Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

How to design a custom-made wardrobe?

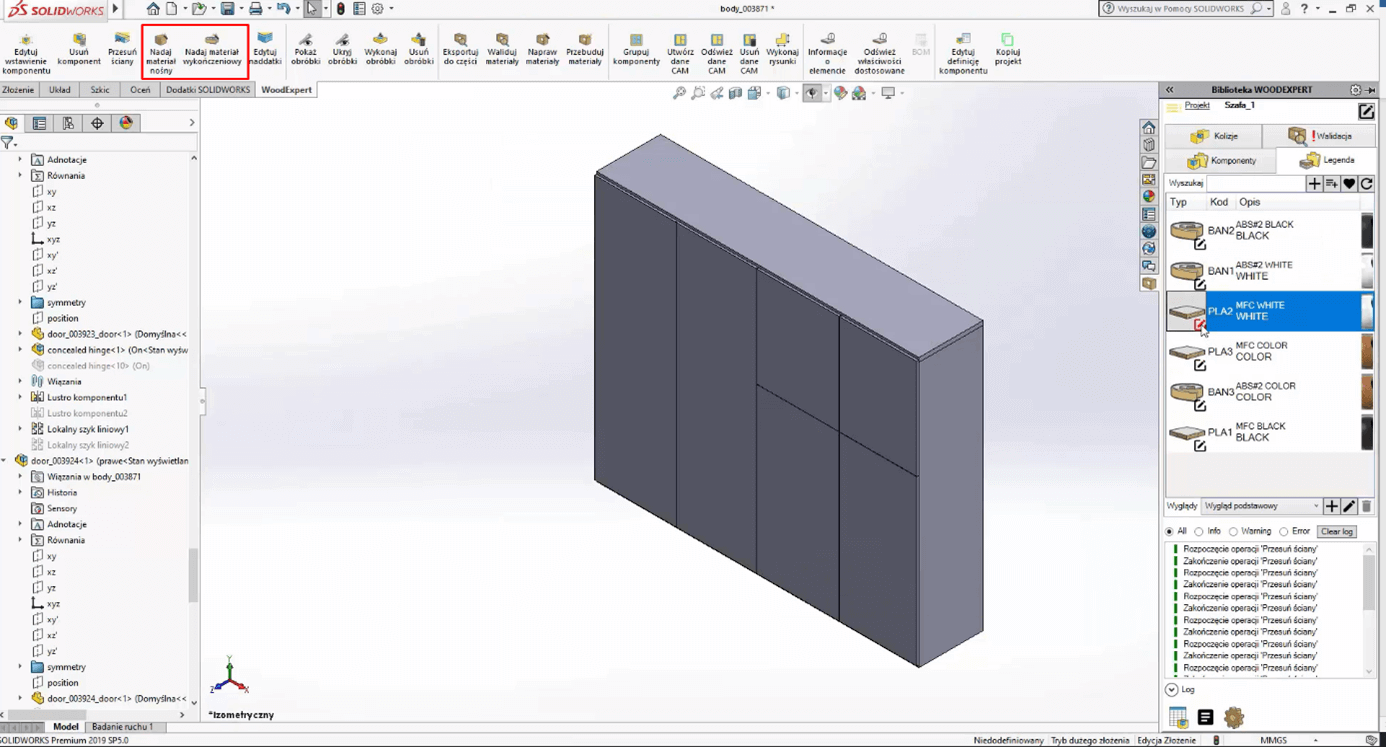

WOODEXPERT allows for creating furniture with various overall dimensions and structures — from all production stages to documentation. Due to the character of their design, custom wardrobes have numerous panel components, pieces of hardware and accessories. Without proper production support the process of their design may be time-consuming and expensive. With WOODEXPERT, you can save time and apply greater creativity and precision using its built-in modules. What does it look like in practice?

