Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

How to design yacht furniture?

How does the design of yacht furniture look like in the WOODEXPERT specialized CAD software? We encourage you to follow the entire process, step by step.

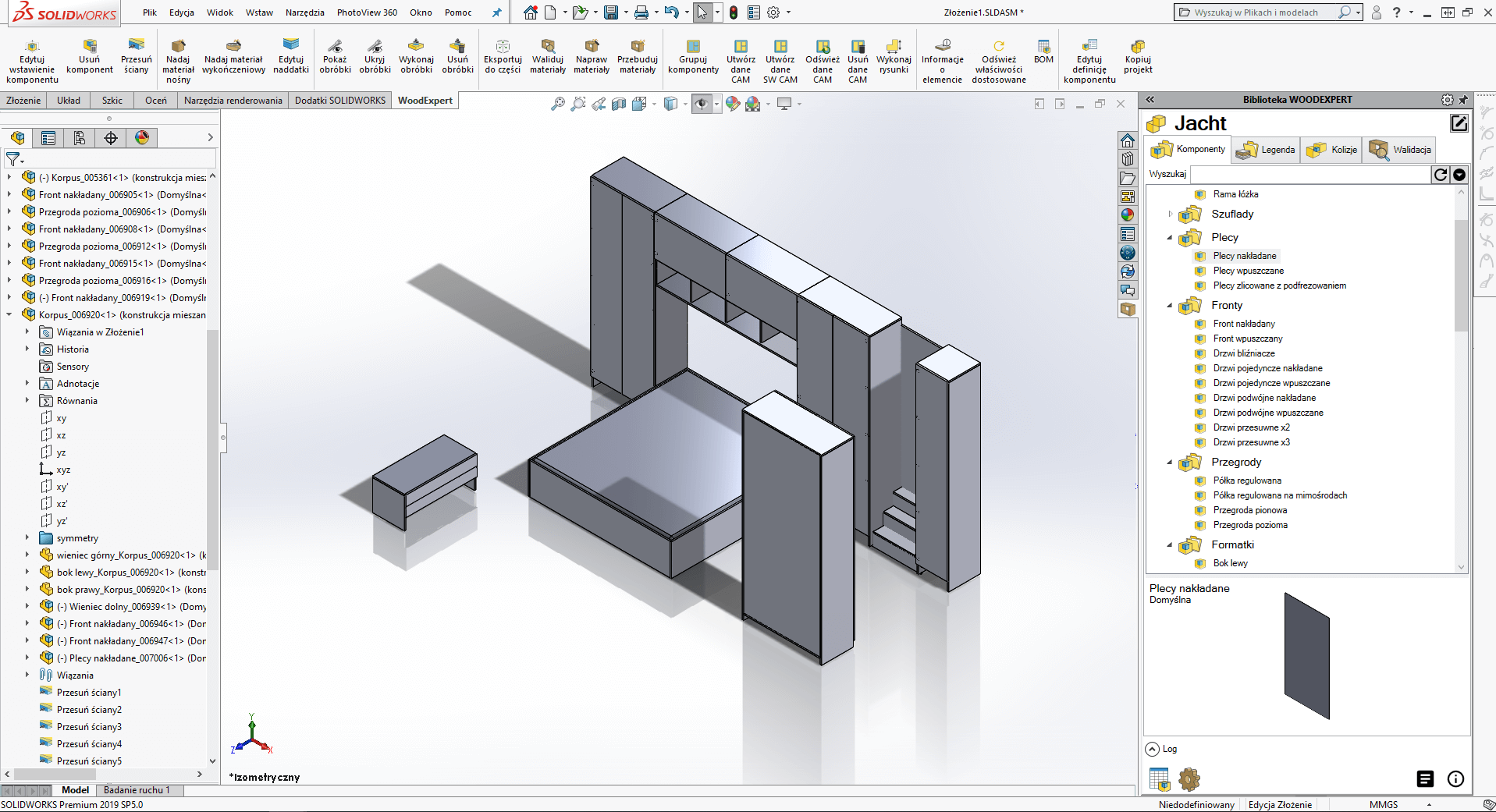

Furniture design and production include not only standard box furniture, but also customized solutions. Yacht furniture must perfectly fit to the cabin interior and have the required safety parameters and high fabrication quality. To optimise production costs and plan the course of production, a dedicated software is required. The answer to the needs of designers and manufacturers of yacht furniture is the specialized 3D CAD software WOODEXPERT which enables the entire process: from designing, creating production documentation, adjusting material lists, and preparing CNC machining.

