Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

Improve your company’s performance with 19 WOODEXPERT functionalities

Special-purpose software is always a step forward to improve the performance of your company’s activities. Better work organisation, functionalities developed specifically for the industry, eliminated errors, long-term and tedious operations replaced with automatic and comfortable operation — the selection of such an option is always a win.

Discover 19 functionalities of the WOODEXPERT software to design and manufacture furniture with which your business will start to grow. Save time, eliminate errors and improve the performance of your team.

-

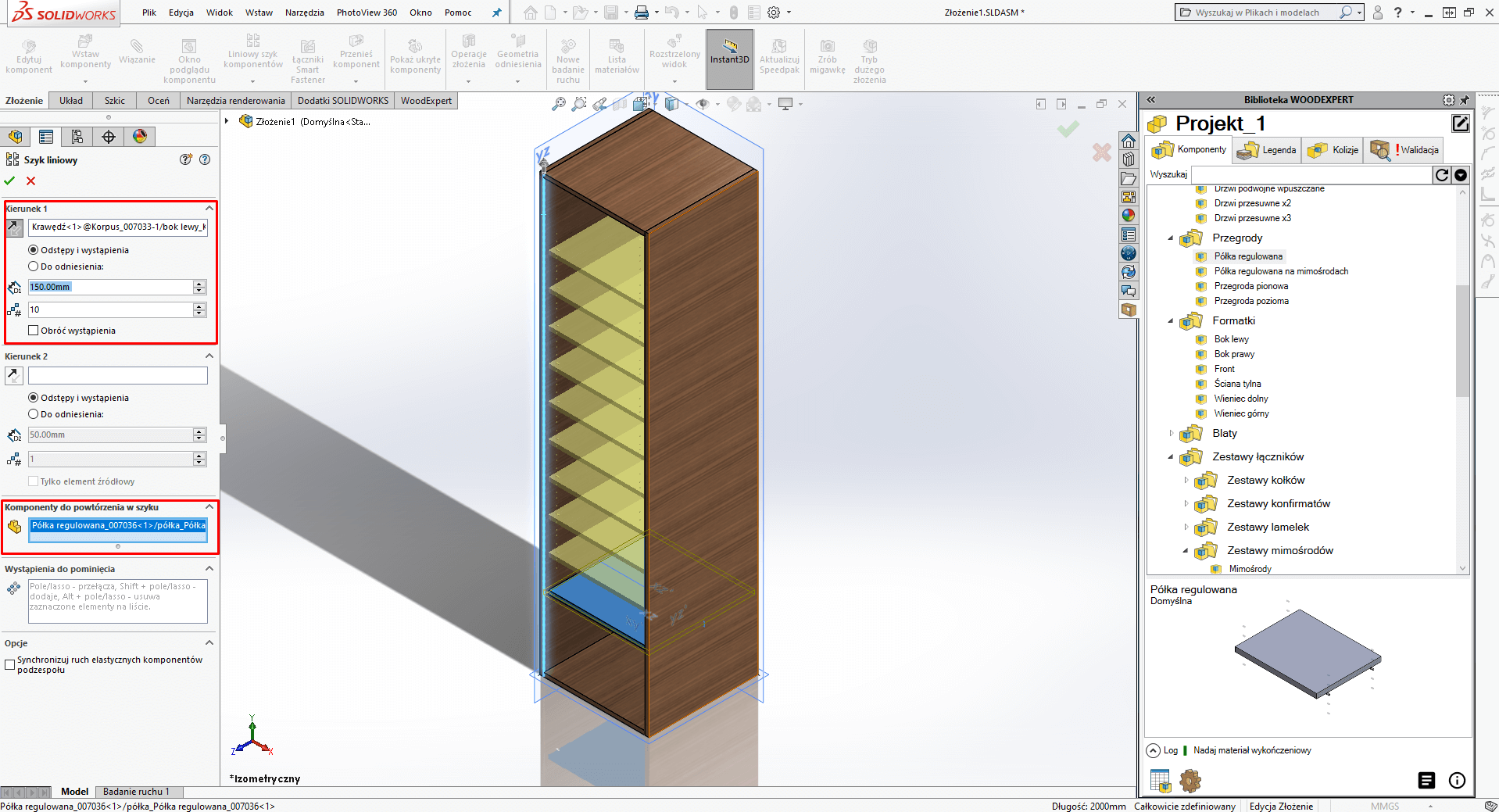

FASTER IMPLEMENTATION OF SIMILAR COMPONENTS

How to design a wardrobe with e.g. 30 shelves faster? By using WOODEXPERT’s function to implement components in a linear sequence. If the design requires using numerous identical components, select “Linear sequence of components”, determine their direction, quantity and distances between individual components. Before accepting a command, take a look at the preview and ensure that the effect meets your expectations.

