Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

DESIGN BEST PRACTICES: PARTS (I)

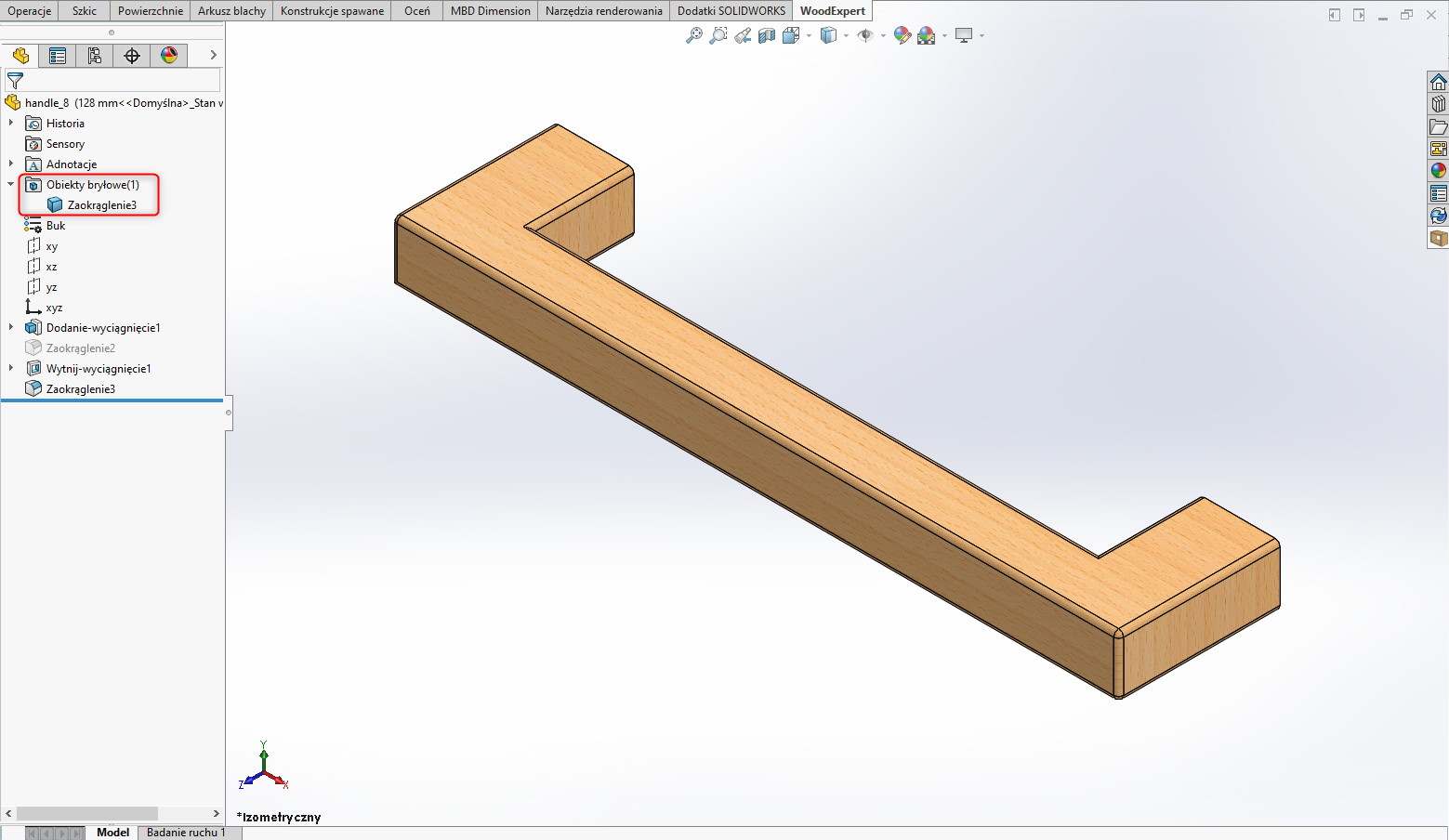

An important aspect of design is to develop good practices that will not only raise the efficiency of our work, but also increase the comfort of using the 3D software. In our series, we will present good design practices in the WOODEXPERT software for components, assemblies, drawings and designs. We start with components.

