Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

12 TOP tips for WOODEXPERT users

We present 12 TOP tips for users of WOODEXPERT, the intuitive 3D CAD software for furniture design and production.

At the beginning of your design journey in WOODEXPERT, you usually start working with a baggage of experience and habits taken from other 2D and 3D softwares. In the daily routine and specifics of our work, we often do not have time to test new solutions and search for further functionalities. WOODEXPERT, as a comprehensive tool for the design and production of furniture, offers many functionalities that can be combined to create new, innovative solutions. The integration of WOODEXPERT with SOLIDWORKS further extends these possibilities and allows them to be tailored perfectly to our individual needs. I have prepared 12 TOP tips for WOODEXPERT users that will enable you to work pleasantly and efficiently:

1. By subscribing to WOODEXPERT you can create your own functionalities

One of the key advantages of having a WOODEXPERT subscription is that you can benefit from the technical support of dedicated furniture specialists. Through the issues you report most frequently, we identify your needs. In the ticket panel, you can also enter your suggestions for the desired functionalities. We consider every suggestion you make – this has resulted in, among other things, the “Project TAG” function and thus the possibility of giving your own names to assemblies and parts.

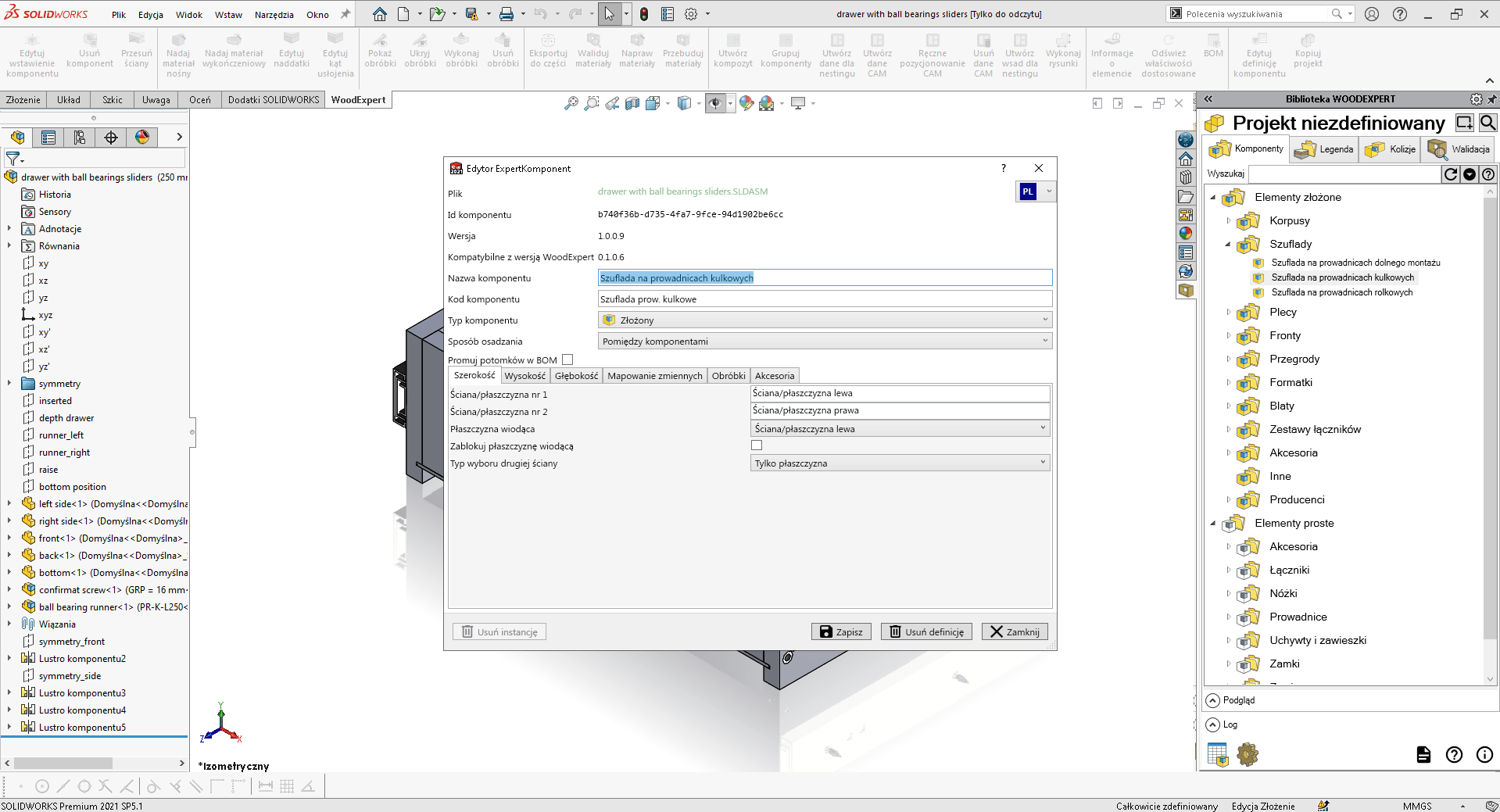

2. Rename default library components

The default library of WOODEXPERT can be freely optimised and renamed according to your preferences and company specifications. In addition to being able to add complex and simple components to the WOODEXPERT library, you can rename existing library components at will. Simply open the selected component from the library and then select the “Edit component definition” option. Here are the next steps of the operation:

- renaming to the preferred name in the component name line

- saving the assembly

- closing the assembly

- refreshing the library.

This makes the default form of the library perfectly suited to your needs and the nature of your work.