-

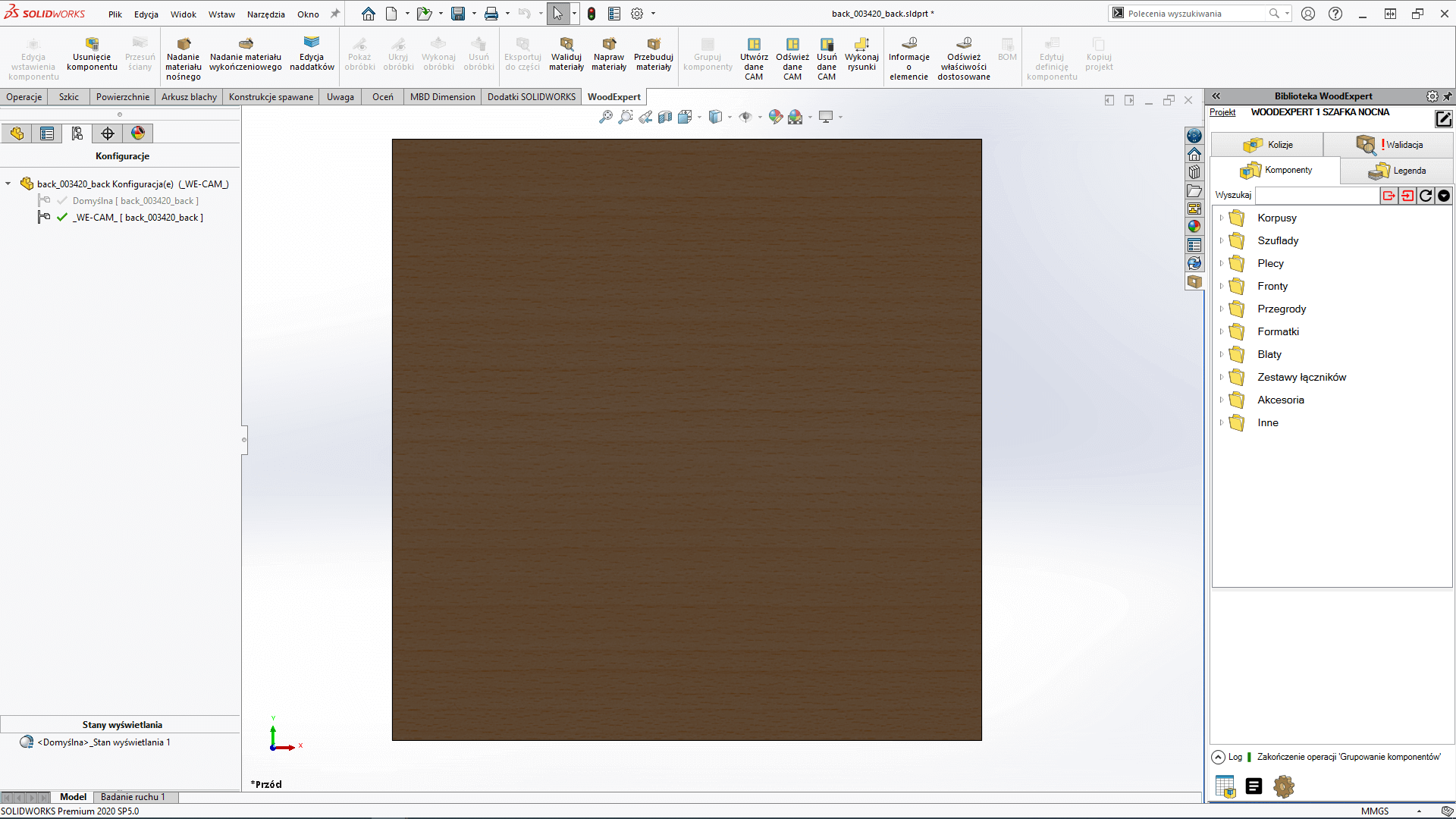

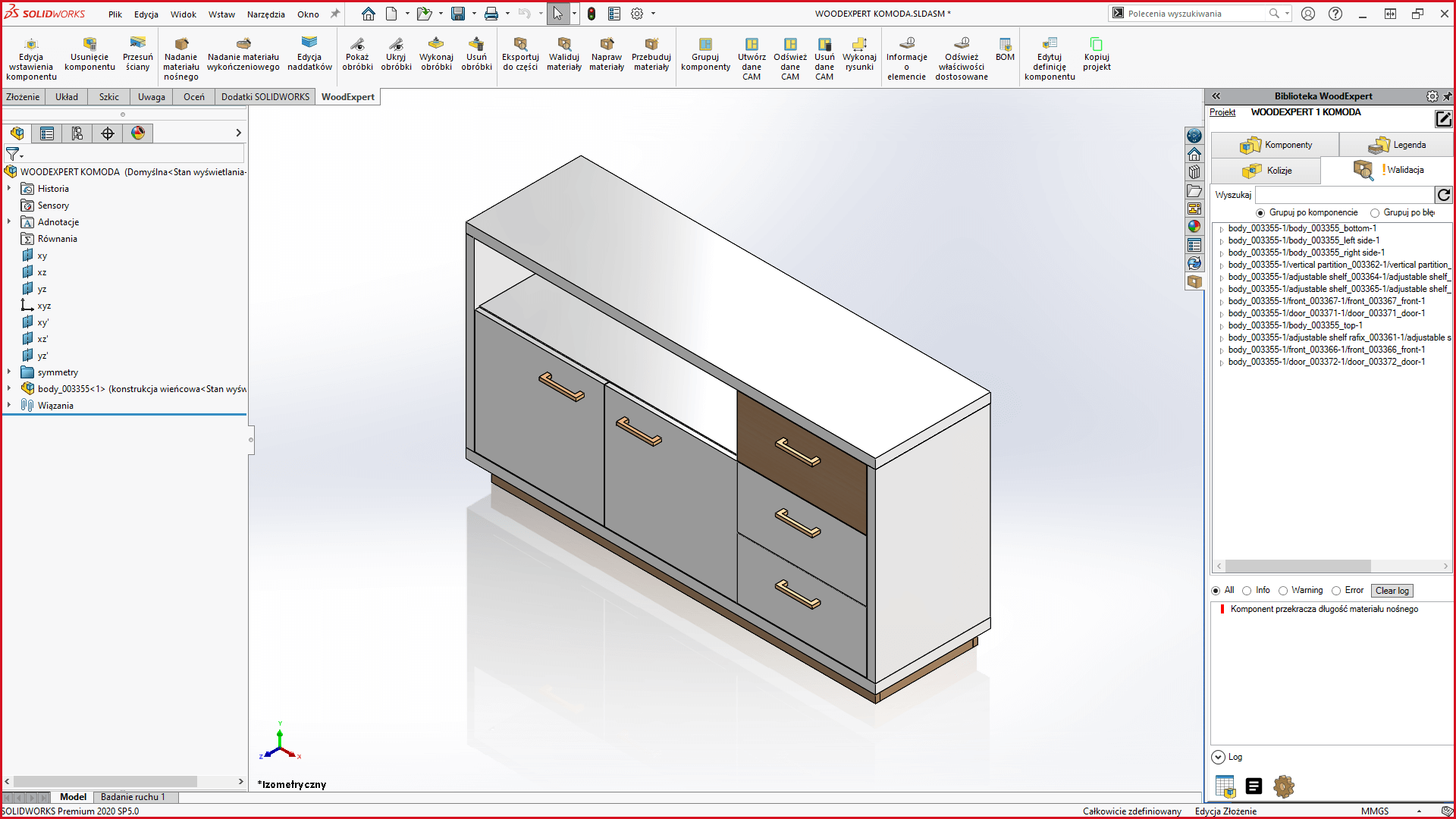

ADAPTATION OF MODELS FROM THIRD PARTY SOFTWARE

If you are planning to switch to different software and wondering whether you’ll lose your existing models — don’t worry. Models prepared in SOLIDWORKS and other CADs (e.g. in *.step., *.sat and other formats) can be easily adapted to be handled in WOODEXPERT. What does it look like in practice?

Any model created, among others, in SOLIDWORKS can be saved to the library, provided with proper parameters and treated as a new component. Additionally, by inserting e.g. a body prepared on clean SOLIDWORKS, you can start working on it at any time using all the functions of WOODEXPERT, such as the generator of drawings and bills of materials.

Another example is to create a library from a specific manufacturer’s catalog. Models downloaded from their website are easily adapted by WOODEXPERT and are subject to standard rules for the development of new components. With that, you save the time required to prepare a new library to the maximum extent.

-

EFFICIENT HIGH-VOLUME PRODUCTION

For high-volume production, you create the same furniture pieces in different colours. To avoid creating new furniture models, bills of materials and 2D documentation every time, the software has a special option to create colour options for a given batch.

-

CONTINUOUS NATURAL WOOD GRAIN

The component grouping function allows you to group selected components and separate them by a specific milling head / saw thickness. That way you get an additional template — after cutting this template you will obtain components with continuous natural wood grain.

-

QUICK COST ESTIMATE

How to prepare a quick cost estimate, especially for several options for the same design, dependant on selected variables? You enter material index and cost or select them from the search engine built in the ERP system, and the design cost will be calculated for subsequent materials and components, as well as for the entire project.

-

AUTOMATIC SEMI-FINISHED PRODUCTS GENERATOR

In WOODEXPERT you can automatically generate all semi-finished products required for machine processing. By sending to CAM not only a finished component but also a template, you will be able to choose an appropriate database in the machine and simulate milling prior to veneering.

After the settings have been properly configured, you can generate drawings that contain a frame illustrating the format, allowing for the possibility to save the dimensions of openings and other processing operations. This documentation is helpful in production plants where software is developed by machine operators.