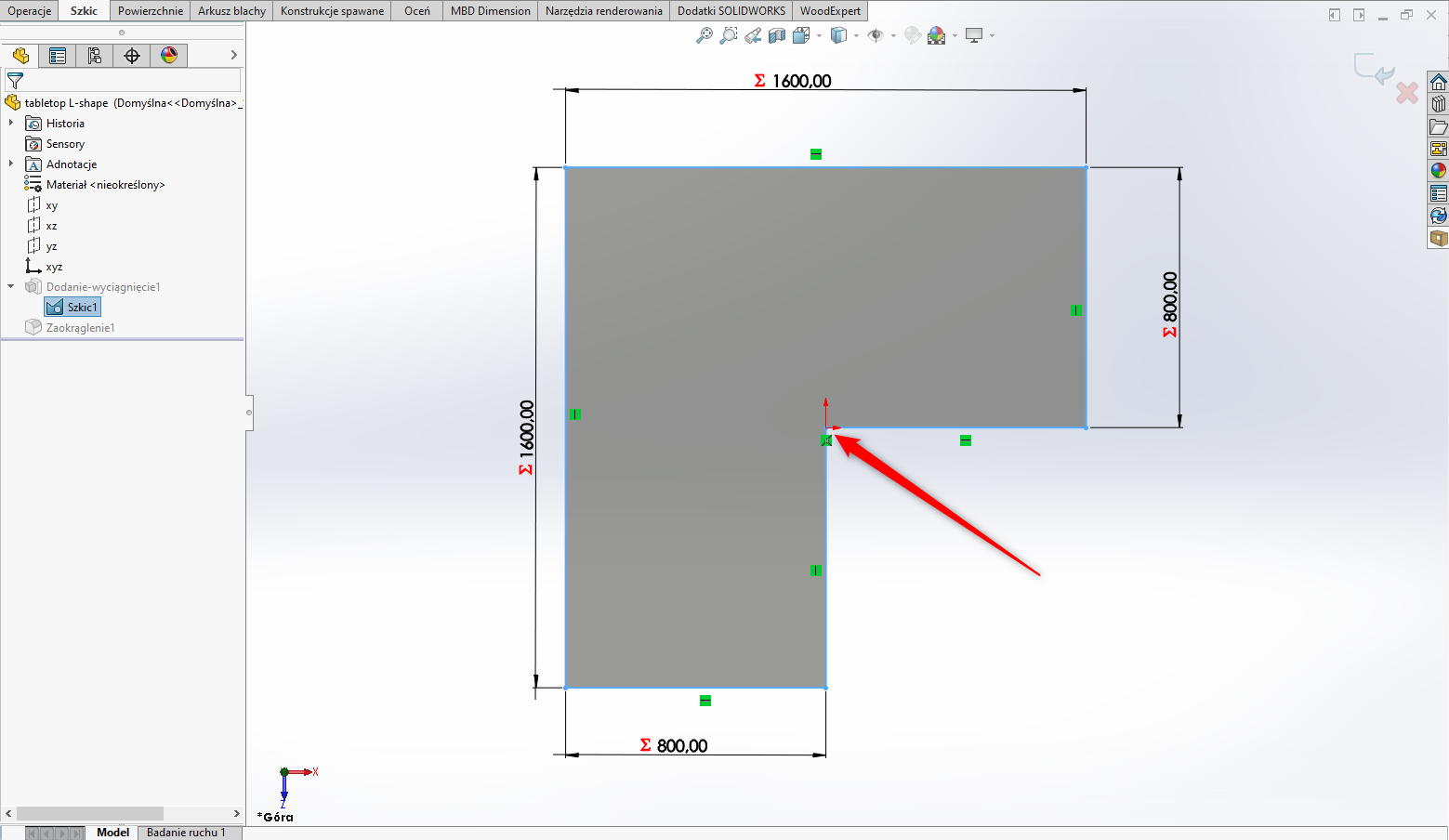

1. Remember to tie each sketch to the beginning of the coordinate system.

It’s important to get into the habit of referencing a sketch to the beginning of the coordinate system (x, y, z; 0, 0, 0) when you start working with the CAD software. This will enhance the software’s capabilities for such things as bindings, equations and CAM.