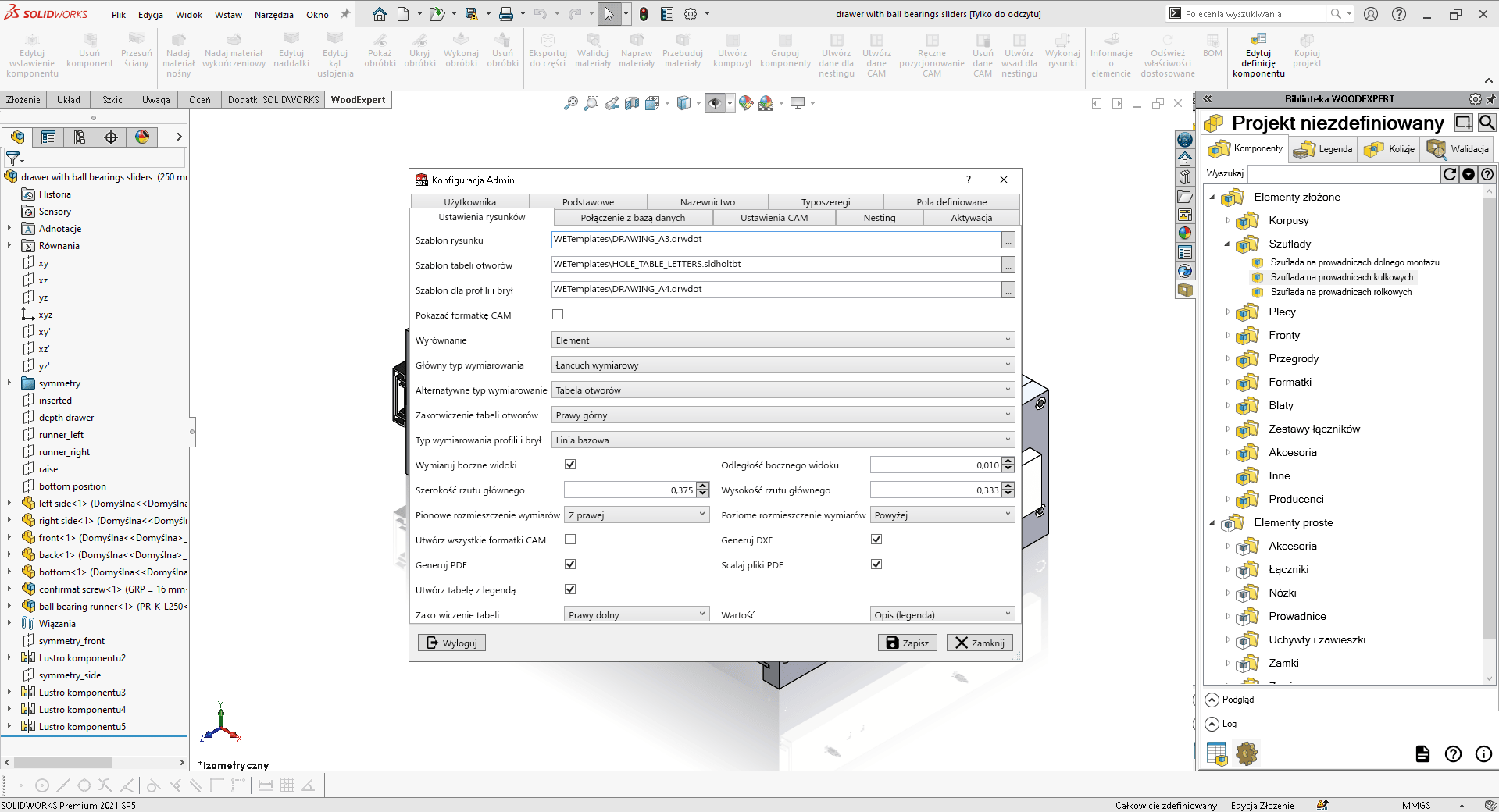

3. Start generating automatic DXF and PDF files

The ability to automatically acquire drawings in PDF and DXF form further streamlines the process of creating the necessary design and manufacturing documentation. This option is available from the user settings in the ‘Drawing Settings’ tab. This provides you with ready-to-use files straight away, without having to export them separately.

4. Expand your drawings with the views palette

The views palette is a great starting point for creating furniture assembly instructions and advanced 2D drawings in a rapid manner. By selecting an assembly or part and dragging and dropping it onto the drawing sheet, plus annotations, you can create individual instructions for a selected piece of furniture or a detailed description of a model detail for a customer or production worker in seconds.

5. One BOM, dozens of possibilities: create your own material lists

Within a single material list, you have countless possibilities for modifying and filtering the data. Often, out of habit, we generate another bill of materials or look into a model or stockroom to check specific information. It is worth reminding ourselves that, within the BOM, we can, among other things:

- create component groups

- edit gross and net dimensions of materials and components

- search for and open archived material lists

- create your own definable fields.