-

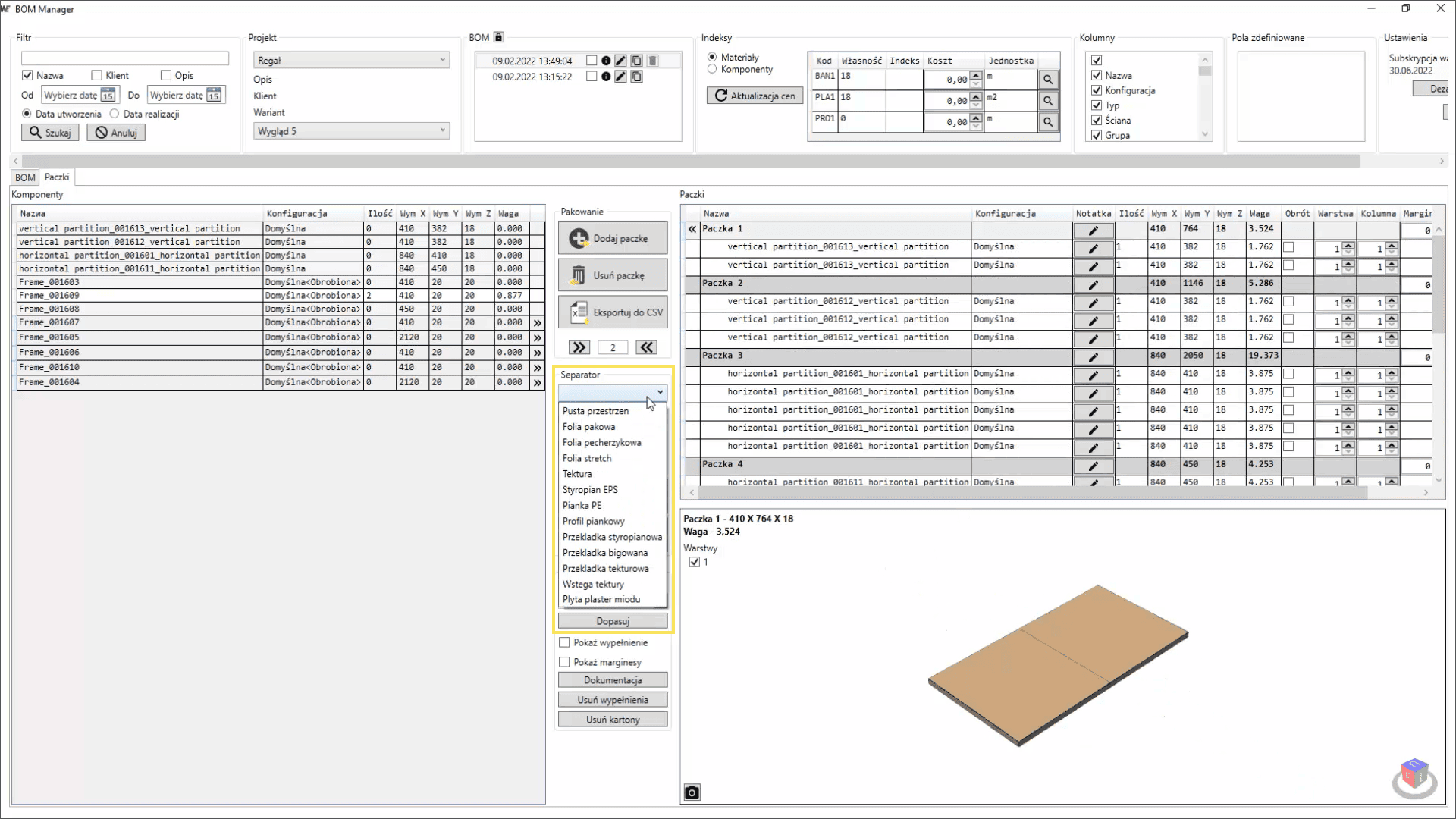

SAFE FURNITURE PACKING

WOODEXPERT also has a slightly uncommon and interesting function allowing furniture components to be arranged in a package and proper filling materials to be selected. Properly secured furniture is ready for safe storage and transport!

-

AUTOMATIC DETECTION OF PROCESS COLLISIONS

The WOODEXPERT furniture design software is provided with an advanced function to detect process collisions, facilitating their identification and allowing possible production error to be eliminated as early as at the beginning of the furniture design process.

-

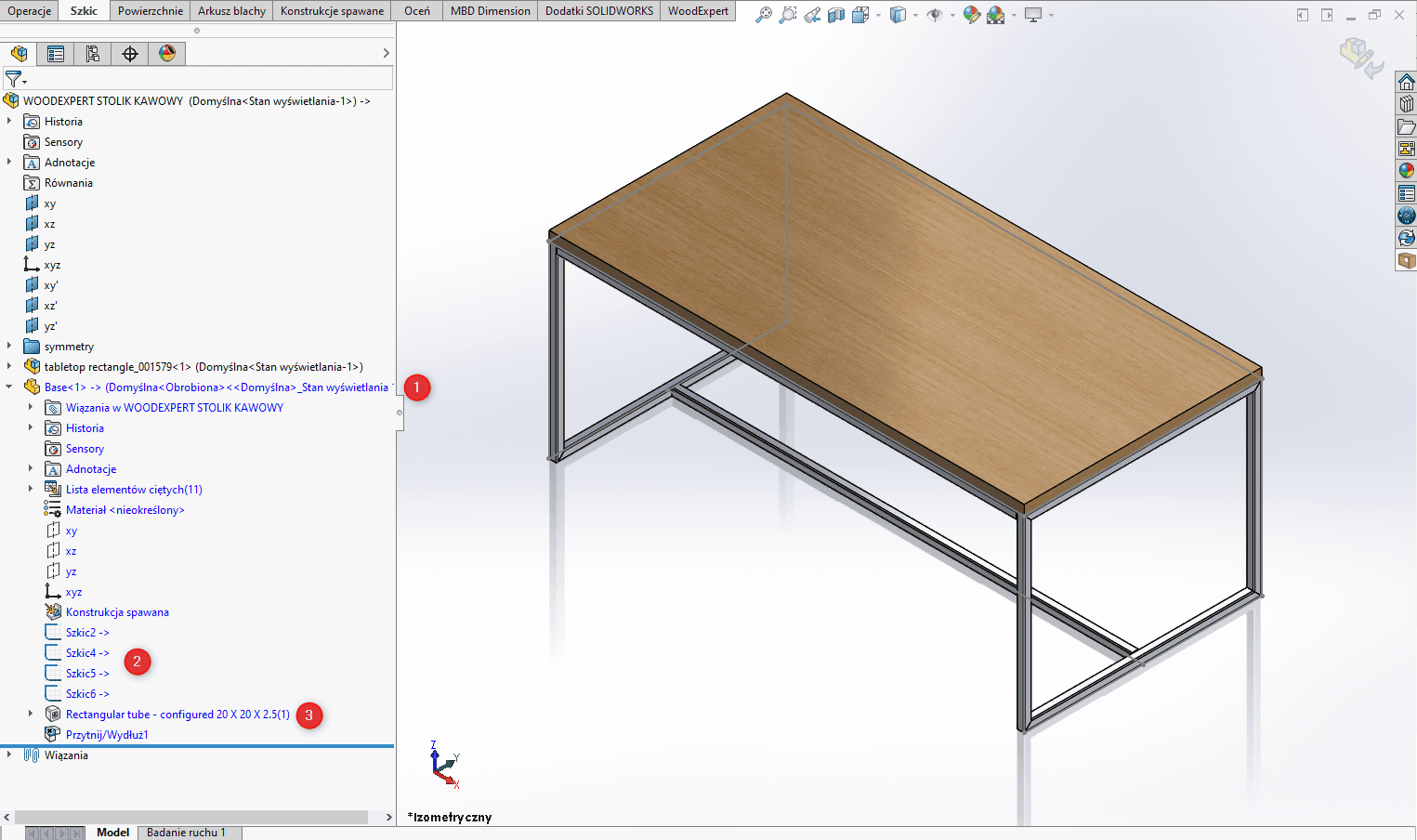

ENSURED HANDLING OF WELDED STRUCTURES

WOODEXPERT provides support for models created in the “Welded structures” module available in SOLIDWORKS to handle profiles in drawings and bills of materials. With two clicks, the user can generate drawings for all profiles and include them in bills of materials along with material and allowance details.

