Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

GOOD DESIGN PRACTICES: ASSEMBLIES (II)

Good furniture design practices are the basis for comfortable and efficient work of every design engineer. Please take a look at the 2nd part of our series – today we will address assemblies.

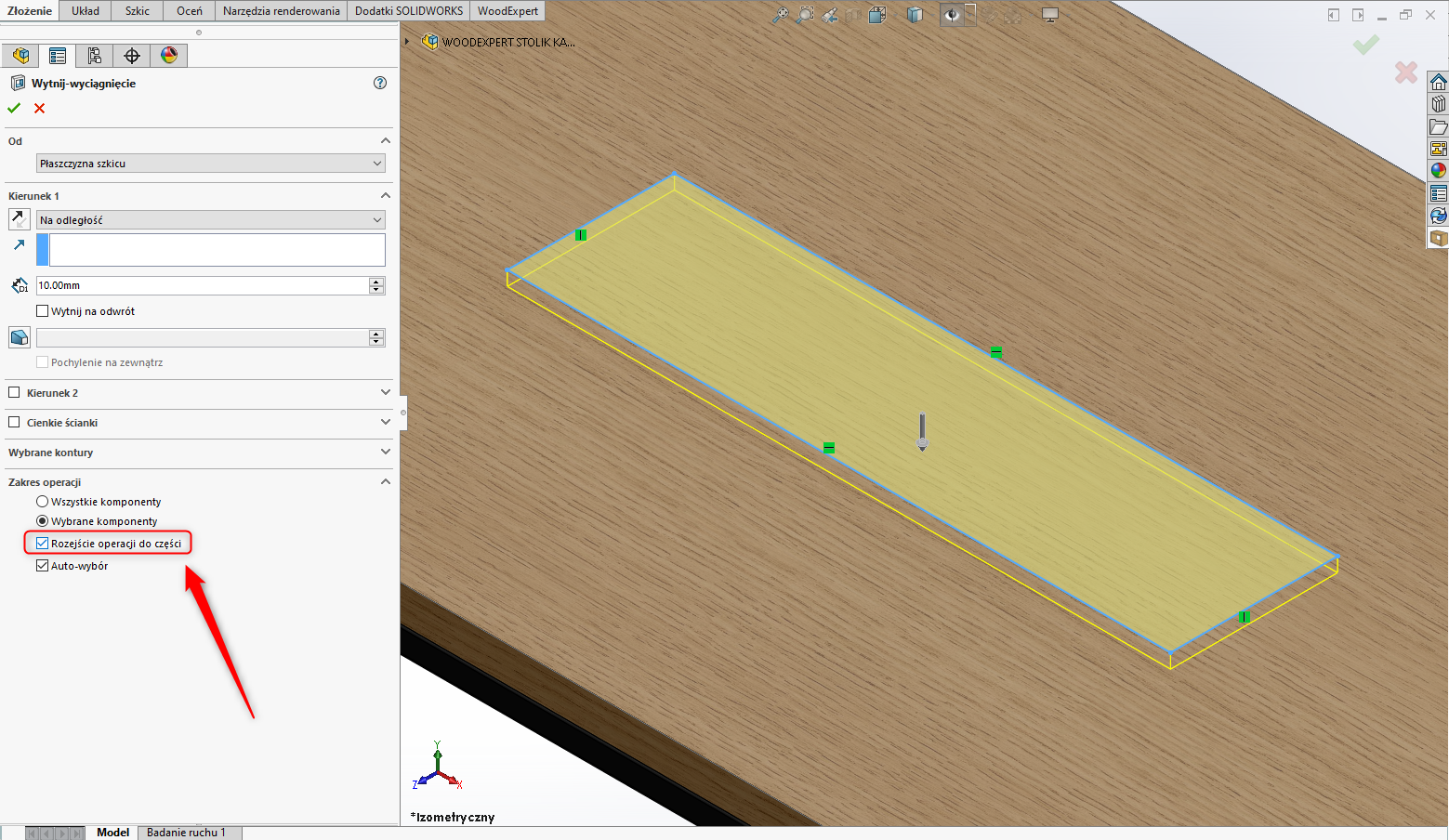

1. Make sure that all “Assembly operations” have “Distribution of operations to parts”.

Select this option to preserve the consistency of the project on the line: part – assembly. WOODEXPERT will inform you about this need, so that drawings, bills of materials and NC programs are consistent.

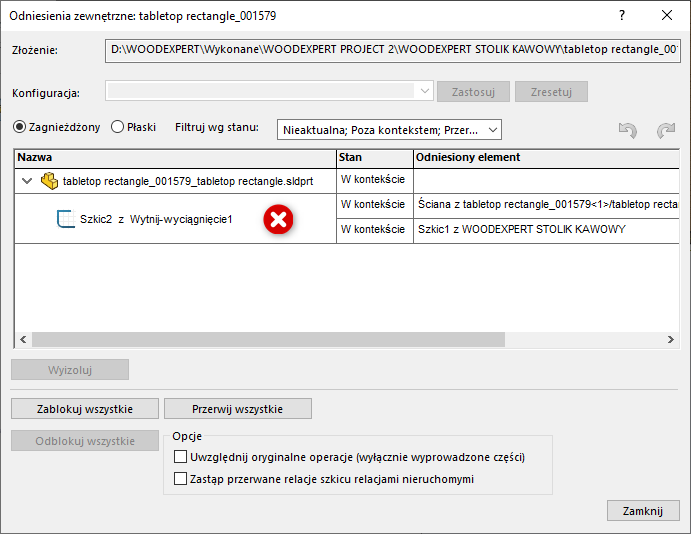

2. Limit the number of operations performed for assembly purposes.

Operations carried out for assembly include external references which will slow down the software if used in large numbers.

3. Do not insert components with import errors.

Such models may violate the structure of your project resulting in, for example, erroneous operation or displaying of geometry.

Marcin Jórasz, WOODEXPERT specialist

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…