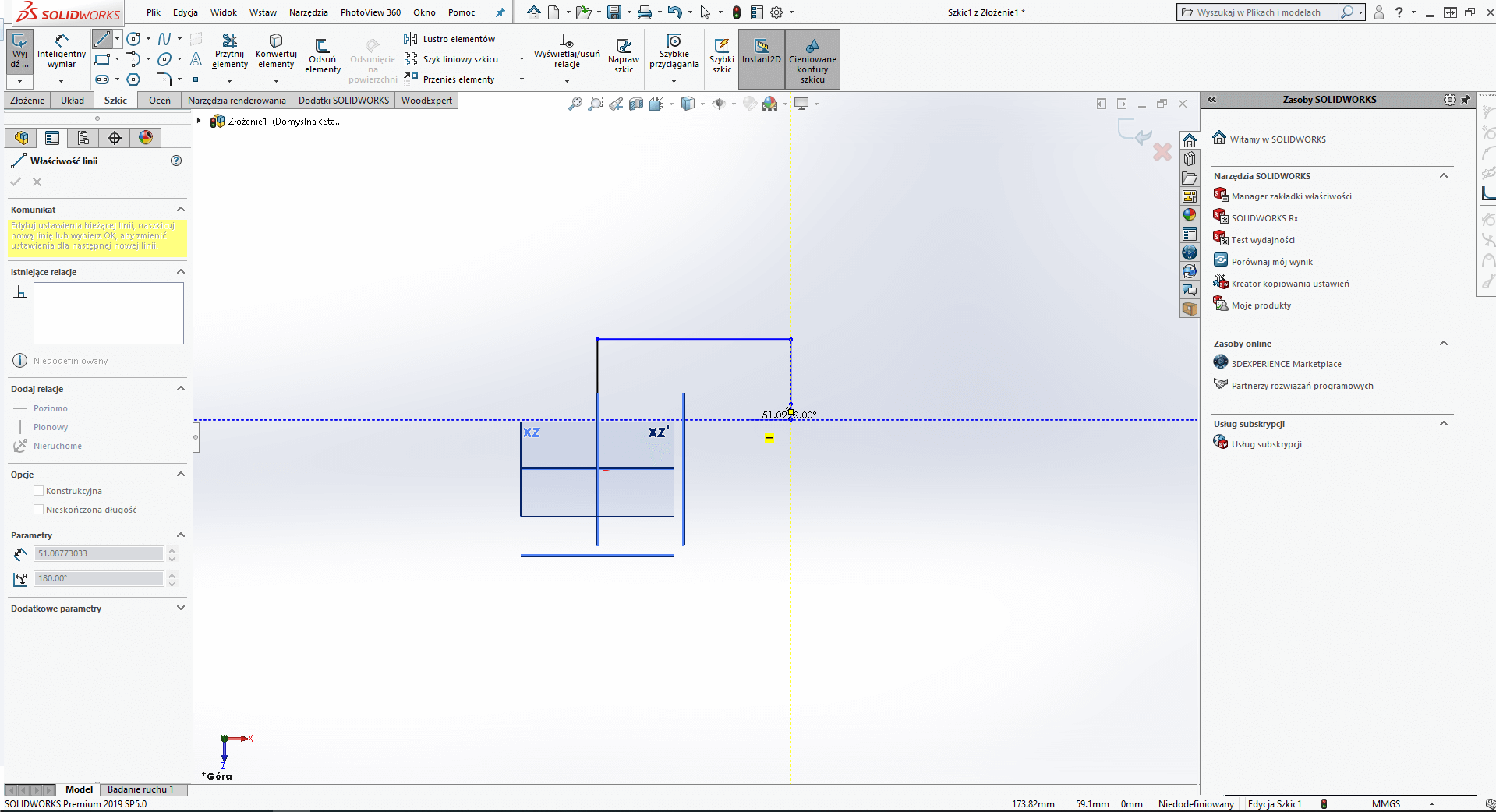

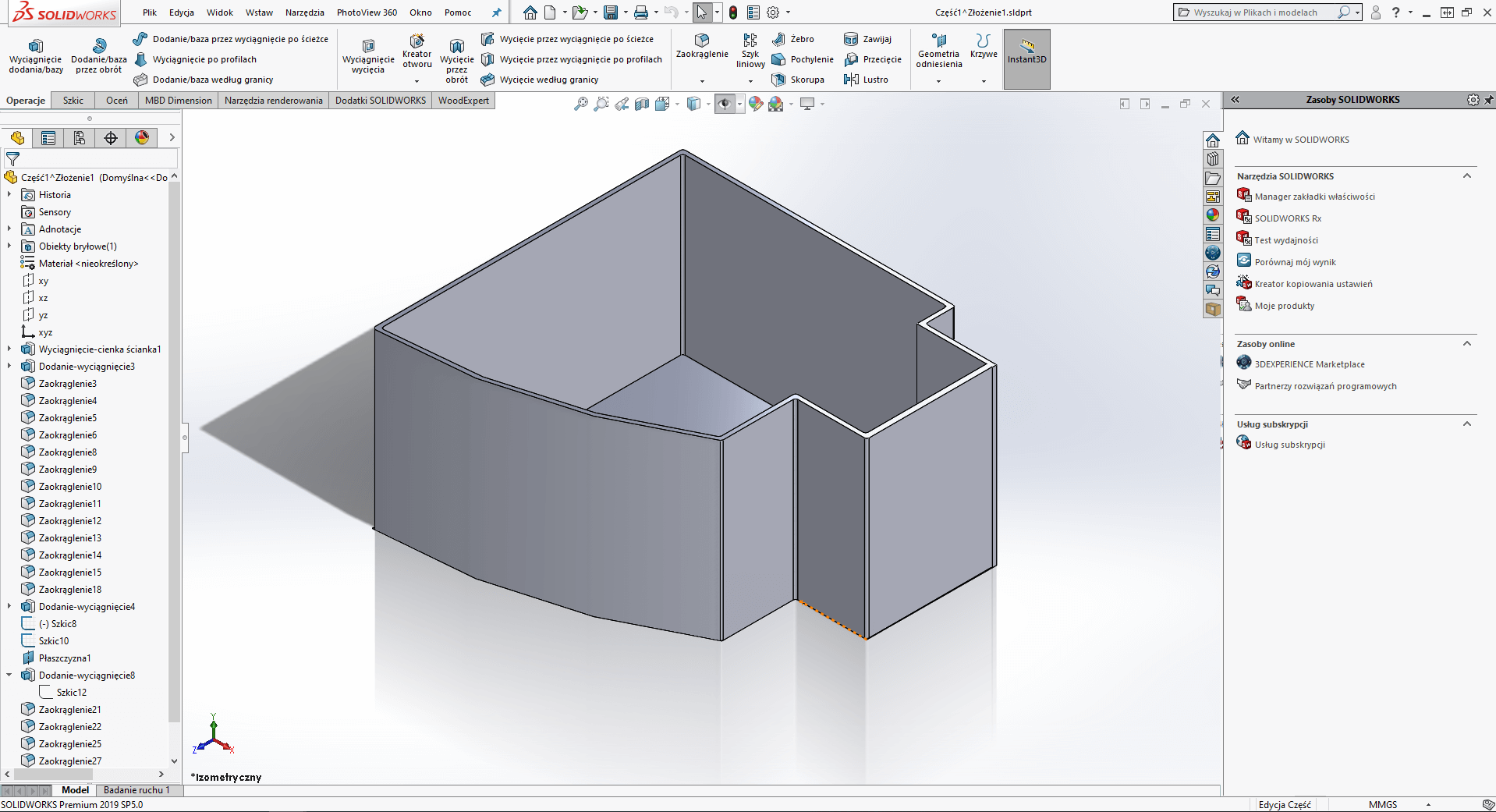

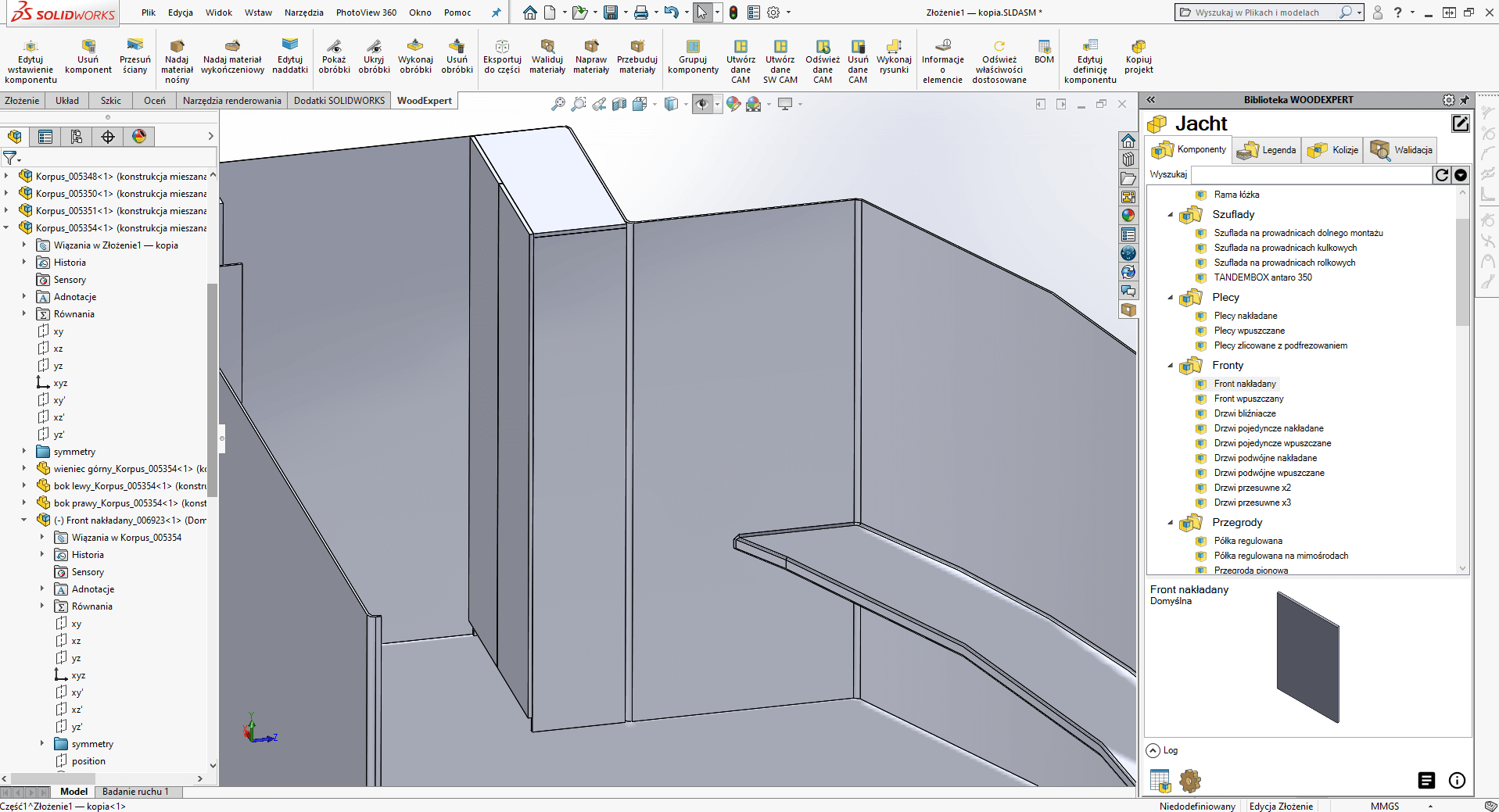

I begin my work in the software by creating a cabin, to which I will match the built-in furniture. I start from the sketch and proceed to extract the walls on its basis.

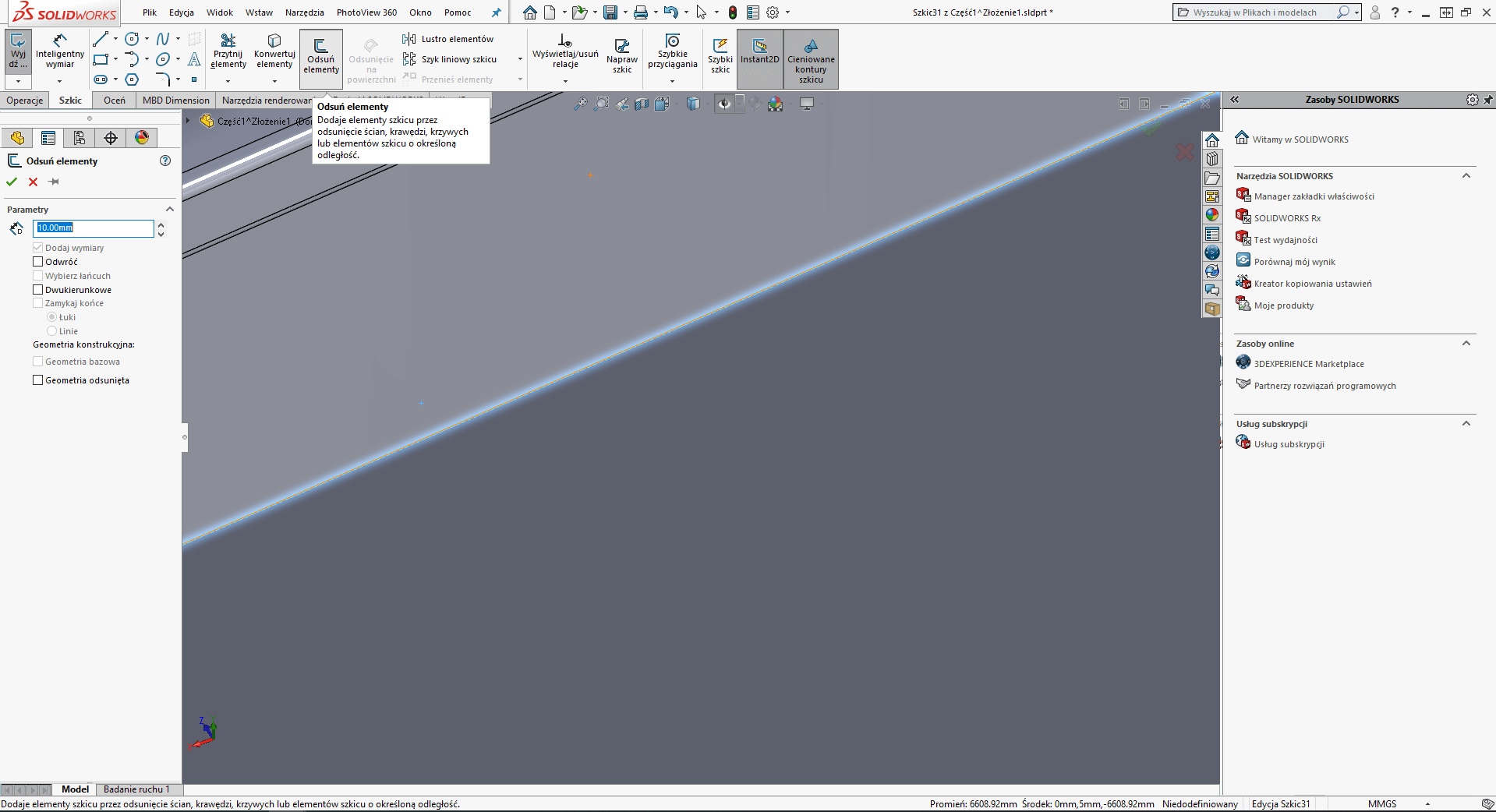

I’m moving on to creating a cabinetry. The first element will be the countertop along the length of one of the walls. Using the “Offset components” command I copy the bottom wall edge and create a countertop sketch. I create a target object using the extracting operation.