-

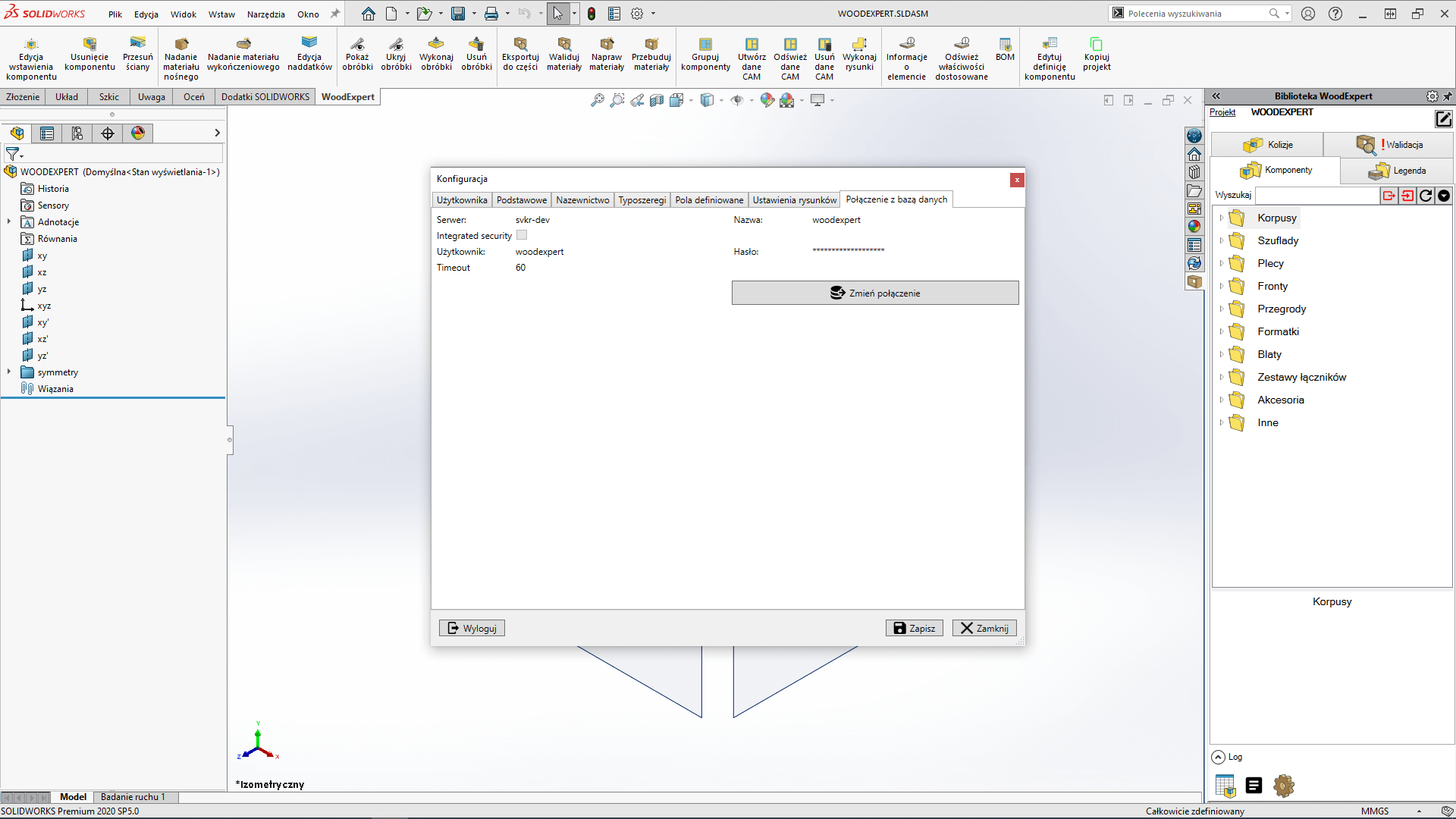

CONVENIENT SHARING OF DESIGN DATA

In WOODEXPERT, you can share data online with your colleagues, which considerably speeds up and streamlines design cooperation.

-

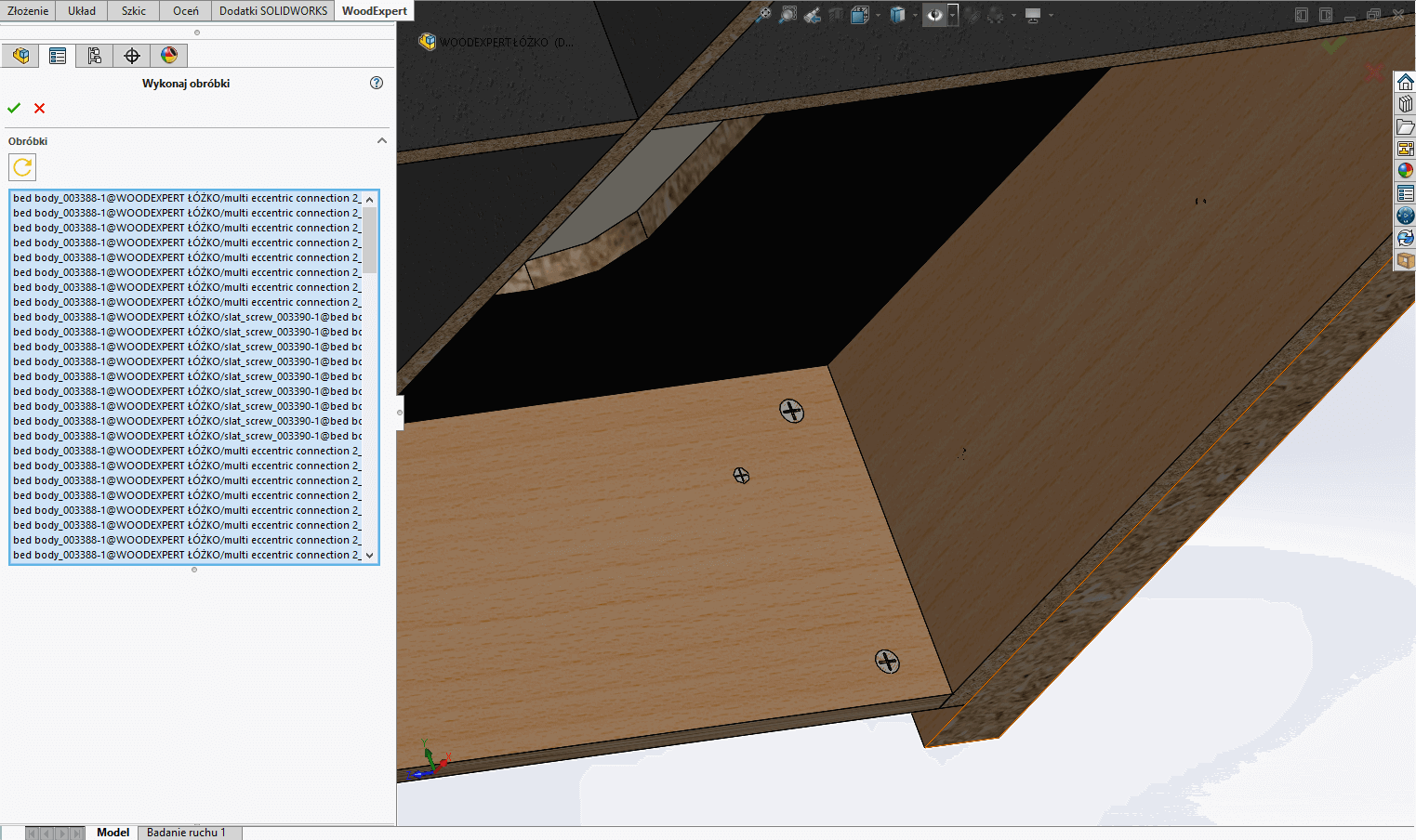

MAKING OPENINGS FOR FASTENERS IN NO TIME

Making openings for fasteners is usually a difficult and time-consuming process. It involves time-consuming operations, with every change requiring a repositioning. The same applies to inserting proper hardware and accessories into openings. With dedicated WOODEXPERT functionalities, the duration of both of these processes is reduced to the minimum.