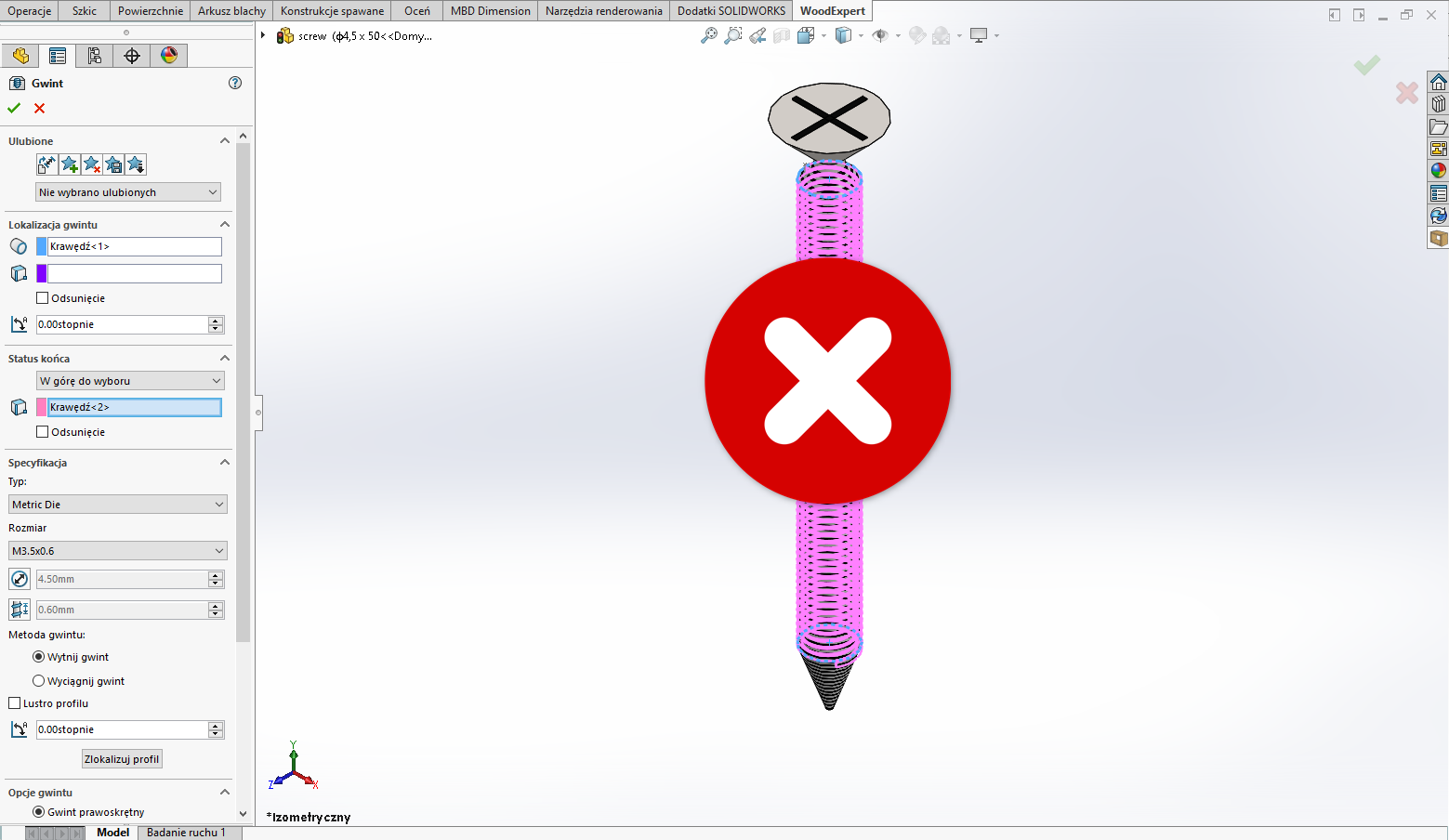

2. Simplify models as much as possible.

Simplified models will greatly increase the efficiency of your project. Avoid threads, helixes and other complicated shapes by replacing them with, for example, thread markings. That way we can get a decent performance, even on an average hardware.