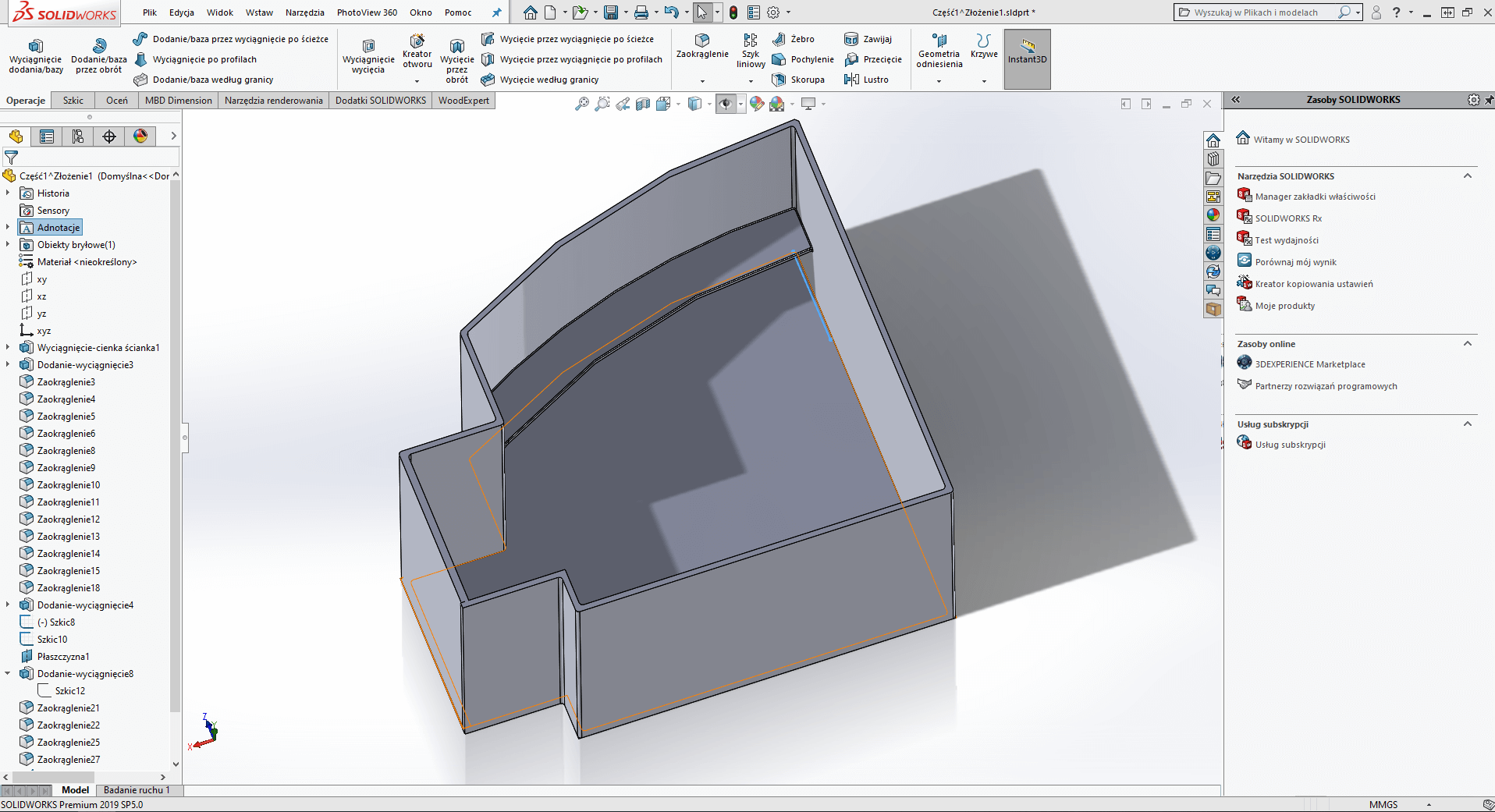

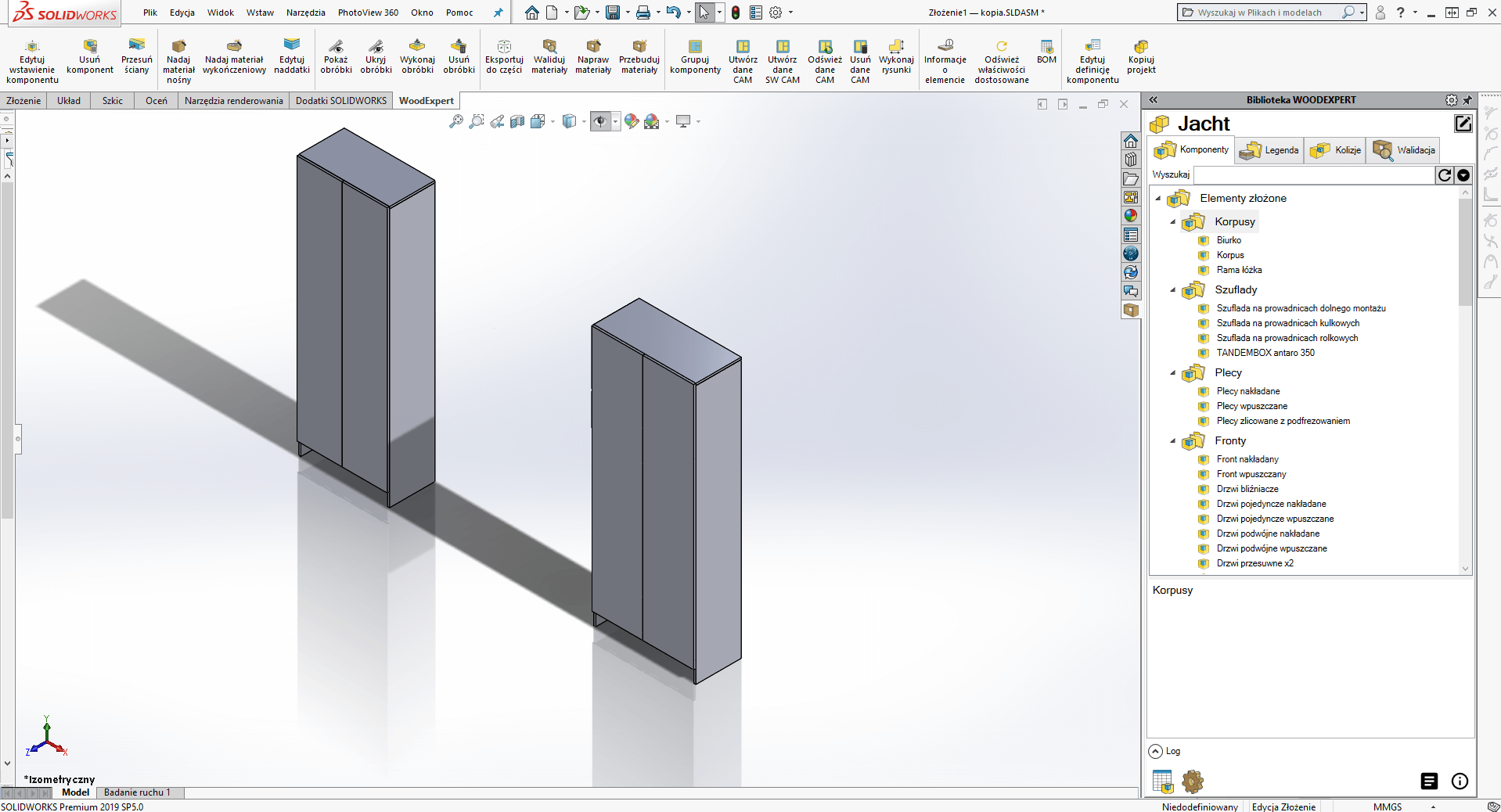

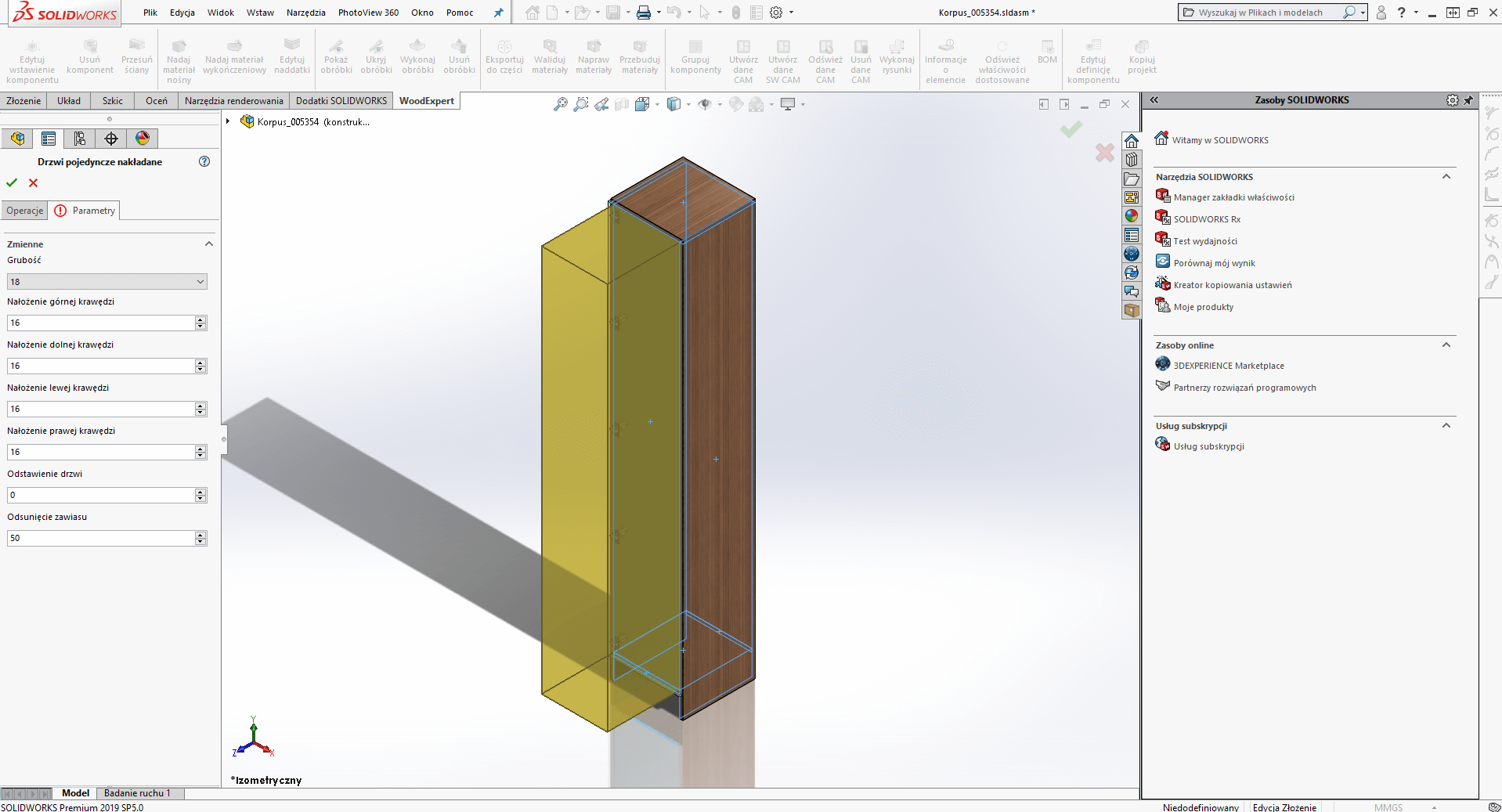

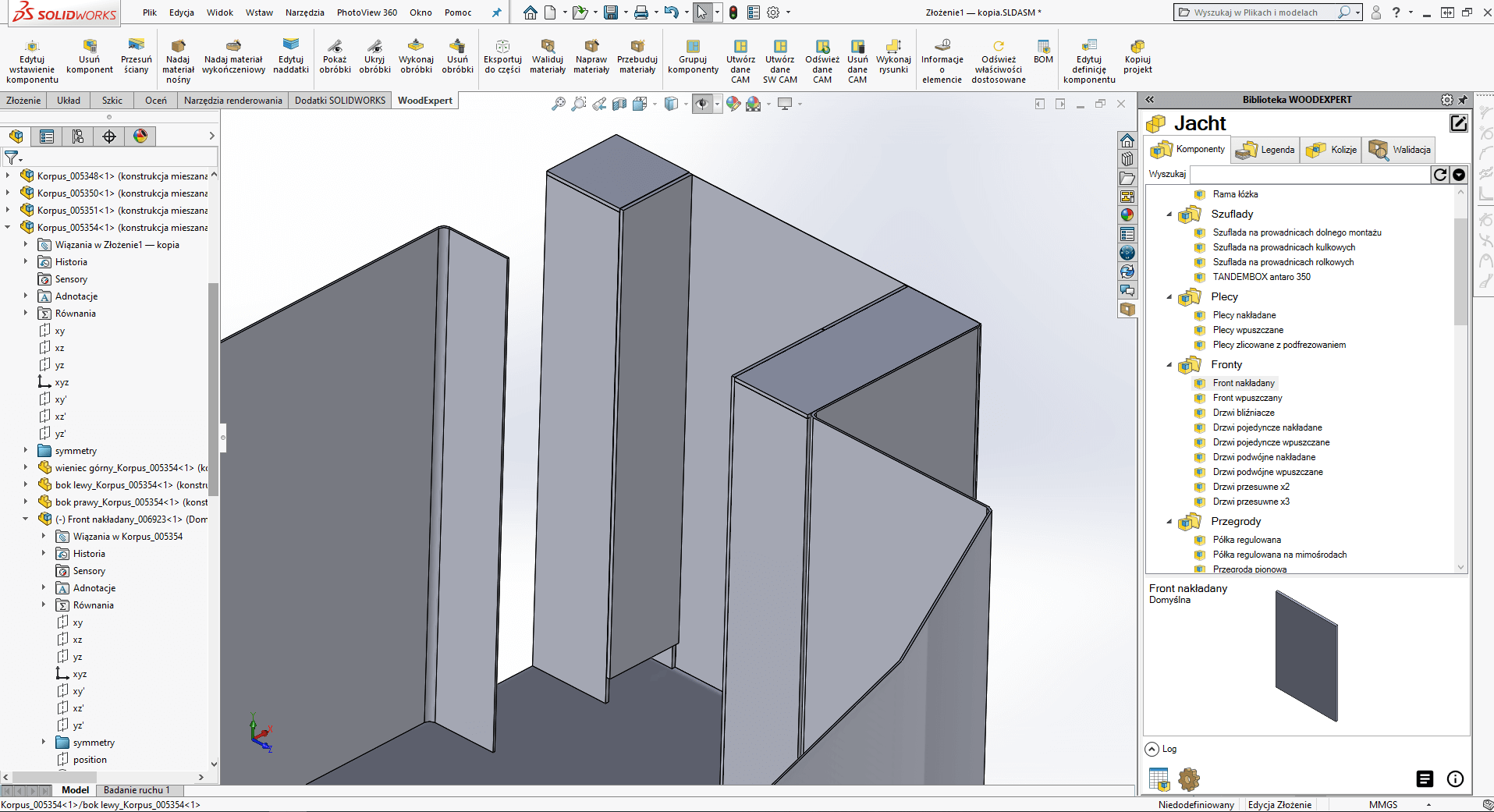

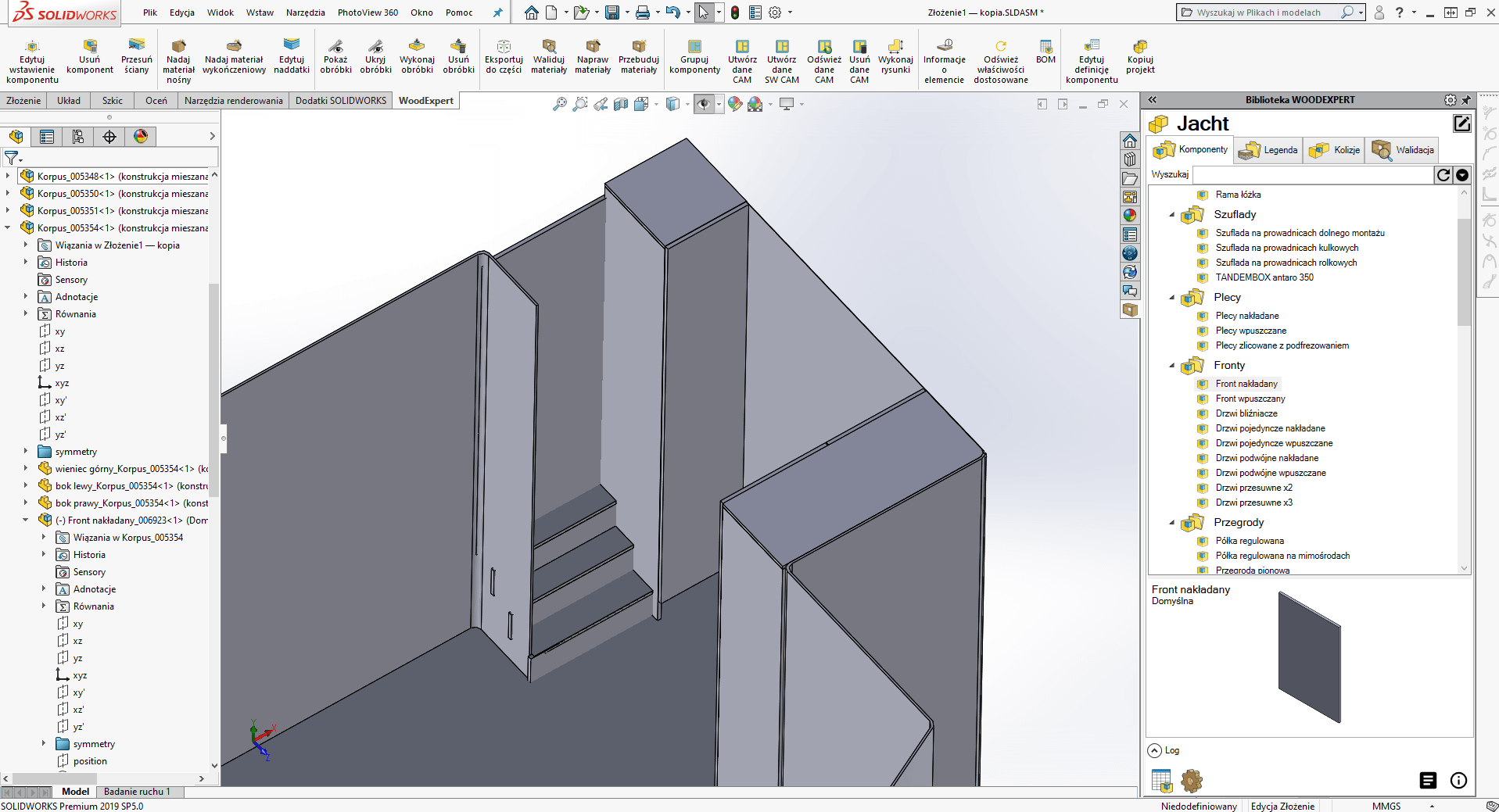

Then I proceed to design another pieces of yacht furniture. I insert two wardrobes using the components from the WOODEXPERT’s library. Furniture constructed in this fashion can be promptly saved in the library and used in other rooms or designs.