-

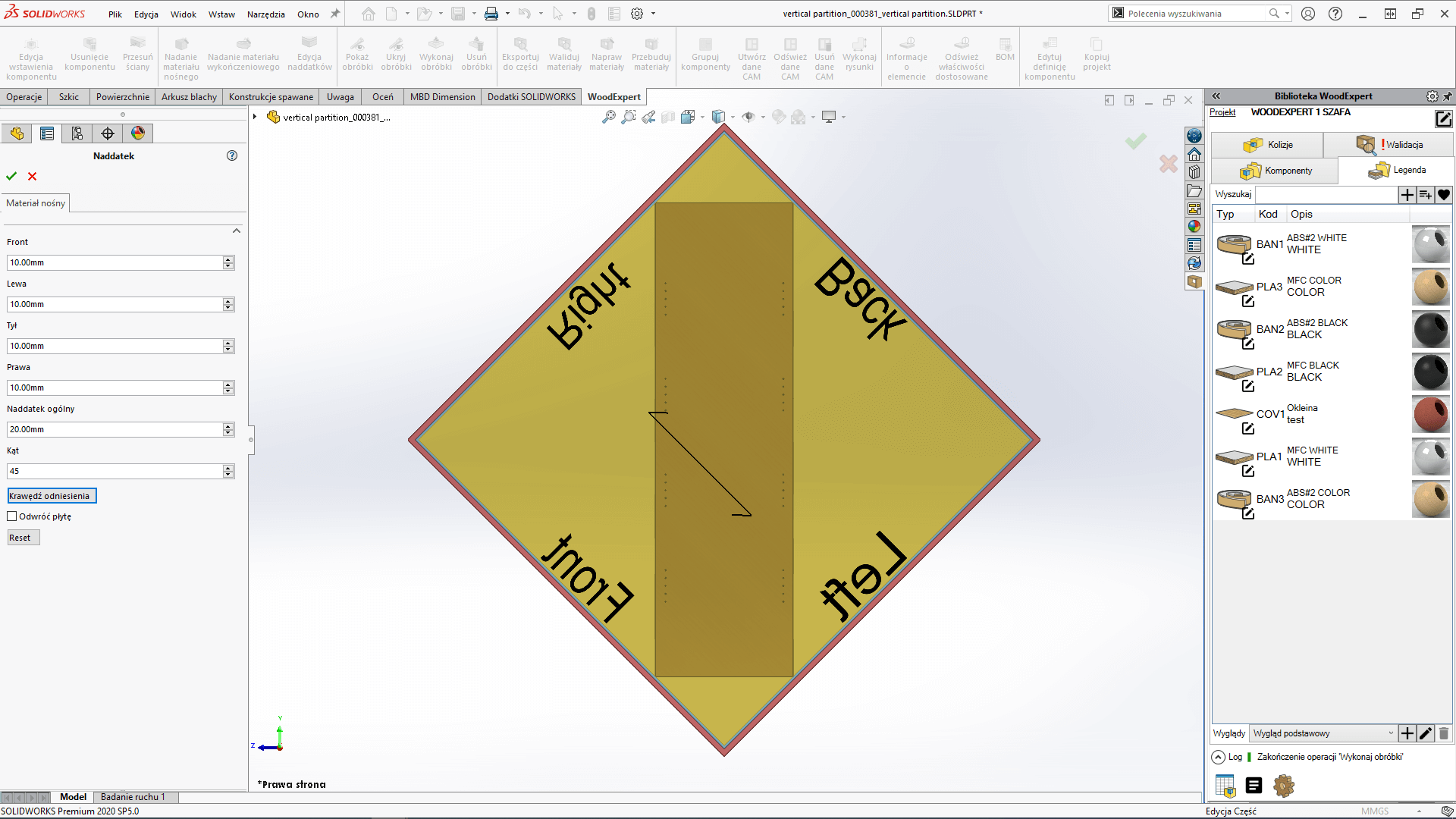

EDITING PROCESS ALLOWANCES

With this function, you can control process allowances and wood grain angle. Process allowances in the furniture industry differ significantly from allowances in other industries. Standard process industries are assigned by default to the materials in the legend, but the need to change each component individually also occurs frequently. In this case, you can use the “Edit allowances” function which not only allows you to edit, but also reassign them.