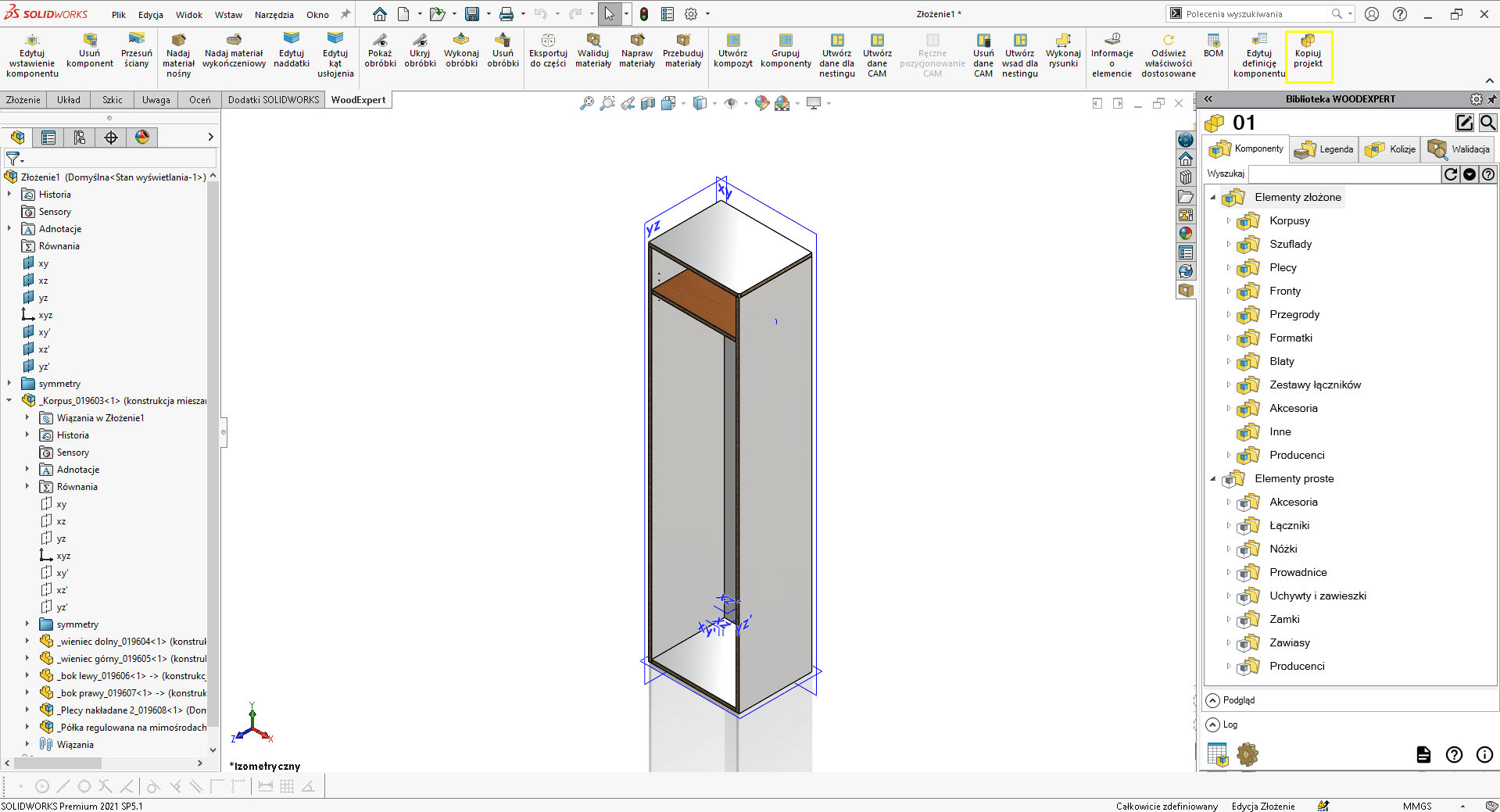

6. Don’t forget to copy projects

The project copy function allows you to quickly duplicate an assembly without having to re-create it. Importantly: the copied project has its own individual reference, which does not create complications when working on it. This is particularly useful when working on similar projects for different clients or when working on a collection of furniture with minor design changes.

7. Take advantage of SOLIDWORKS integration

Full integration with SOLIDWORKS is first and foremost a huge design resource:

- sketch operations: create any shape and cut-outs in the furniture board

- welded construction module: create welded constructions and combine them with furniture constructions in WOODEXPERT

- equations: create changes to the dimensions of an entire piece of furniture in an intuitive and automatic way

- configurations: i.e. the possibility of presenting a piece of furniture in several dimensions within one model.

The above-mentioned functionalities make it possible to design any piece of furniture to size and to create any number of versions and modifications based on a single model. This applies to both the furniture models themselves and all components, e.g. connectors, boards or materials.