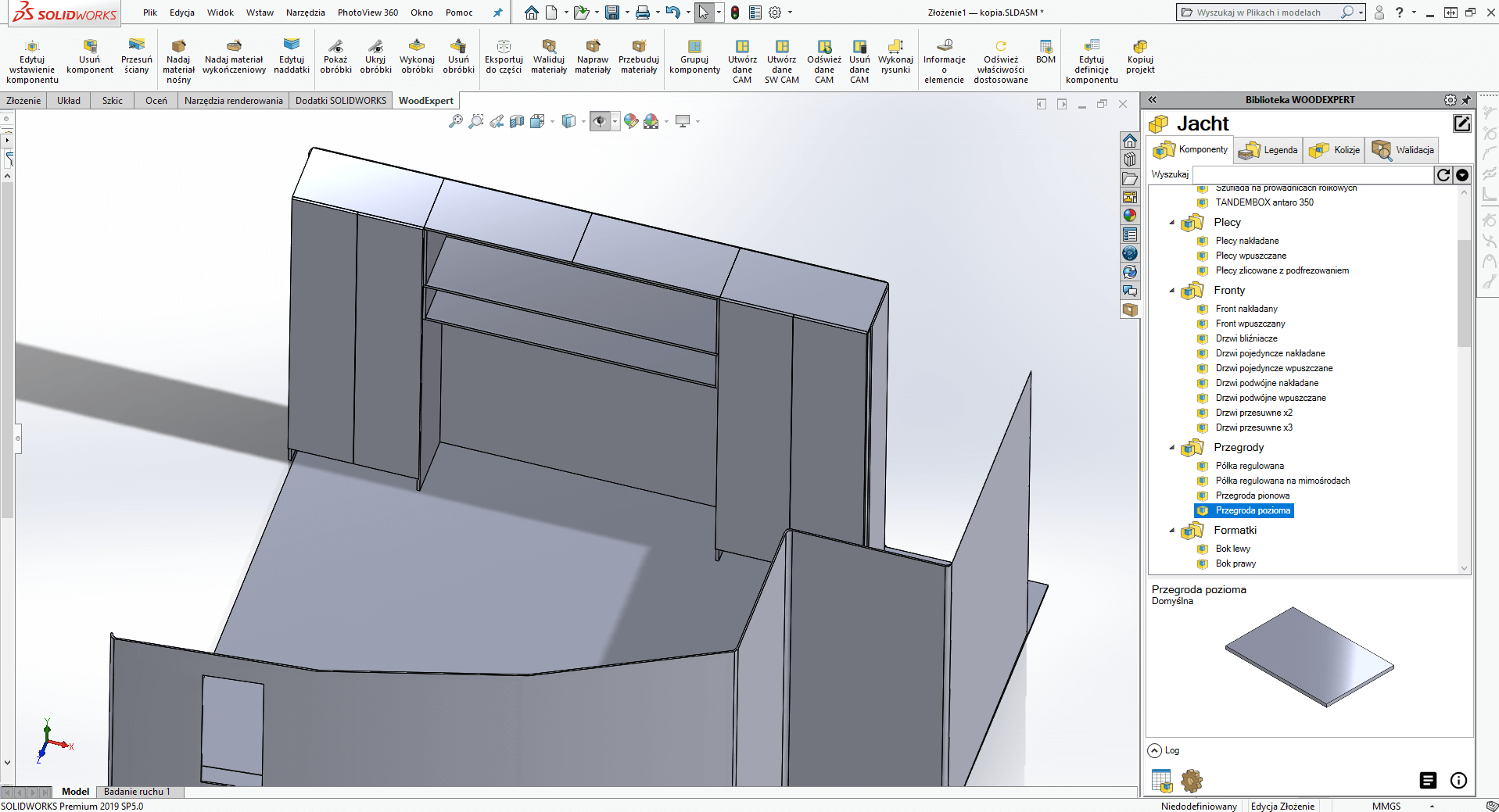

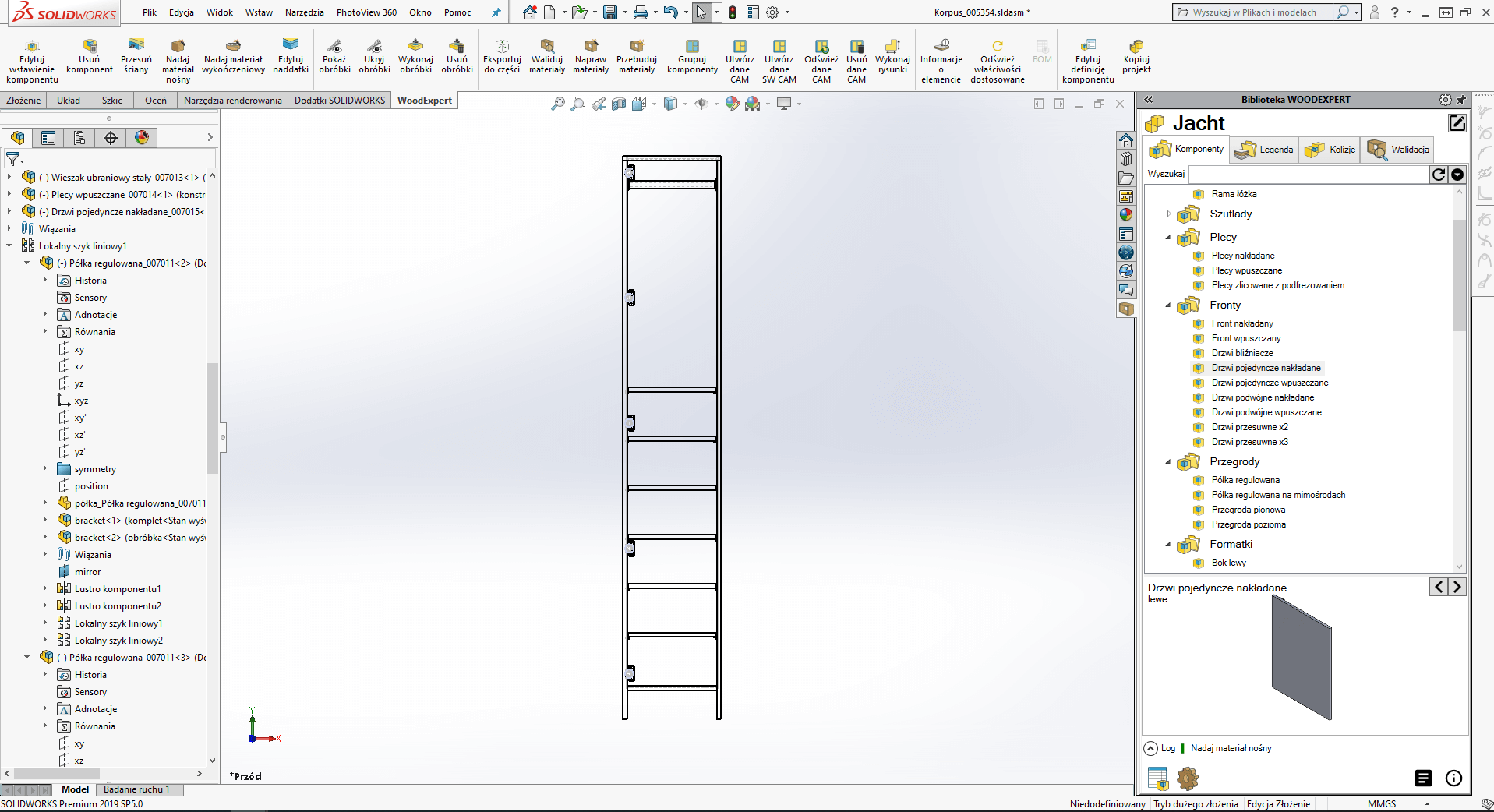

The next step is to insert shelves, partitions and thus create a single assembly, whose individual parameters we can quickly adjust.

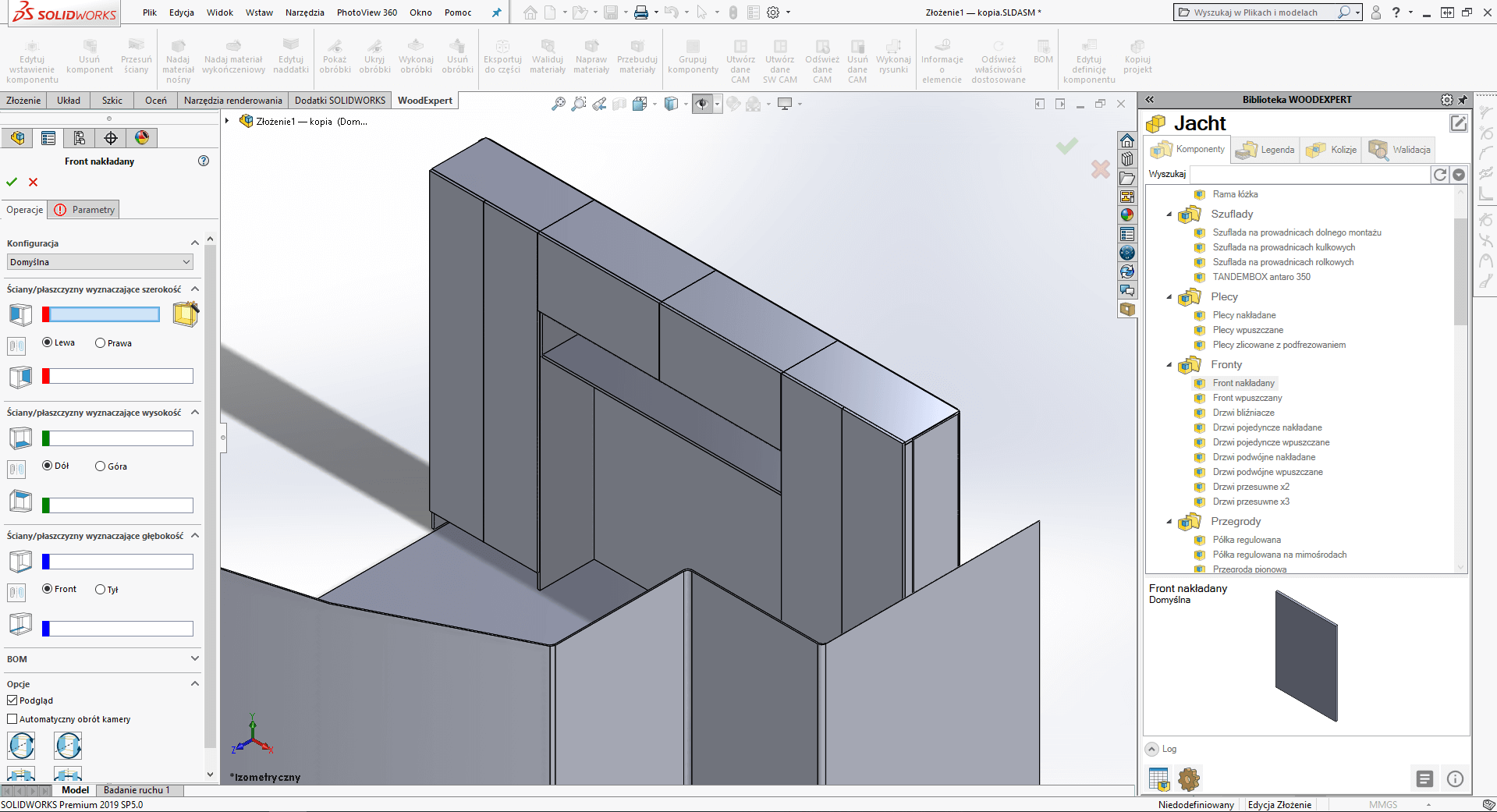

I insert additional wardrobes by adjusting their dimensions and parameters in relation to other pieces of furniture. I can change insertion parameters of the entire piece of furniture and its individual parameters at any design stage. Thanks to the integration of the WOODEXPERT furniture design software with the SOLIDWORKS environment, I can use a number of features to streamline the design process.