-

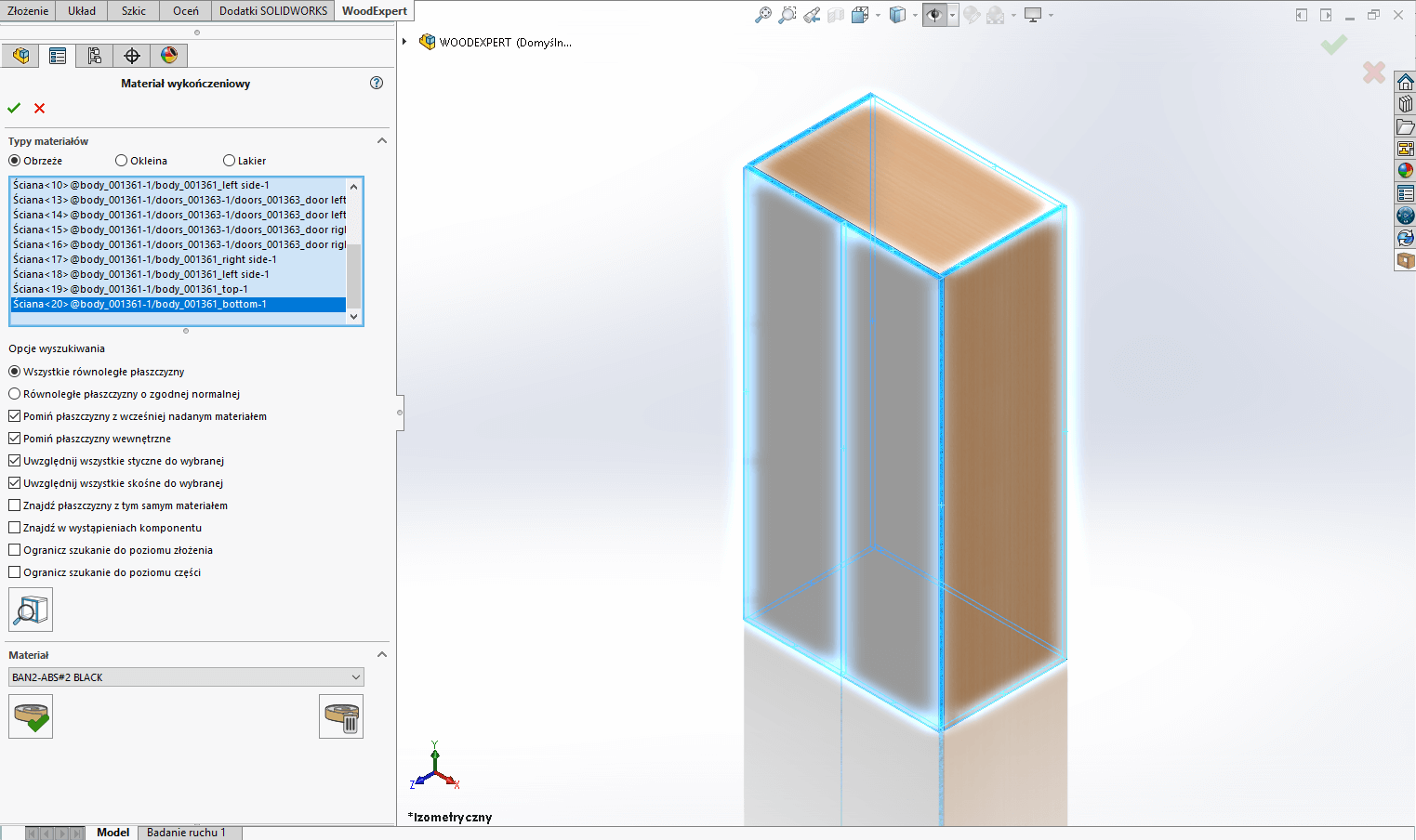

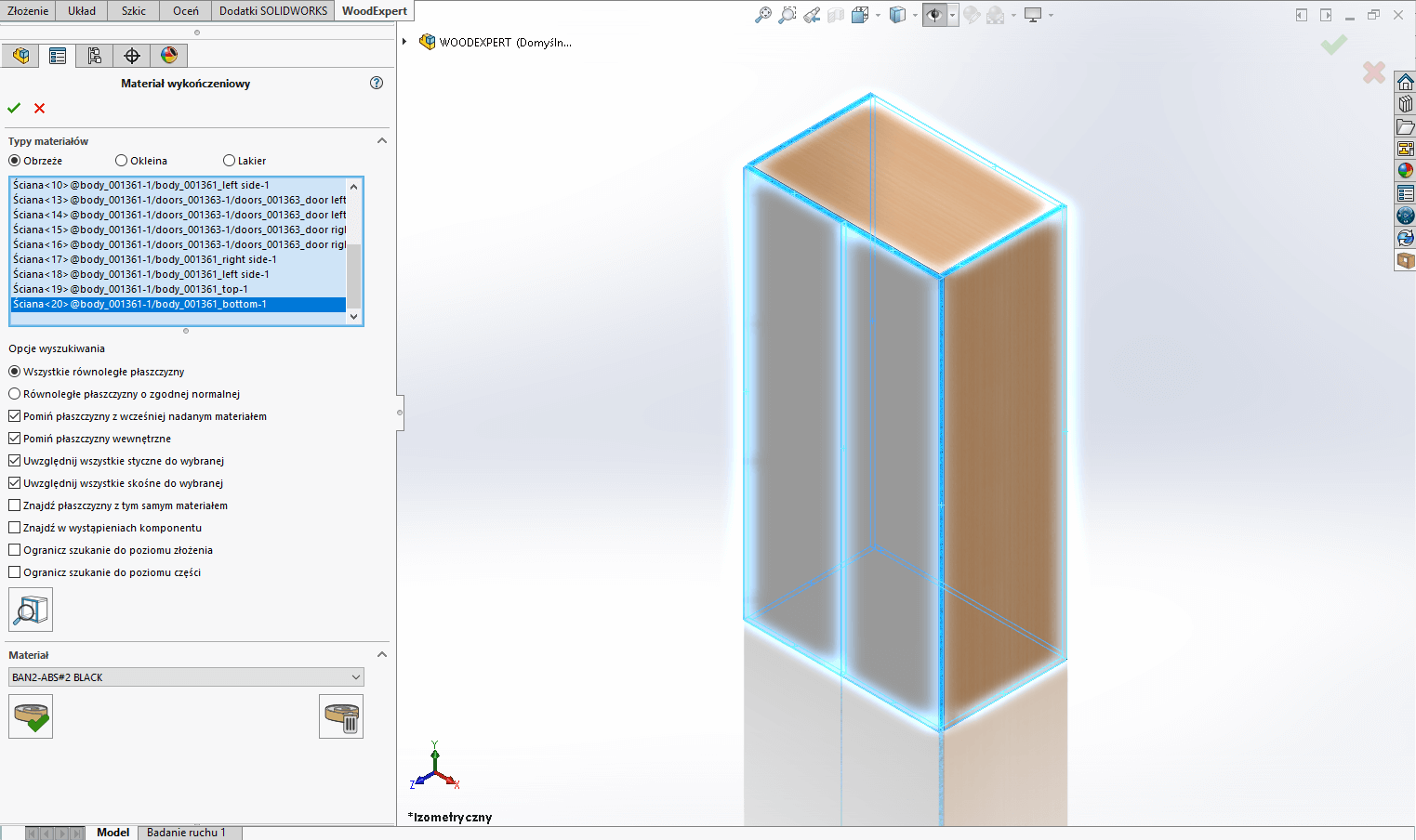

SMART ASSIGNMENT OF SUPPORT AND FINISHING MATERIALS

With the function of smart assignment of materials, the user can assign support and finishing materials to corresponding surfaces with a single click. The automatic selection can be, of course, supported manually — by adding or removing selected edges and surfaces. The time spent to assign support materials or model edging manually is reduced to just dozen plus seconds.

