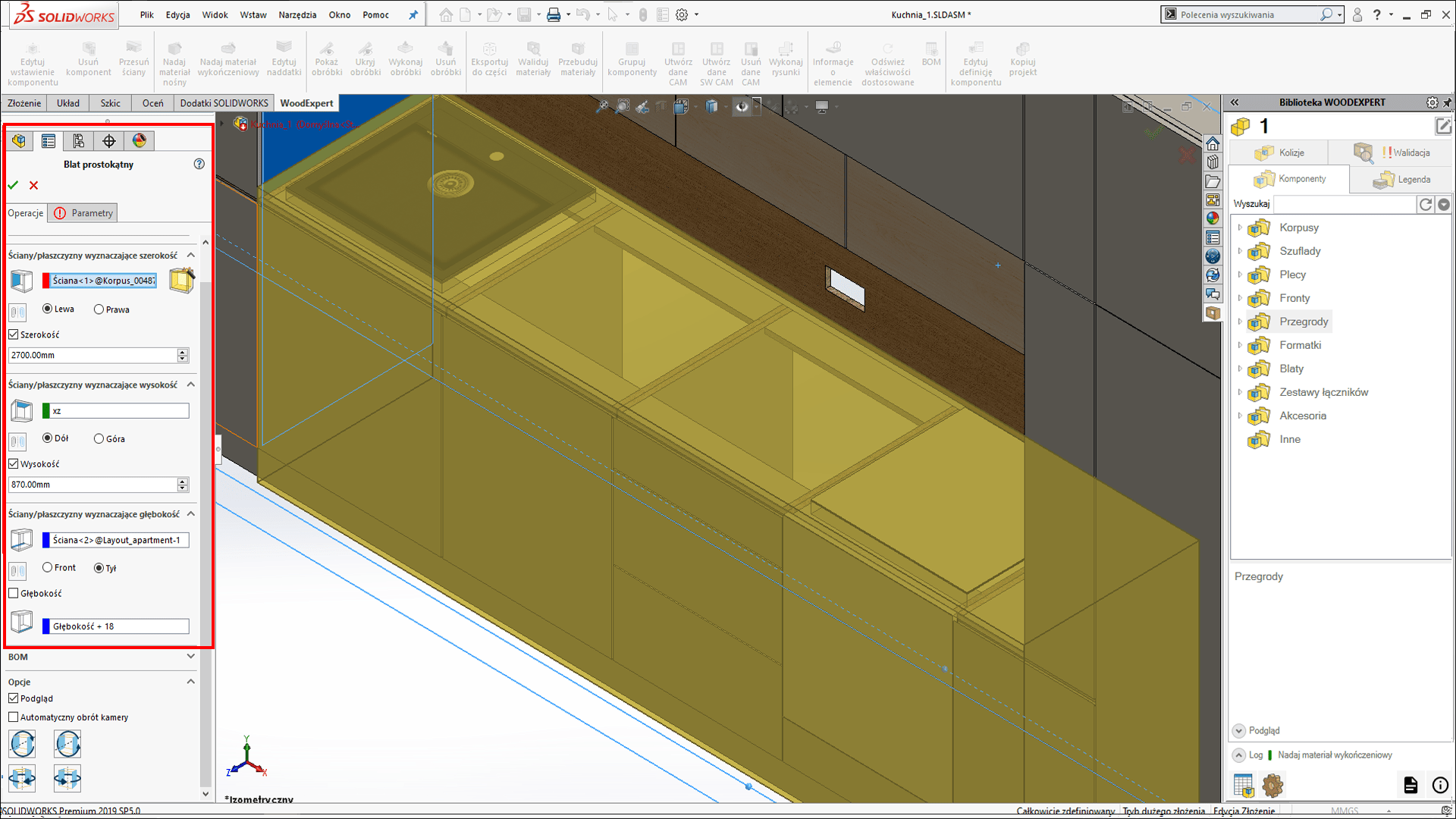

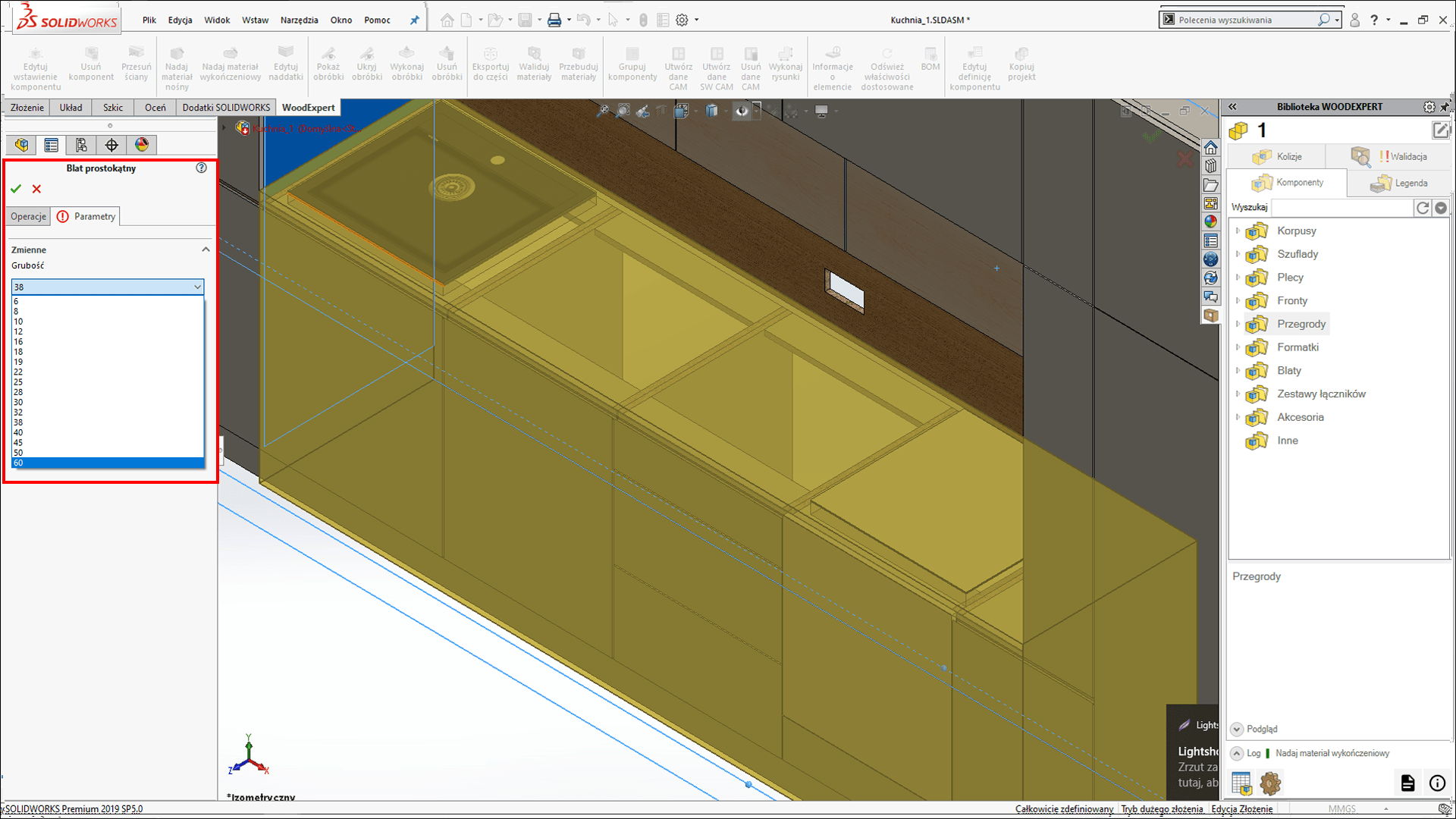

Incorrect height of the countertop is a common mistake during design, due to forgetting about the height of the legs and pedestal. Also, the thickness of the countertop is much greater than a standard slab. This value is 30–60 mm. The countertop height is checked in WOODEXPERT in several places. Apart from direct dimensioning in the documentation, this value is seen immediately upon selecting a component.

The countertop height can be specified freely and selected from the variables under the “Parameters” tab.

5. CHECKING THE DESIGN IN ONE COLOUR OPTION ONLY

Often we stick to the first and only idea when choosing colors. With the “Variants” option in WOODEXPERT, you can create several colour variants to specify the character of each panel in a given look. This allow you to:

- visually compare various kitchen colour options;

- check price difference of given options: WOODEXPERT automatically differentiates and valuates looks;

- avoid improper decision without prior comparison of costs and designs.

Errors are inherent when working on a design. It is important, however, to verify them quickly and resolve them without incurring costs at the design stage. With its functionalities, WOODEXPERT is a perfect tool for such purposes. You can find out for yourself by testing the software for 30 days for free. Write to us!

If you’d like to get more tips, check out our “Good Design Practices” series.

Author: Ewa Gaczorek, WOODEXPERT specialist

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…