I can control the model by changing the display style or views at any moment.

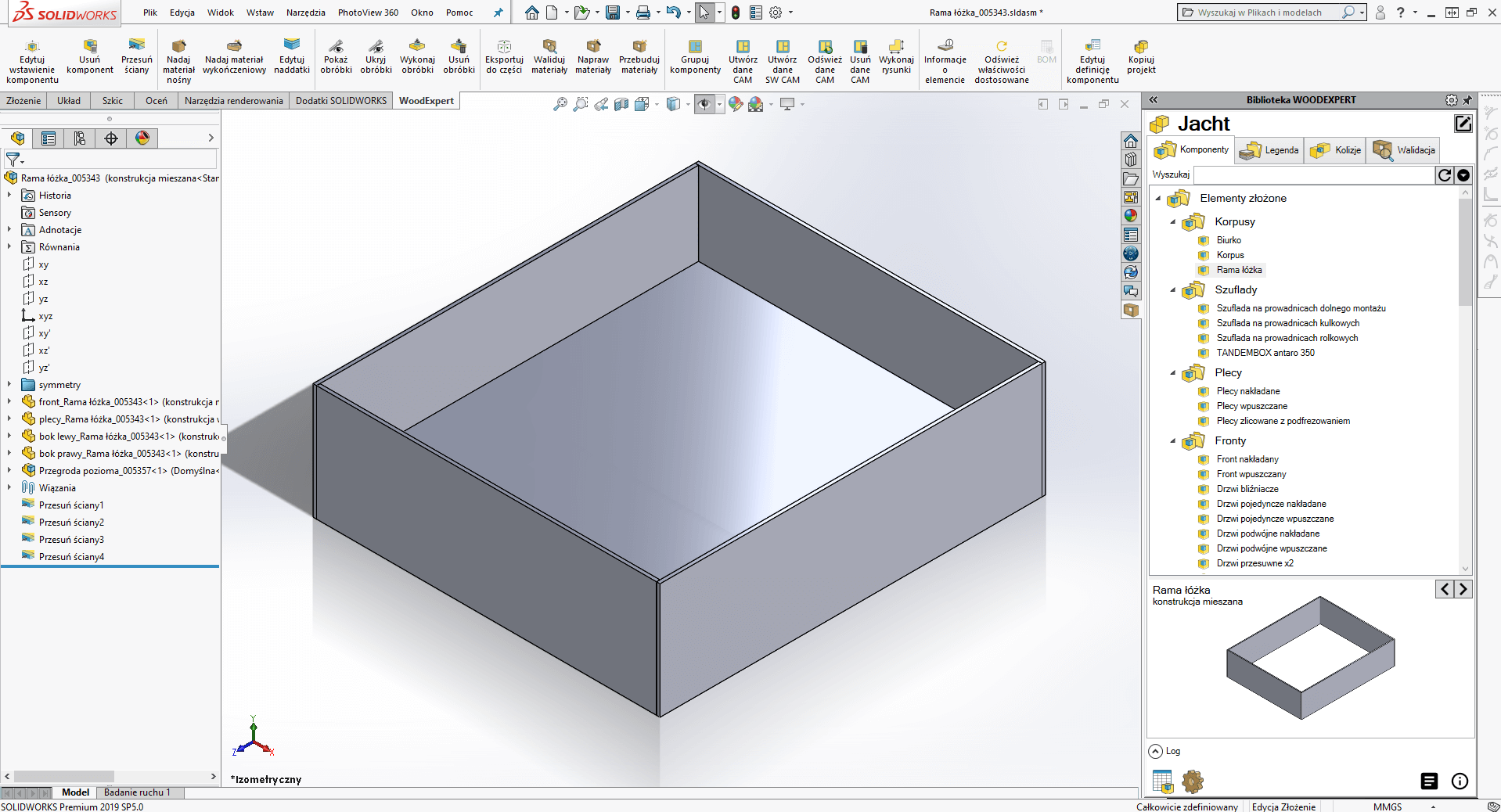

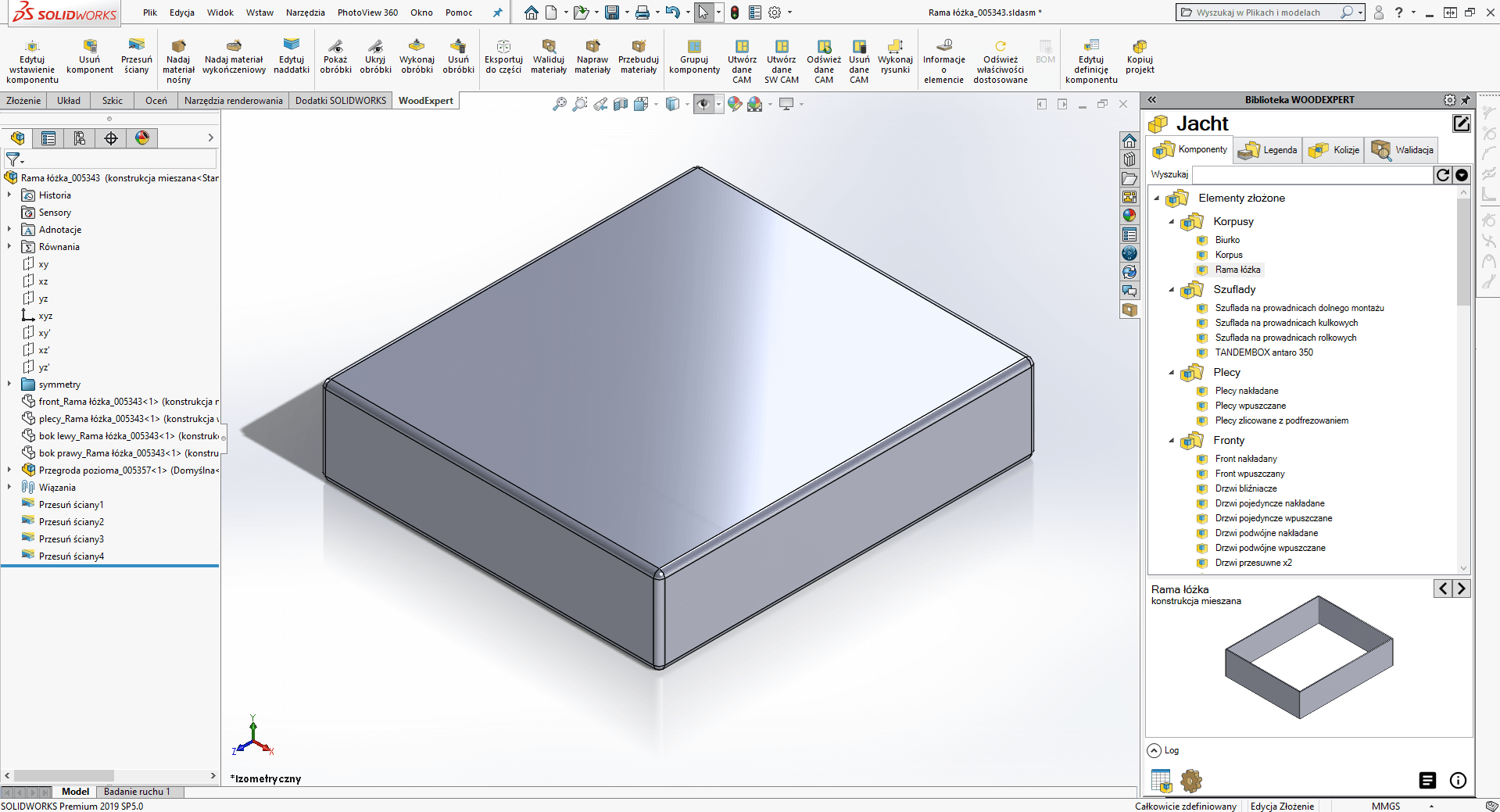

Then I insert a bed frame with a mattress — I extract them from the sketch and round the frame’s edges. With the ability to specify width parameters relative to other objects, it is inserted between cabinets in a quick manner.

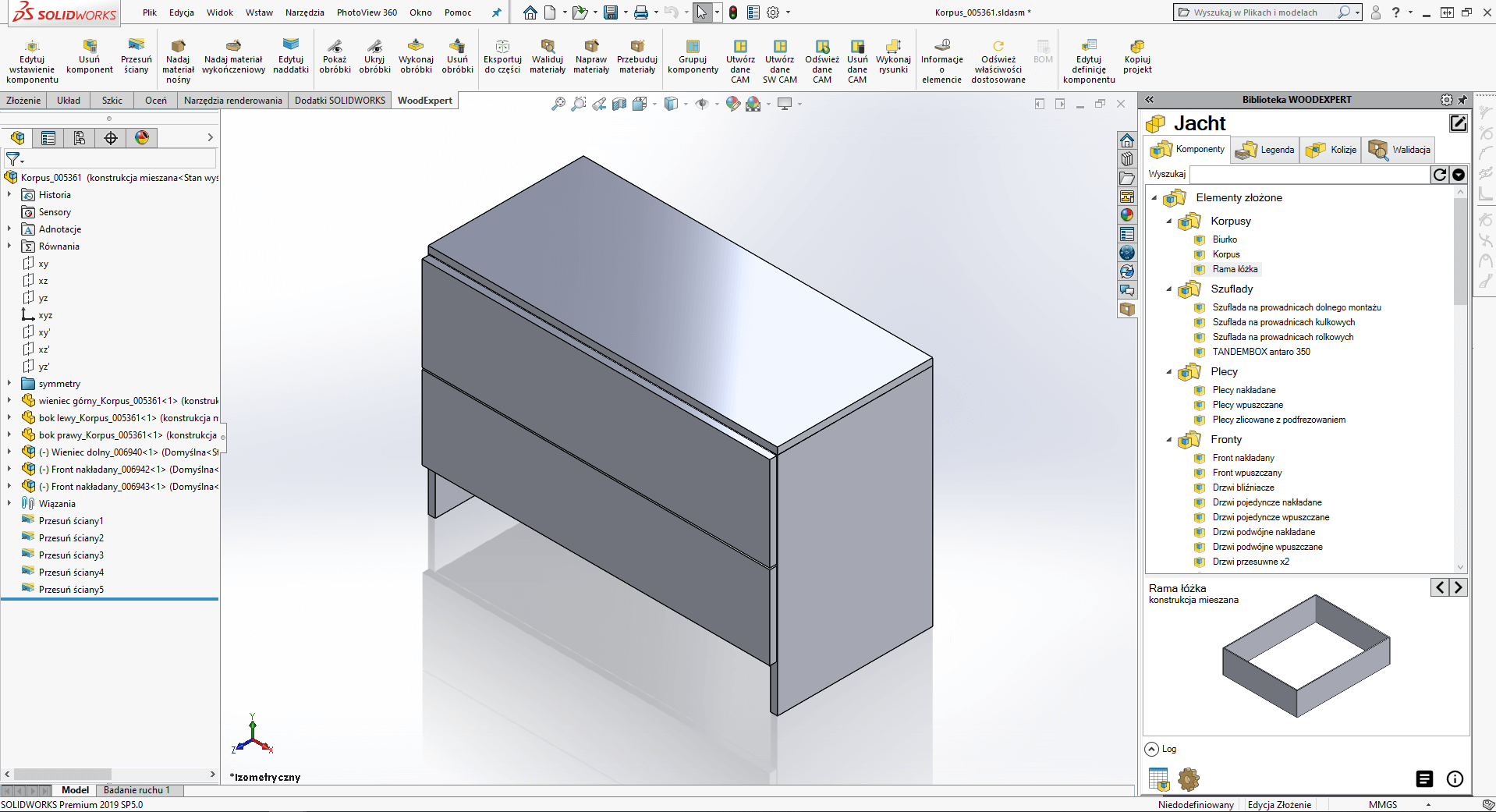

I insert a chest of drawers — its height reference is the bed frame.