-

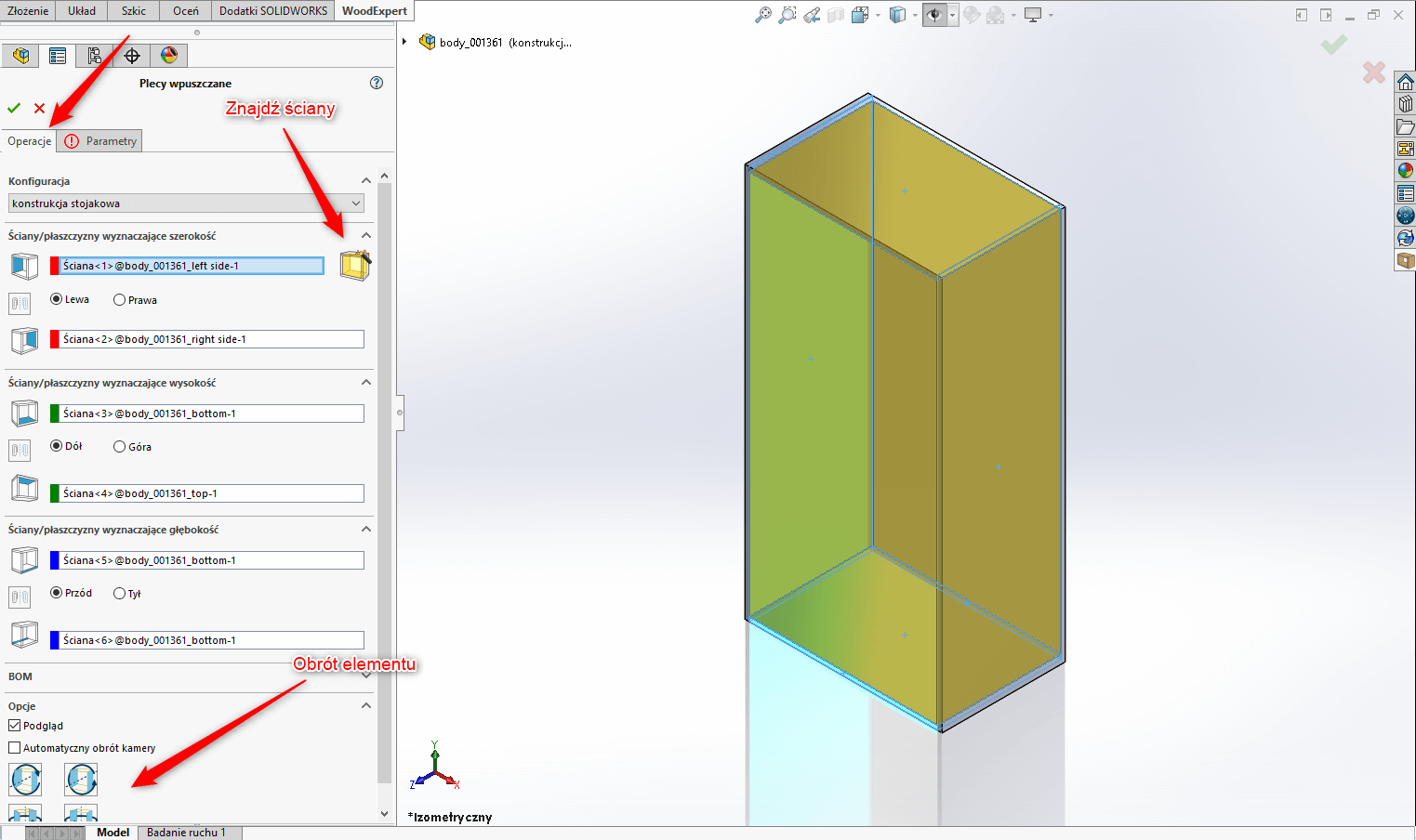

SMART COMPONENT INSERTION

This function ensures maximum reduction of the time taken to insert furniture components. An important element of the component insertion process is using the OpenGL preview which allows space for the insertion of a given component to be determined. OpenGL has been developed from scratch by our team with the sole intention to make furniture design in WOODEXPERT a pure pleasure.

-

FAST ASSIGNMENT OF SUPPORT AND FINISHING MATERIALS

An efficient process of assigning support and finishing materials, free from errors in surface selection, can be performed thanks to material group search. By using a dedicated search engine in WOODEXPERT, you can flawlessly assign a material, e.g. to all plate components excluding the front, assign edging to the front or the door only, omit edging assignment to a selected panel component, etc.

-

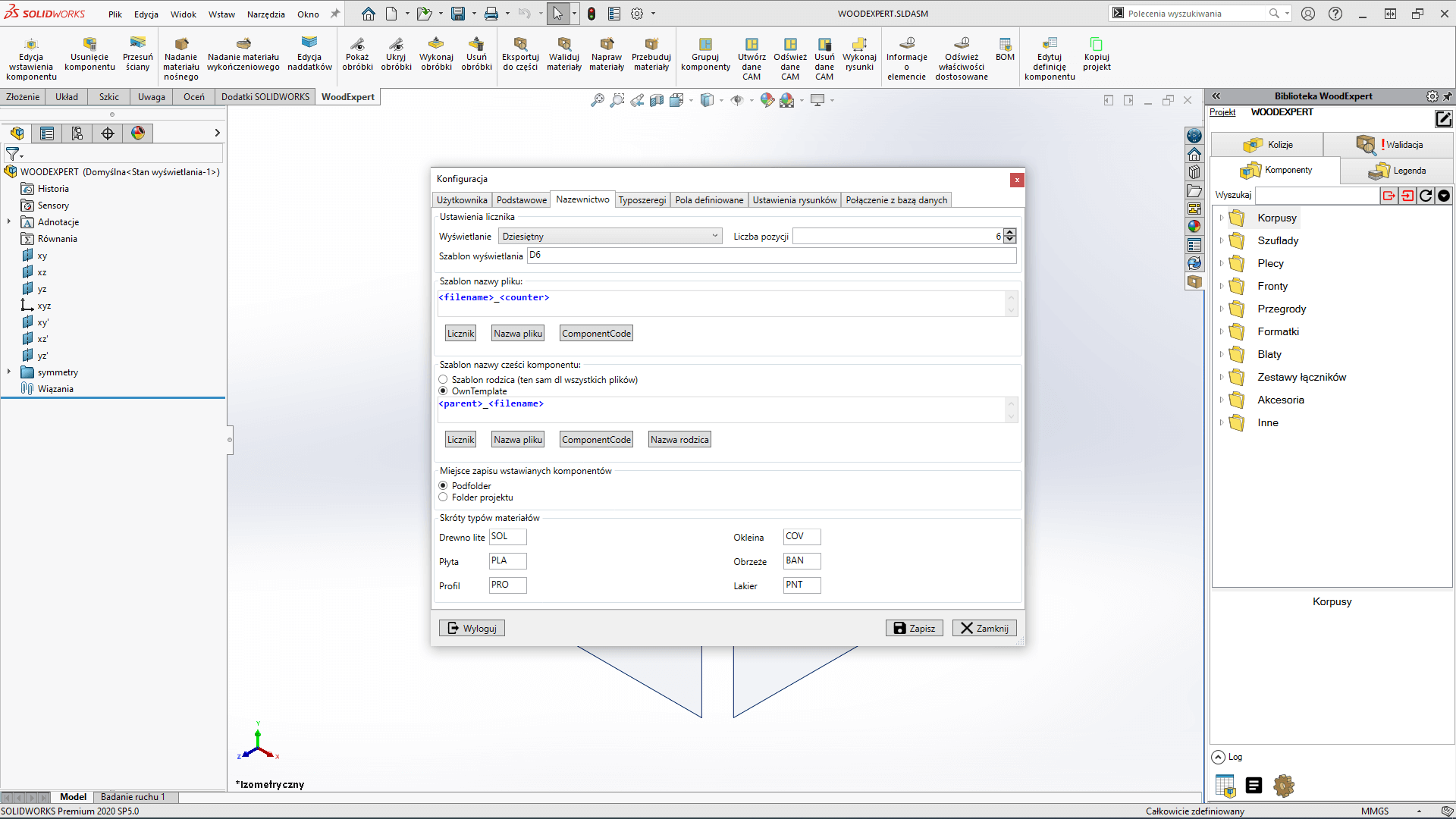

NO MORE CLUTTER IN FILE NOMENCLATURE

We have introduced a file name mask to the software settings. The mask allows for an accurate naming scheme for new files to be determined, while maintaining separate nomenclature of part and assembly files. Additionally, the administrator can establish a naming scheme for new materials. As a result you have a coherent, comprehensible and, what’s most important, unique nomenclature for the generated data.