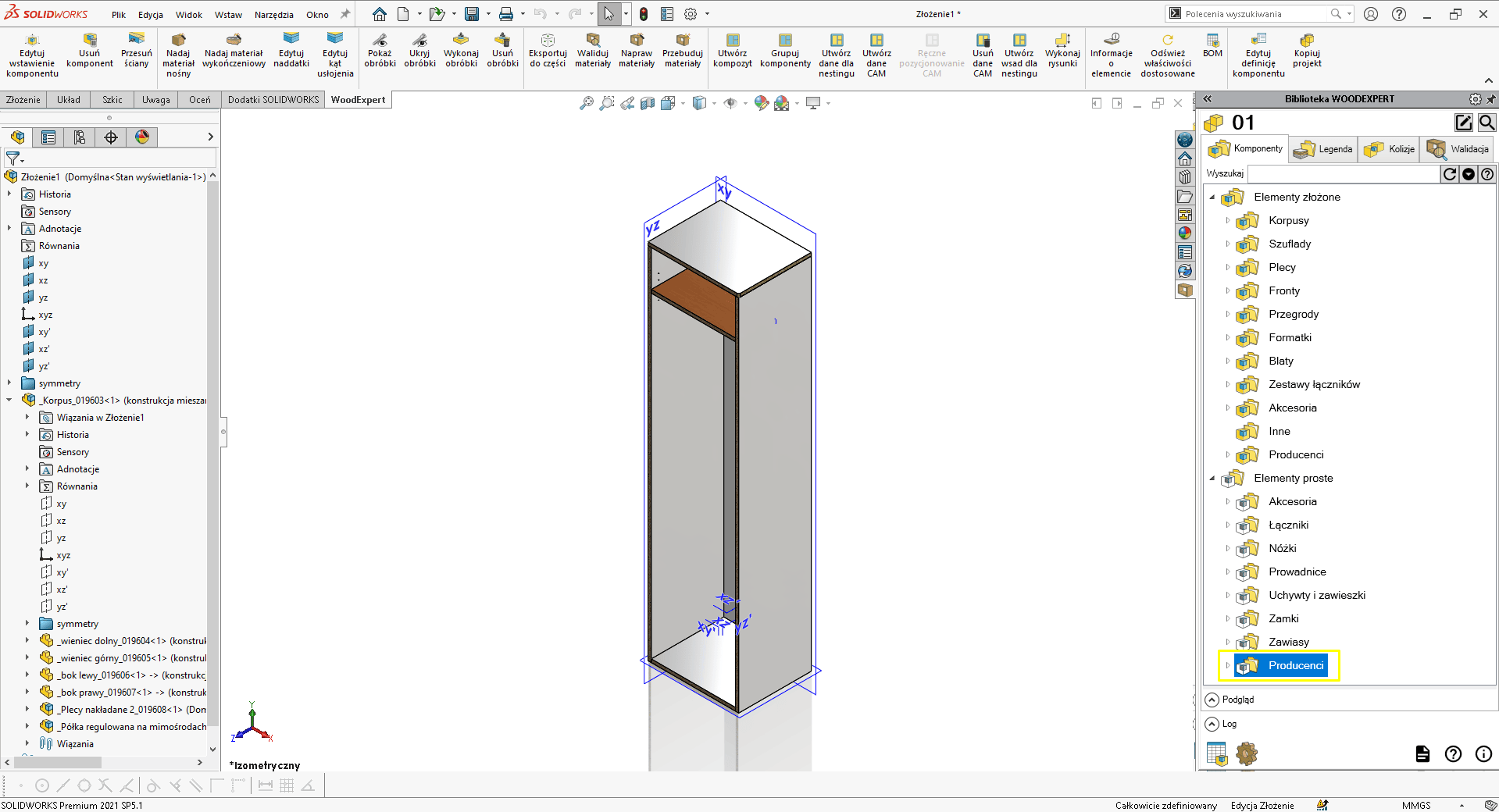

8. Use manufacturer libraries

We provide our customers with libraries from top manufacturers of furniture fittings and accessories:

- BLUM

- Hettich

- Hafele.

We update these on a regular basis, so that our customers save time importing components from external sites. You can decide for yourself which items will be included in your library, create folders from them and use them in your projects without restrictions.