WOODEXPERT allows for implementing various design solutions, that is why I quickly insert stairs and cabin door.

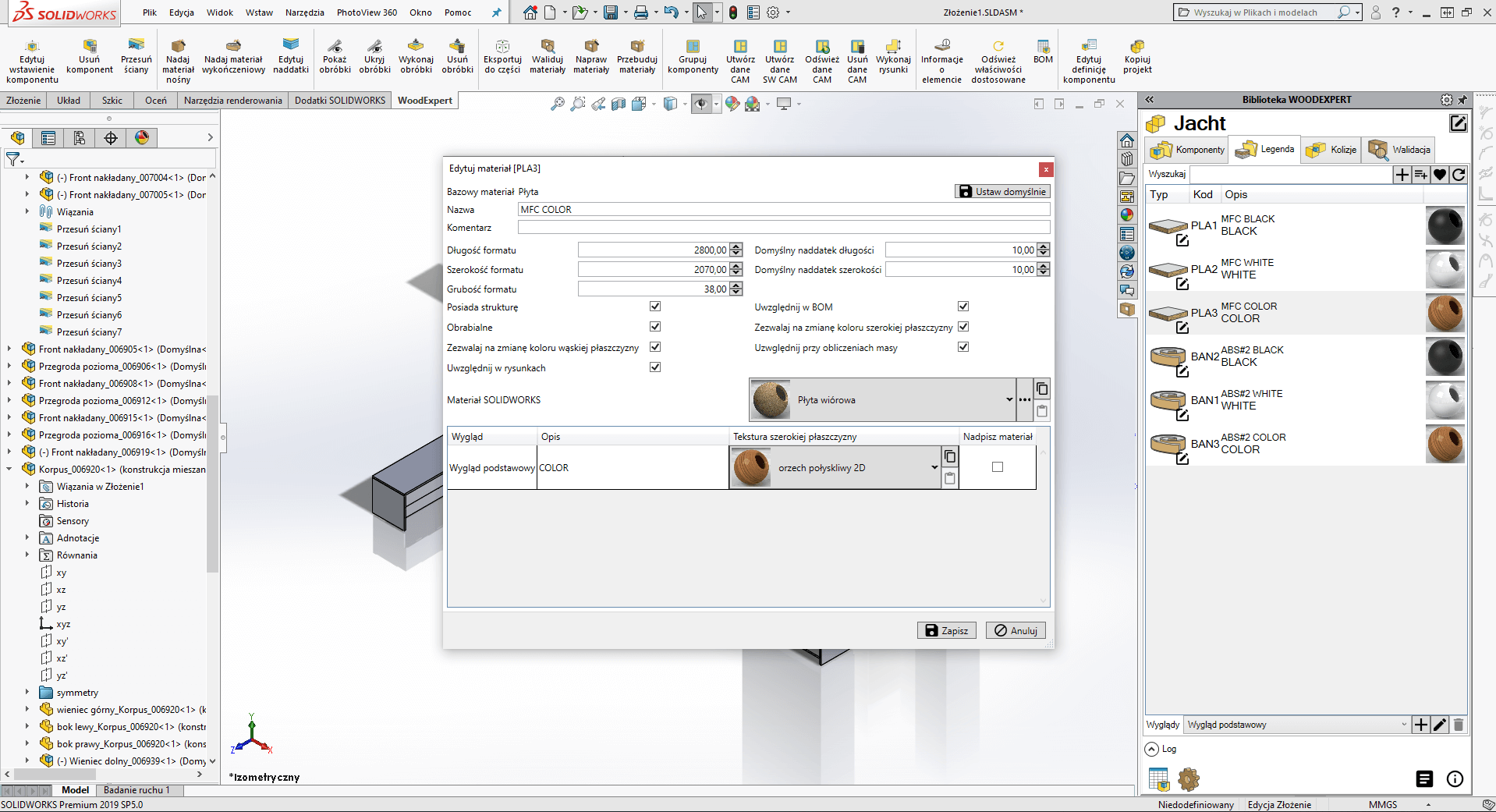

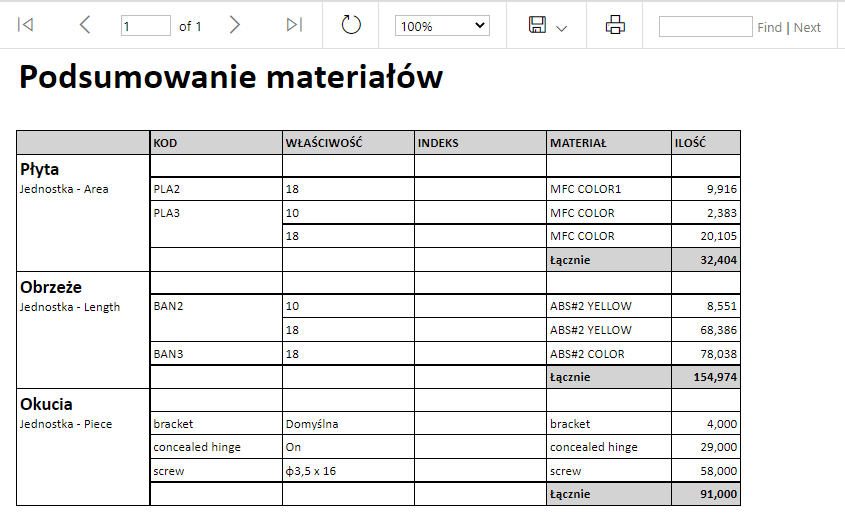

MATERIAL LEGEND

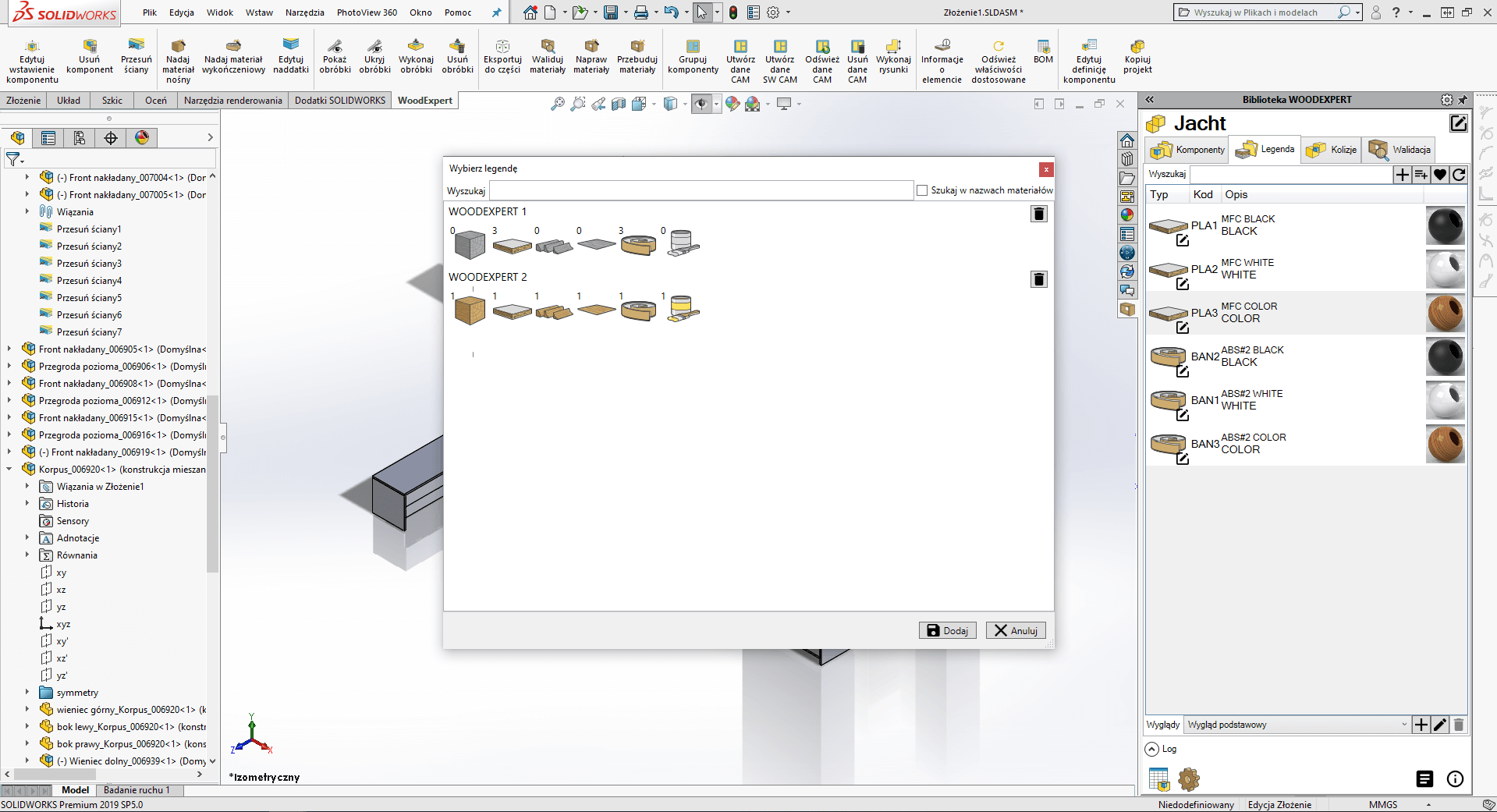

Here we have the finished furniture. The next step is to develop a material legend. In WOODEXPERT, the division by format and type of the material in question makes it possible to precisely match it to the component, and consequently to describe it in the material list and documentation.

We can save the legends by basing WOODEXPERT furniture design software on a database and add and use them in other projects and on other computers.

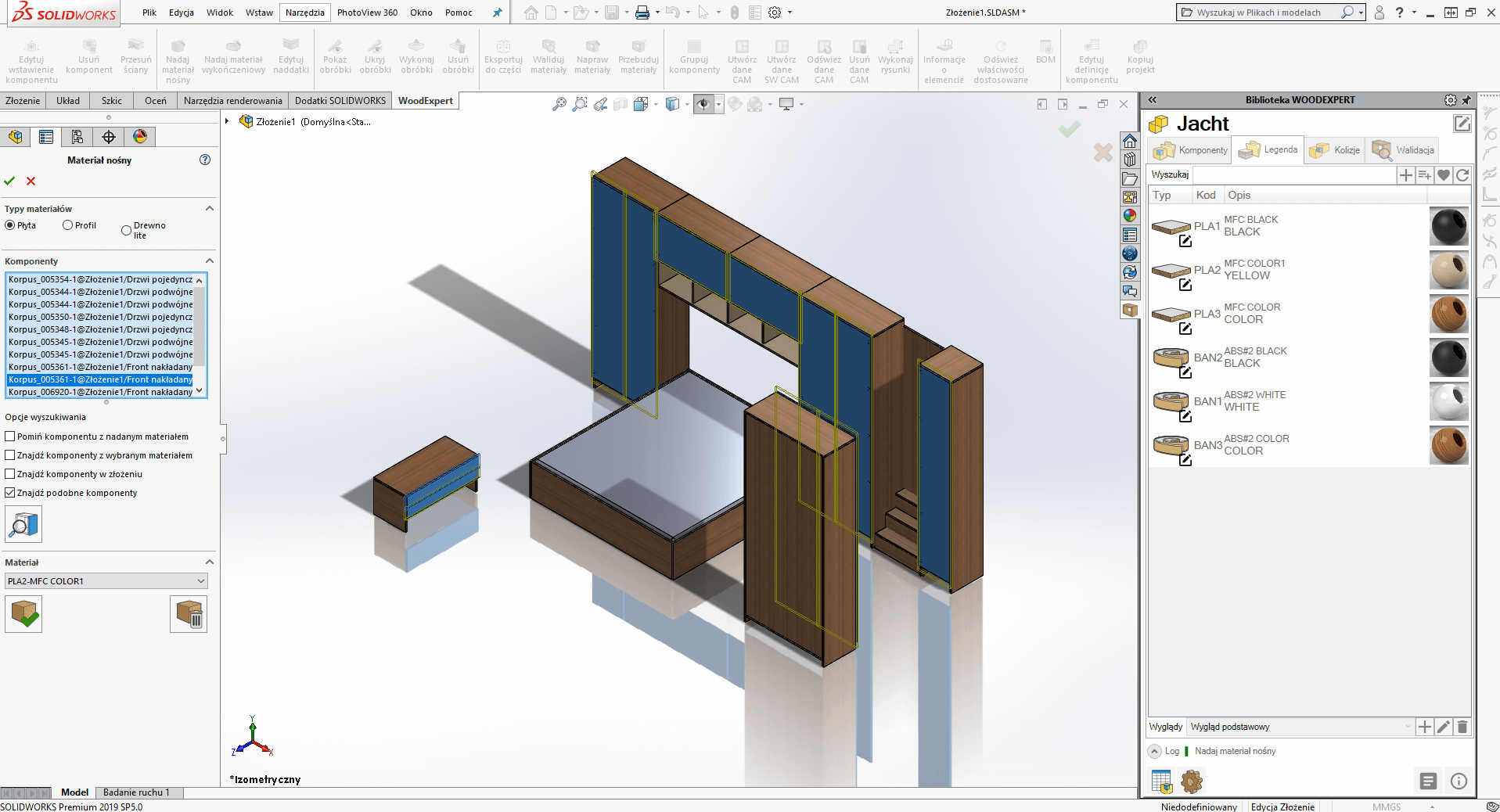

Material assignment in WOODEXPERT is easy thanks to the use of component search engine. By specifying search options, we can assign a material to a larger number of components simultaneously.