For more information see the SOLIDWORKS Threads blog – info, tips – SOLIDMANIA

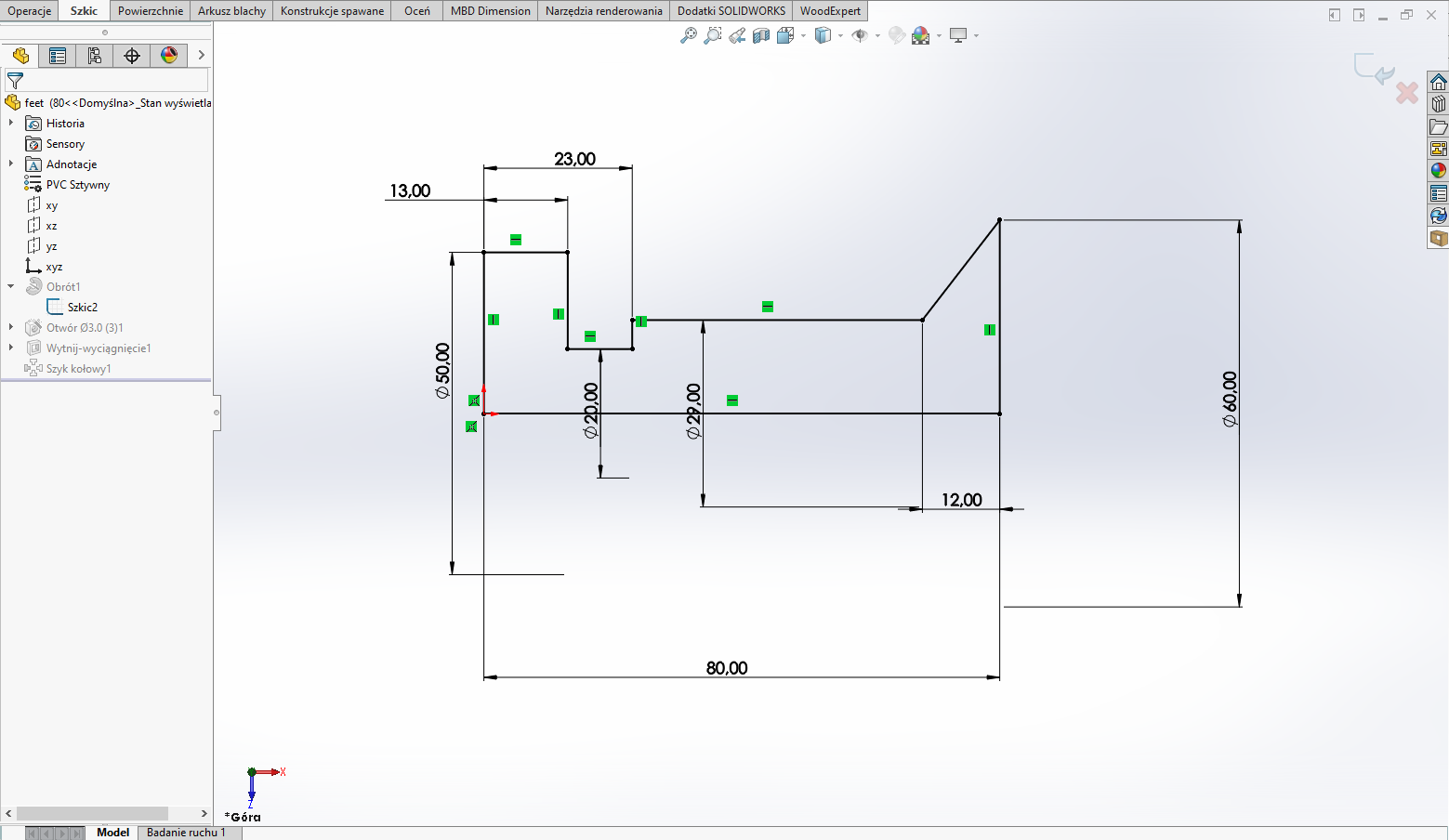

3. If possible, fully define the sketch.

A fully defined sketch will allow to easily parameterize the model and avoid design errors when editing the model. If the sketch is fully defined, all lines are black – if undefined, they are blue.