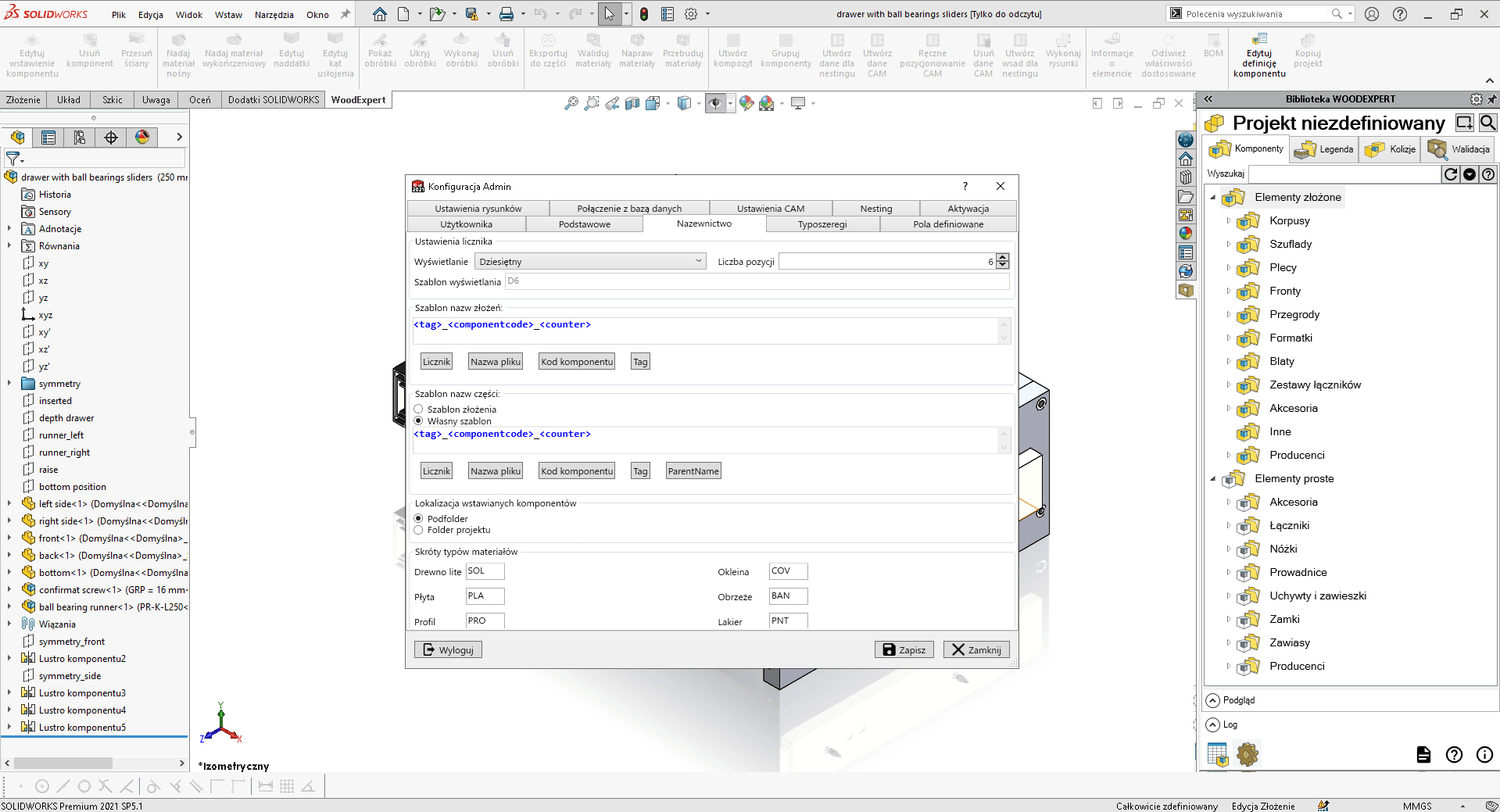

9. Decide on a nomenclature

Sometimes we adopt predetermined nomenclature in terms of assemblies, parts or materials. It is worth reminding ourselves that we can also change them and set them up to suit our specific workflow. What exactly can we change with regard to naming in the furniture planning software WOODEXPERT?

- assembly name templates

- part name templates

- abbreviations for material types.

Names are important because of their display in the material list, documentation and drawings. We can update them for the entire team as part of a change on a shared database.

10. Follow our social media for new features

As a developer of WOODEXPERT, we are constantly developing our software and introducing new functionalities. We develop them by working with specialists in the fields of furniture and CAM, among others, and we analyse the demands of our customers and the market. We keep our social media profiles up to date with the latest developments.

11. Learn new ways of working in just a few minutes

In the tutorials, we try to introduce you to the best working methods and shortcuts to get to know the software even better. The skills gained in this way allow you to save time and better exploit the potential of the available design and production tools. With users’ convenience in mind, the materials last a few minutes and are sorted into thematic playlists.

12. Earn discounts by participating in webinars

Webinars are a great opportunity to expand your knowledge in a given area, ask questions of technical specialists in person, and receive a bonus as part of your participation. Most often, these involve training courses and discounts on software purchases, which can be as high as -50% on a WOODEXPERT CAD 3D licence.

All of the above tips are a great way to develop your skills while working in WOODEXPERT and to gain knowledge tailored to your needs. An additional piece of advice arising from all of them is: keep in touch with us! Your feedback and queries are an invaluable source of development for us. This enables us to know what specialists care about and to spot new areas for development.

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…