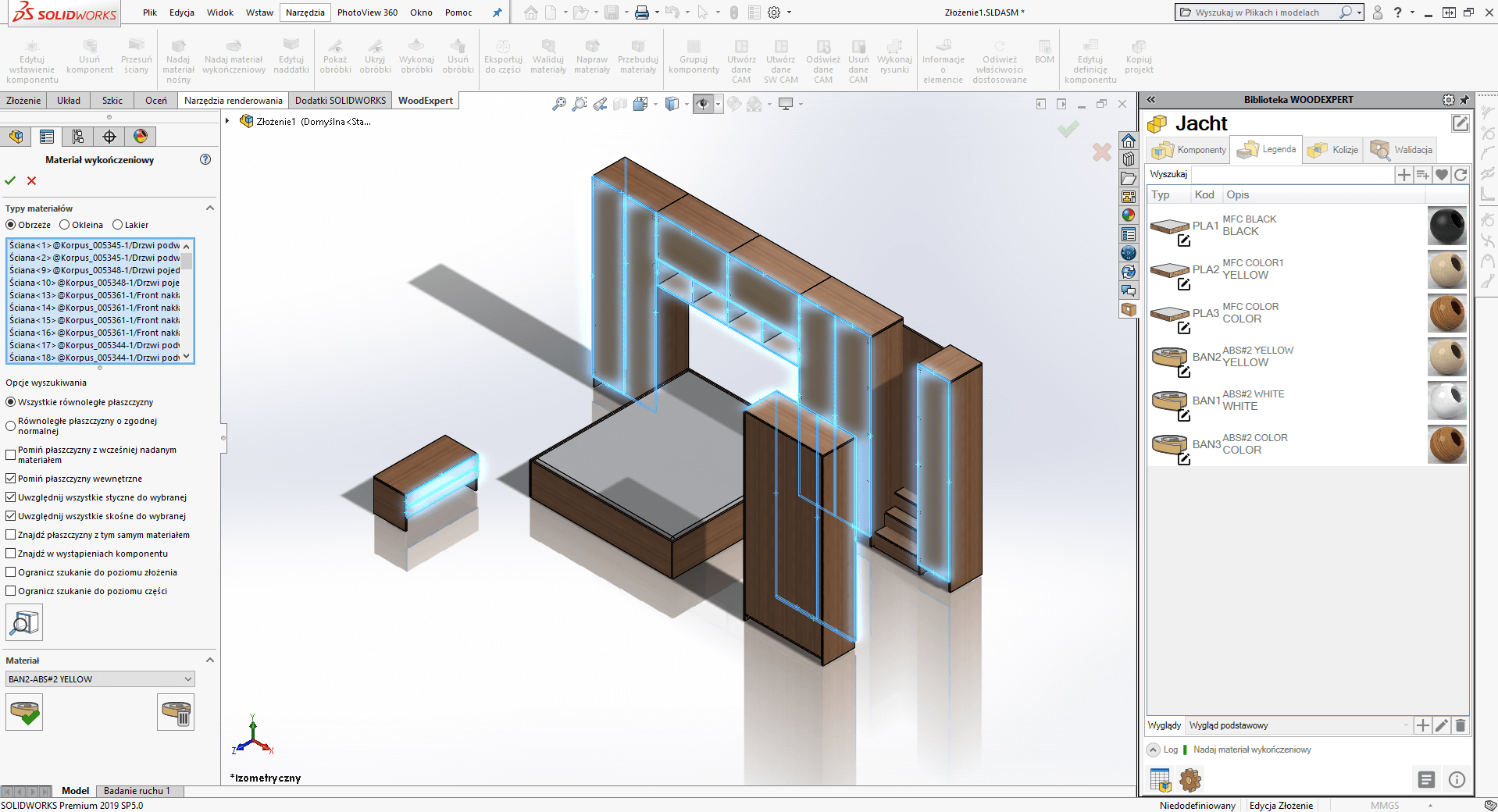

A similar process is carried out to assign finishing materials.

AUTOMATIC GENERATION OF 2D DOCUMENTATION AND BILL OF MATERIALS

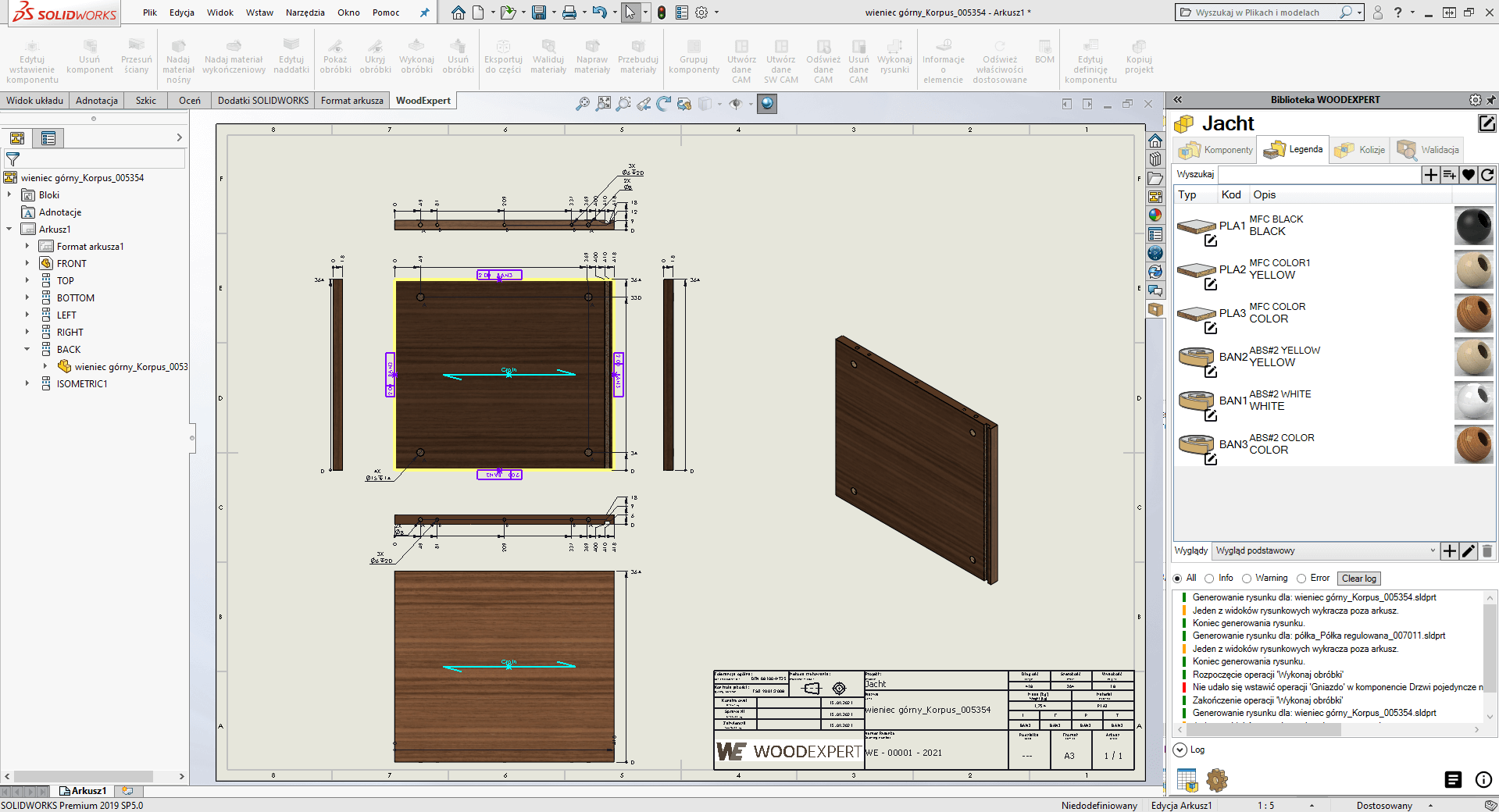

The next stage is to draw up documentation. I generate drawings and after several seconds I obtain a finished sheet with the data required for production: panel views, accurate dimensions of e.g. processing operations, or edging description.