-

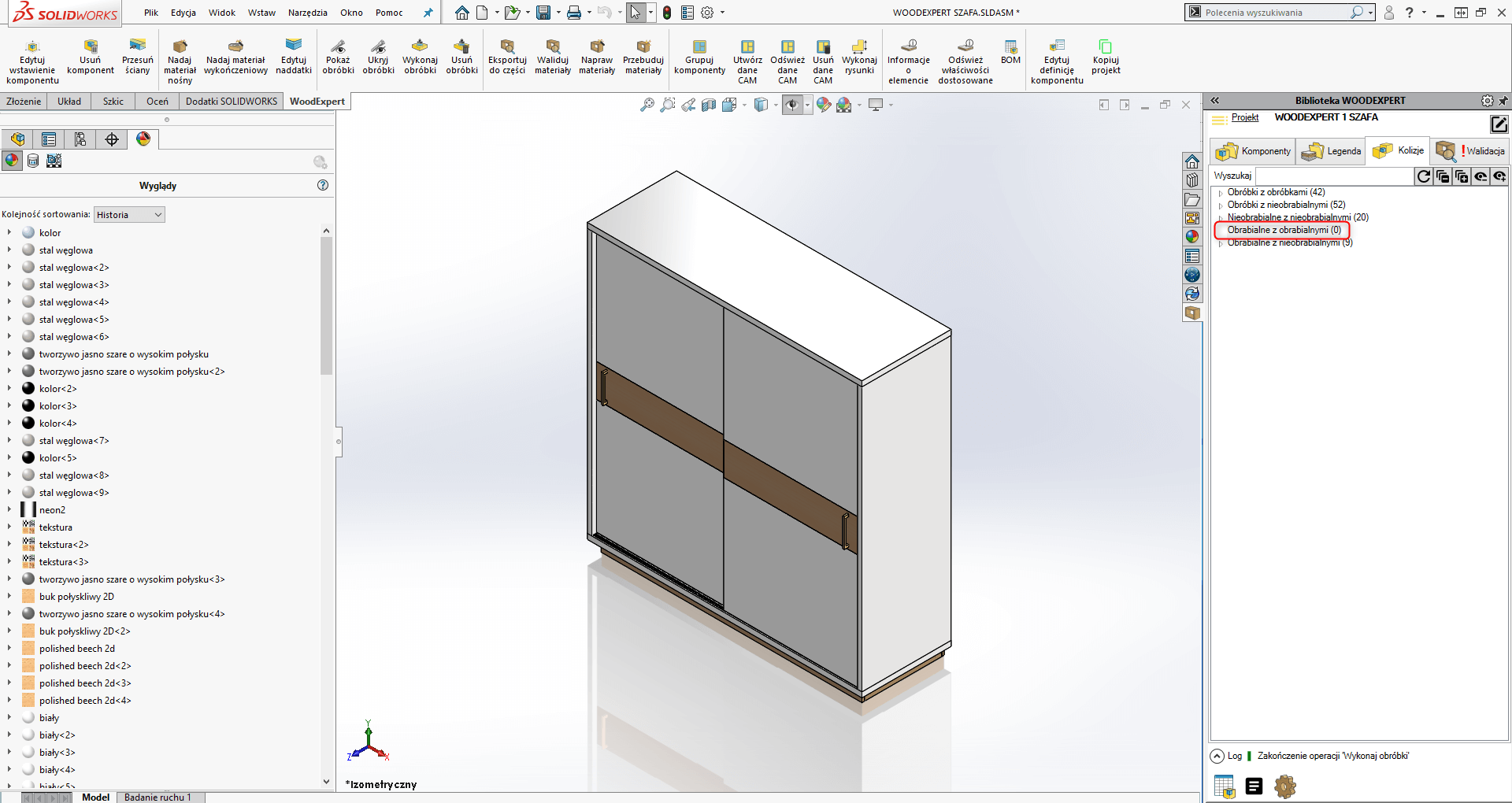

VALIDATION OF MATERIALS AND GEOMETRIES

Each furniture model is verified for correctness of the assigned materials, textures and processing.

-

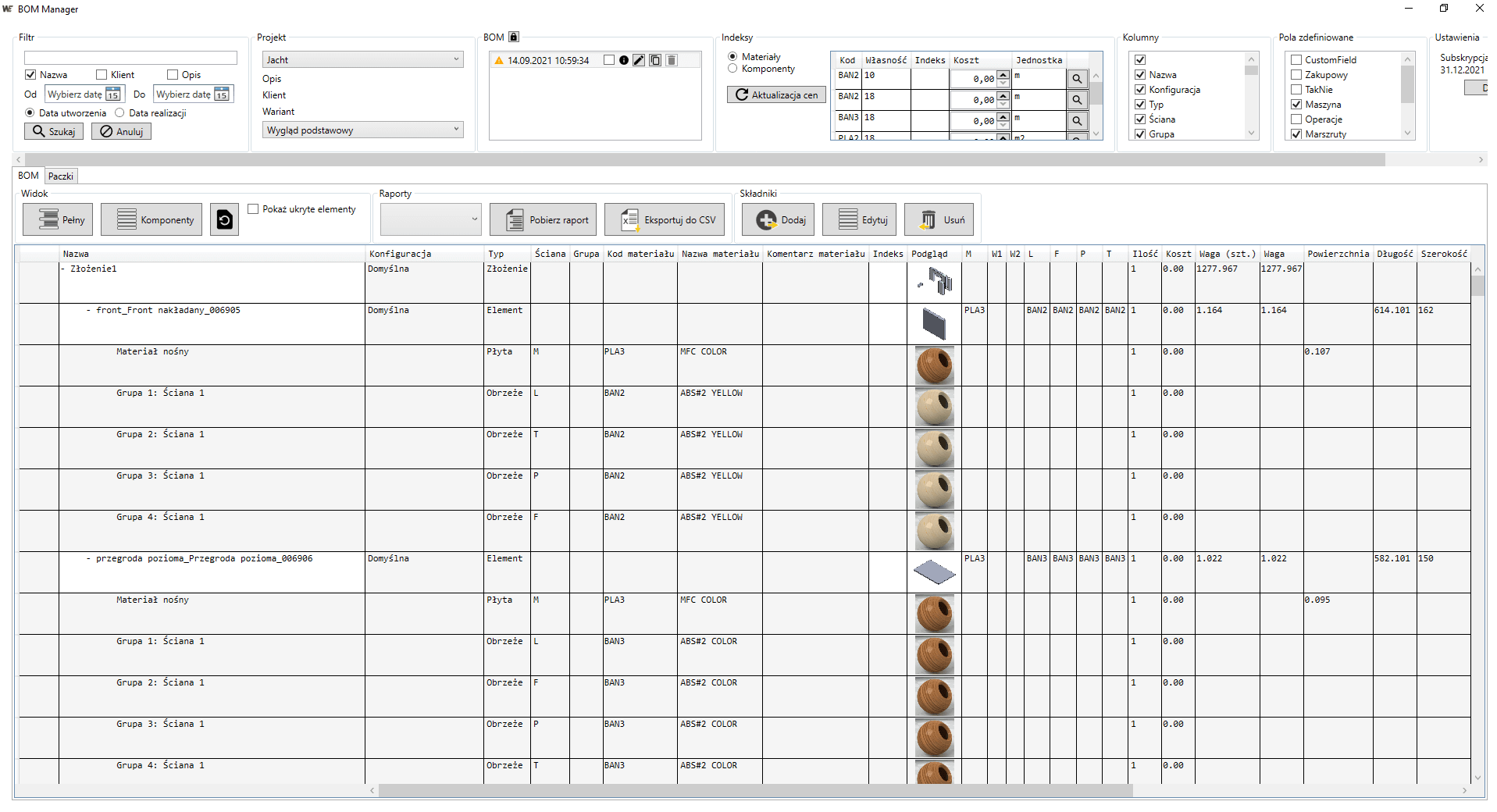

DRAWING AND PRODUCTION DOCUMENTATION

This special-purpose software for the furniture industry transforms time-consuming and tedious drawing into a single click. As a result you obtain a complete 2D documentation, which saves up to 90% of your time. For large-scale projects, this is of utmost importance. Production reports generated on the basis of the data from the model and BOM Manager make it possible to export the data to any file and scheme type, including the data transmitted to ERP systems.

-

INTEGRATED ENVIRONMENT

Within the integrated environment, you can use tools that come with SOLIDWORKS, including SolidWorks CAM which can be extended by a Nesting module.

We have reached the key point — are the above lines just the marketing talk? There is only one way to find out, and, no, it’s not asking strangers on online forums — just download the trial version of the software. You have 30 days to see how useful this highly specialised CAD tool can be for your company.

If, however, you are one of the people who prefer step-by-step explanations, use the contact form and the “Order online presentation” option. The entire online (or on-site) meeting lasts approx. 1.5 h — during the meeting you will get familiar with the software and receive answers to all your questions. Why wait? Download now.

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…