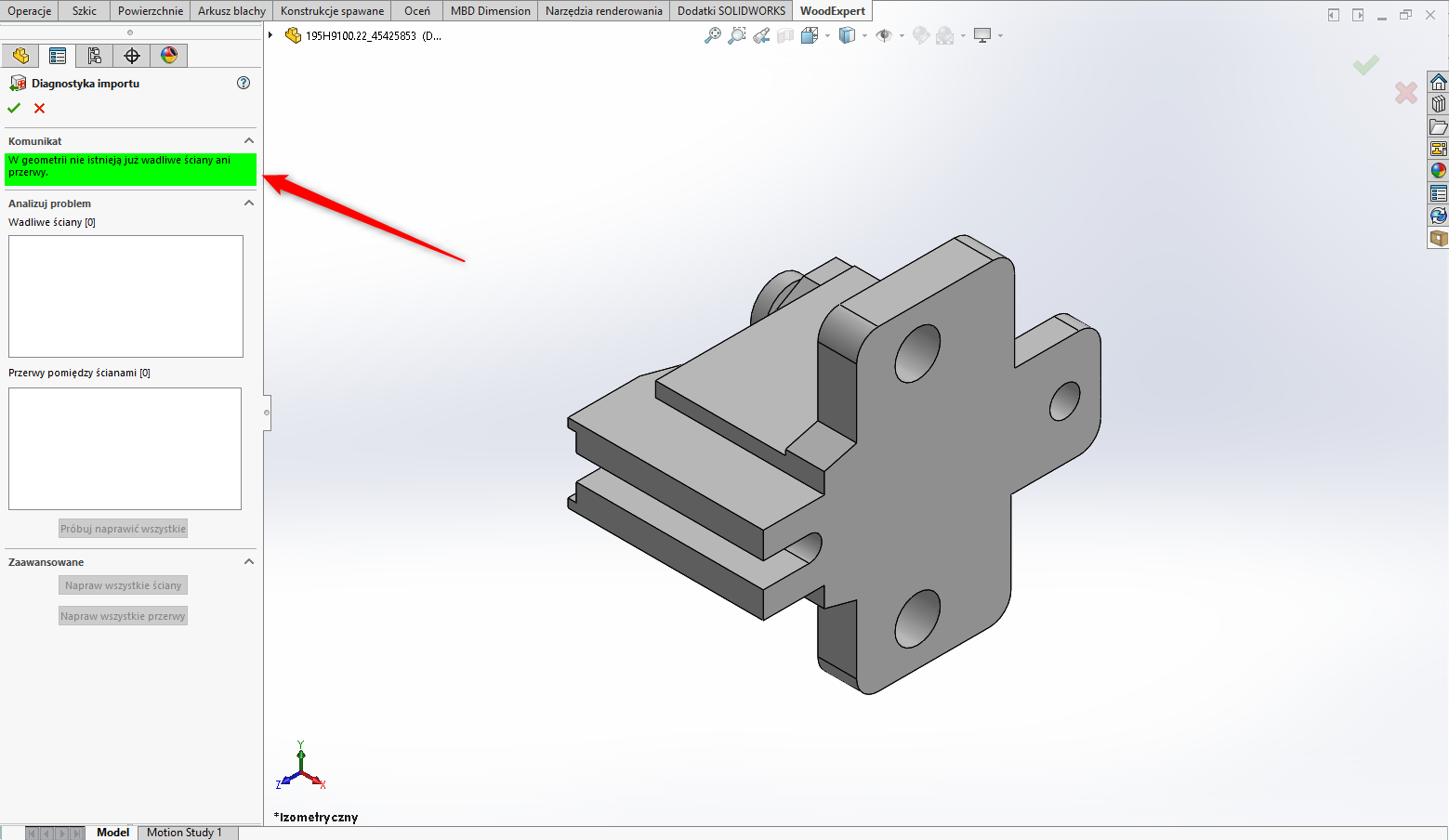

4. Fix the rebuilding and import errors.

Fix rebuilding and import errors, as models with import errors resulting from the file structure can cause the software errors and limit the operations that can be performed on them.

5. Do not model multiple-object parts.

In WOODEXPERT you work on individual objects from which you can acquire more information. Remember to follow the “one part = one object” rule.

Next week we will address design best practices for assemblies.

If you have not yet been able to test our software, please use a free 30-day test of the fully functional software – please contact us using the form on our website.

Marcin Jórasz, WOODEXPERT specialist

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…