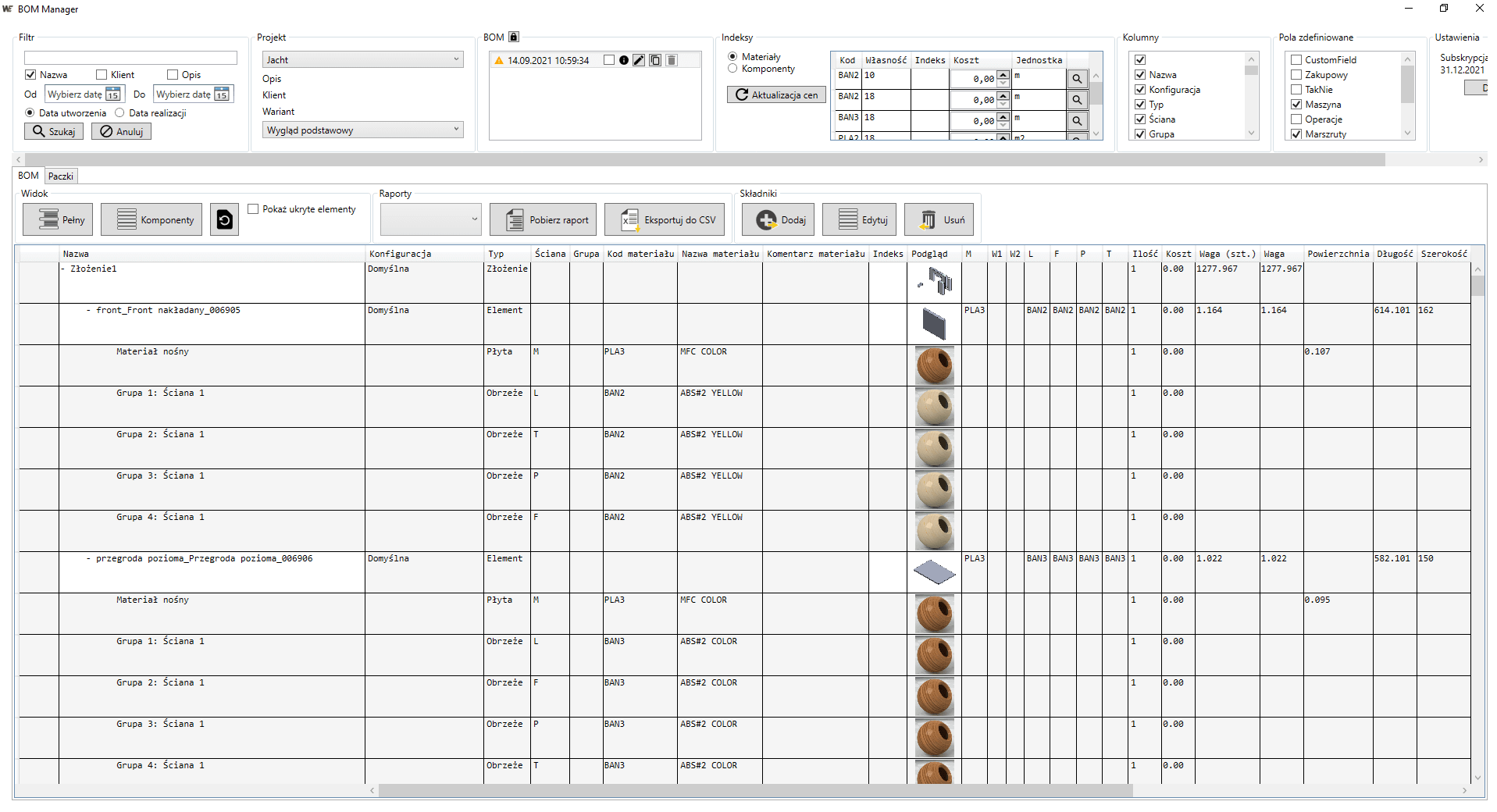

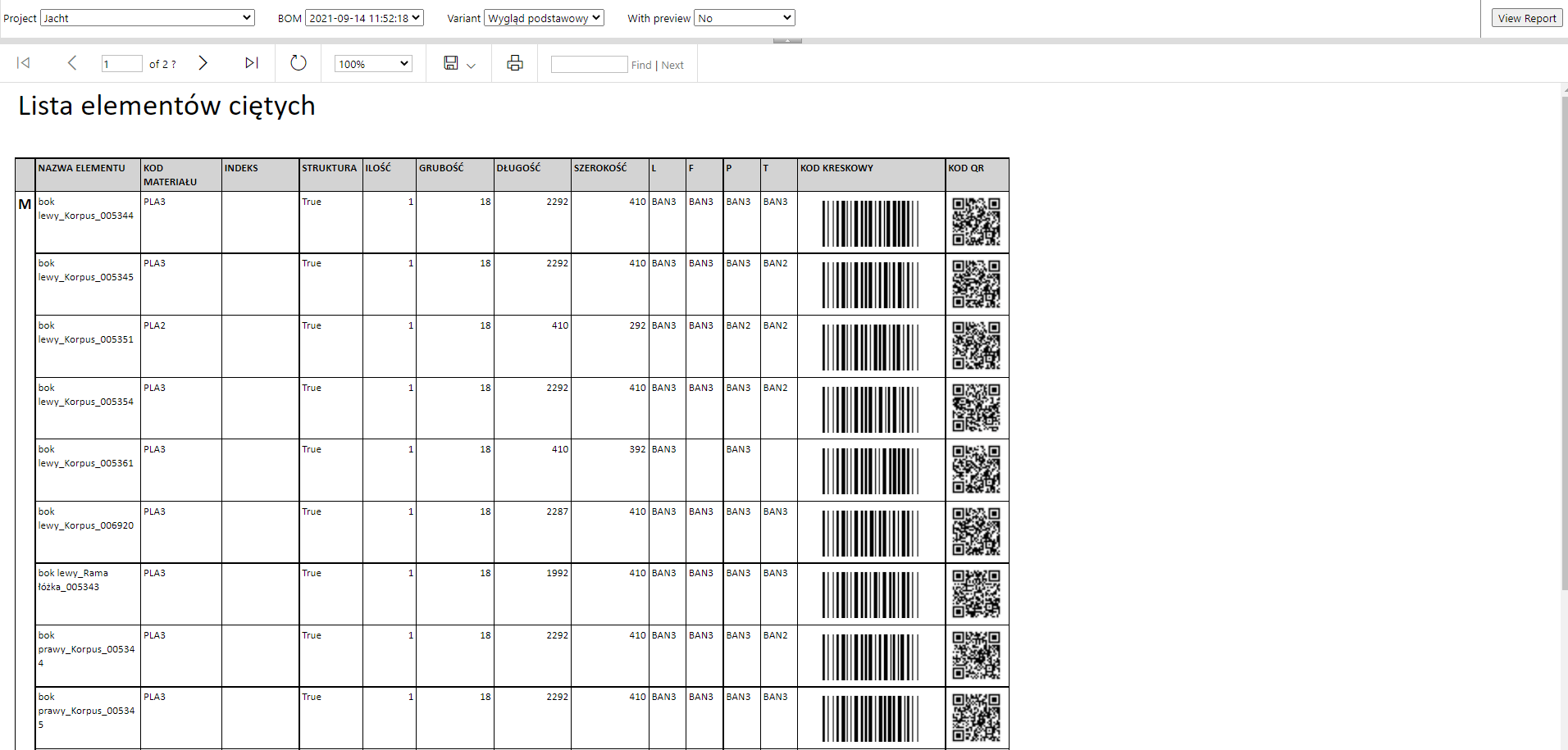

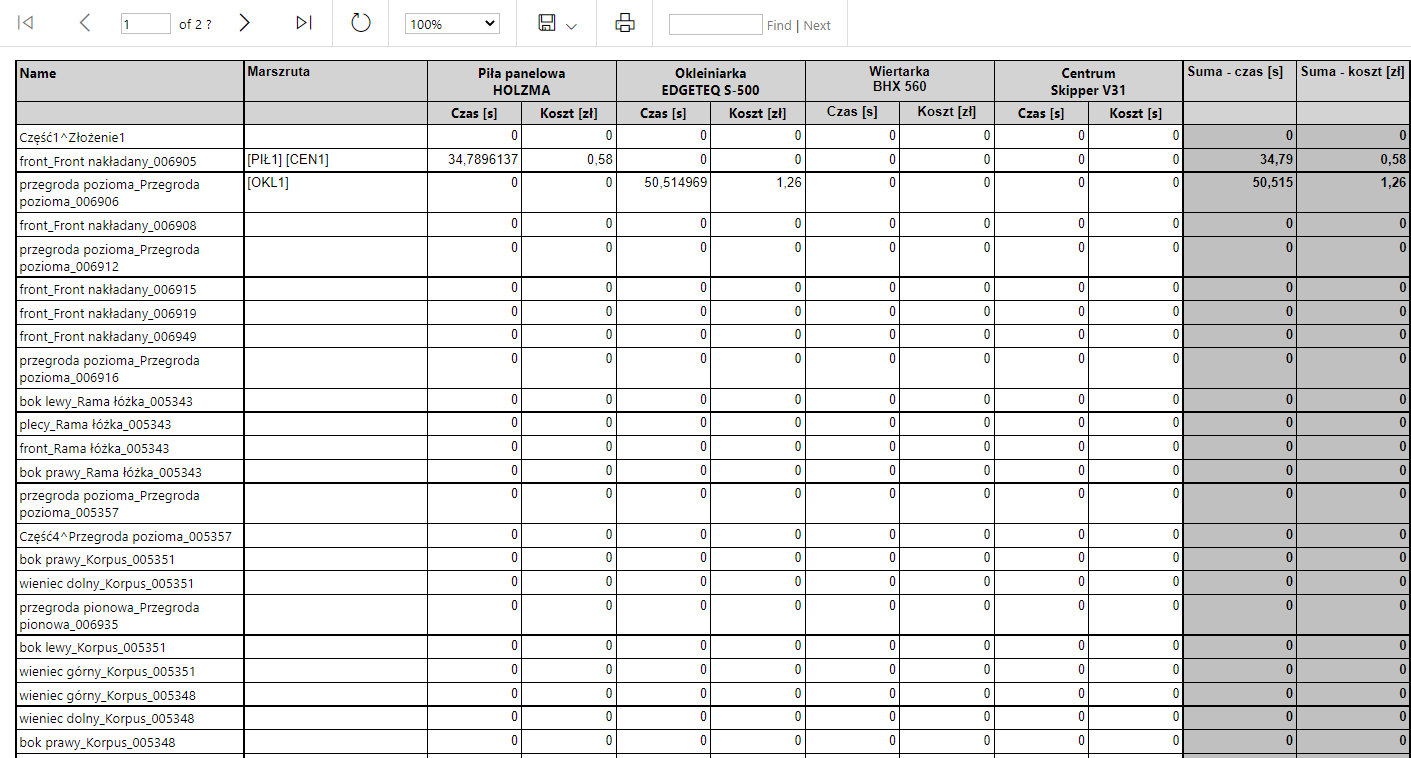

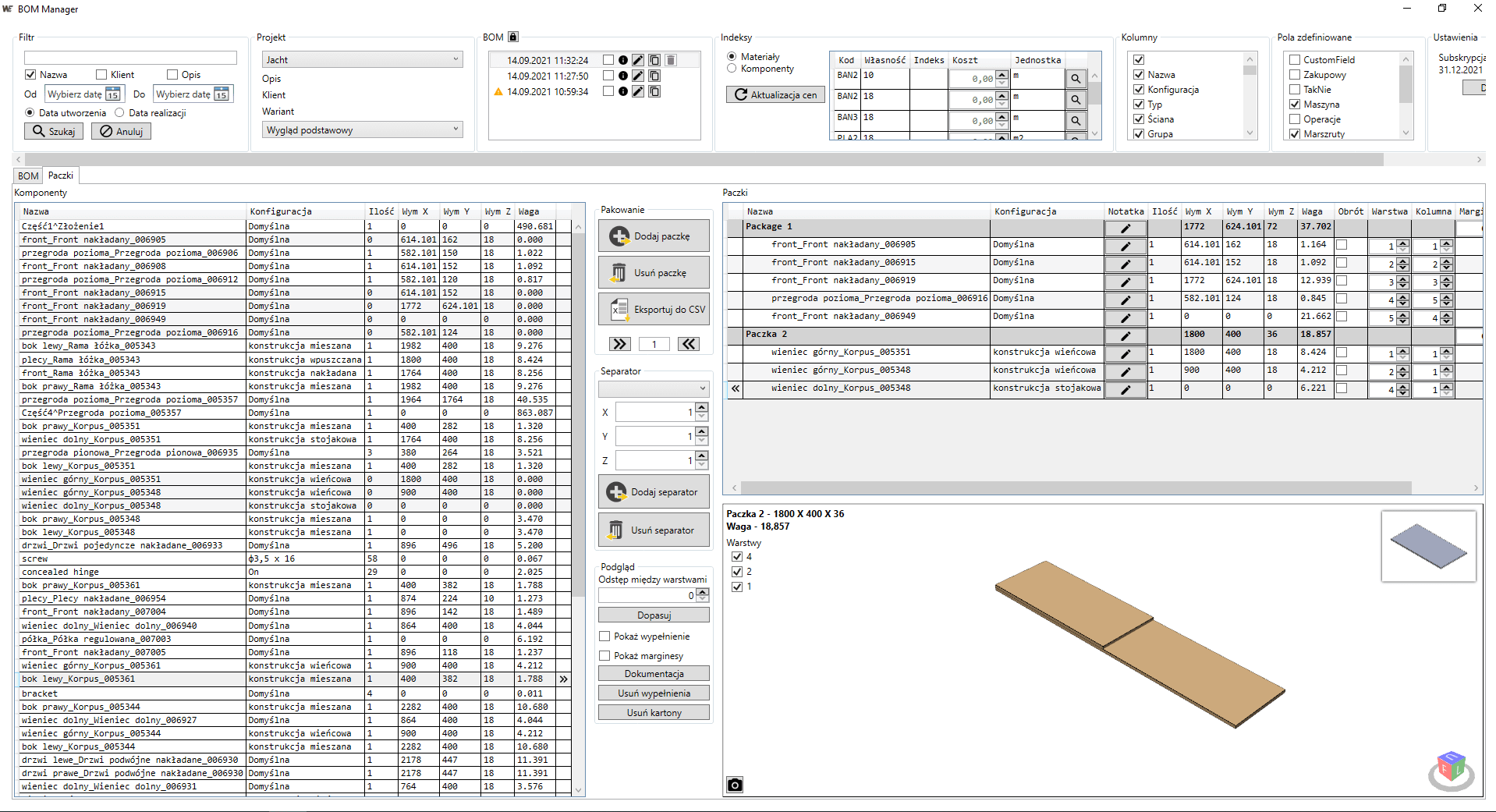

I proceed to generate the BOM. I receive a BOM with all the information on materials, hardware, quantities, detailed parameters, material gross/net dimensions, and the possibility to enter data and comments. In a generated BOM, I can also valuate furniture, retrieve production reports and, with the packing module, create packages with documentation.

I generate reports with a single click and I can send them as a link. The person receiving the report will open it in his/her browser and doesn’t have to have a WOODEXPERT licence. This makes in-company information exchange fast and smooth.

WOODEXPERT is provided with a packing feature. The layout of the parcels at the design stage makes it possible to minimize losses on material, among other things. Packing in WOODEXPERT is intuitive and allows numerous configurations to be created. It includes selecting layer arrangement, adding notes, rotating selected components, and compressing package dimensions by shifting components in columns. Furniture panel dimensions are retrieved automatically from a bill of materials.

WOODEXPERT allowed us to create an individual design with a complete set of manufacturing documentation. We encourage you to follow our blog — here you will find tips, tutorials and interesting facts from the world of furniture.

Author: Ewa Gaczorek, WOODEXPERT specialist

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…