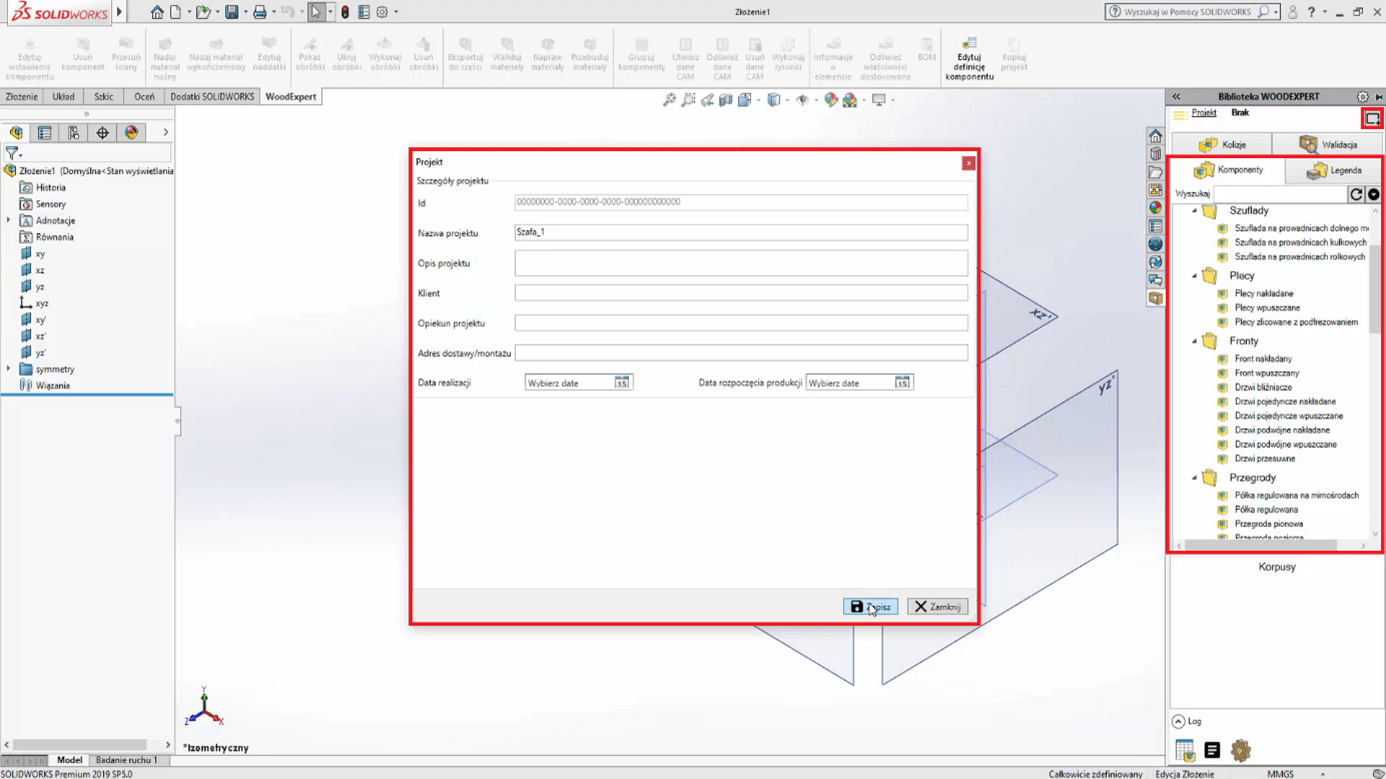

The WOODEXPERT’s library contains many folders and subfolders with all basic components to design furniture products. The software can be also used to store some part of relevant data in the shared SQL database at the initial design saving stage.

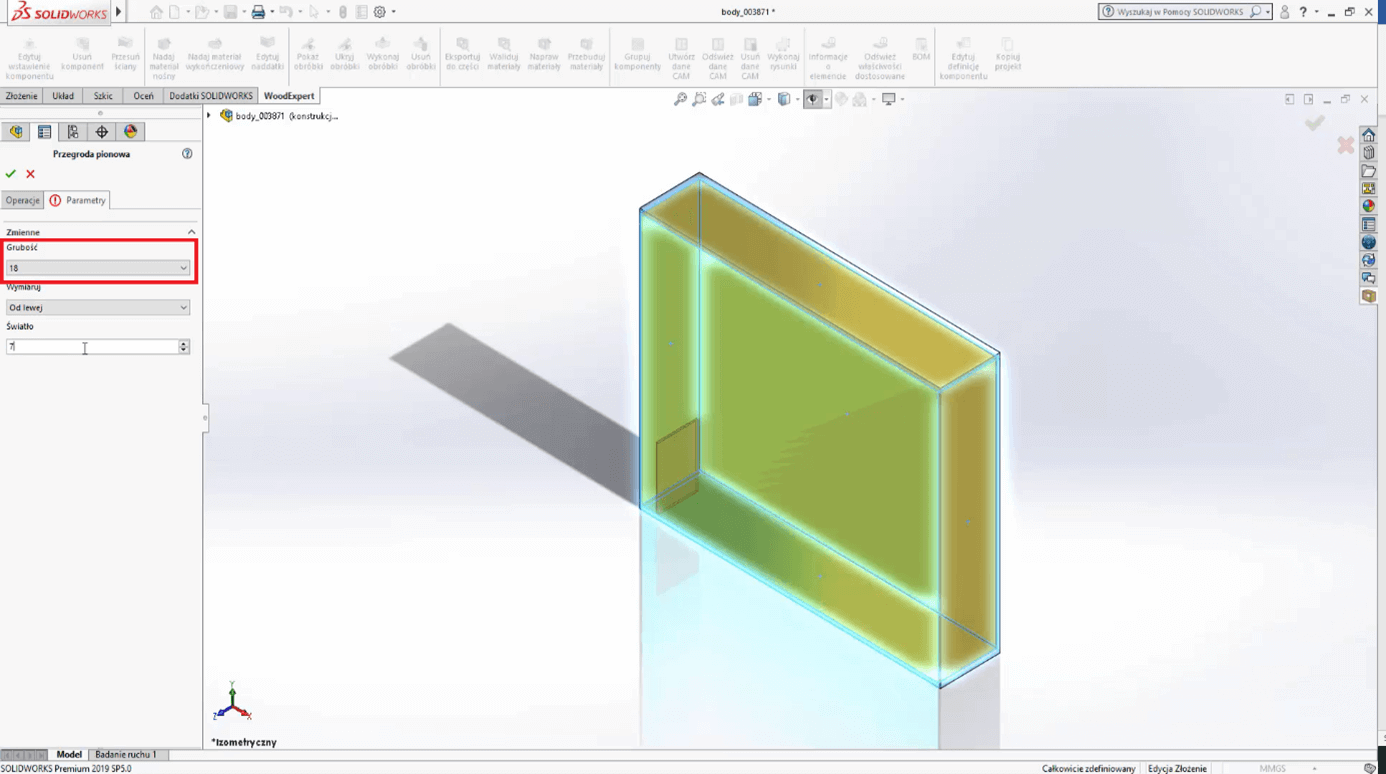

Creating a body also includes setting the panel thicknesses. The OpenGL preview ensures observation of an inserted component — that way you are sure that the parameters you entered are correct and, if required, you can change them. Additional components can be quickly inserted in relation to the body using the “Find walls” operation.

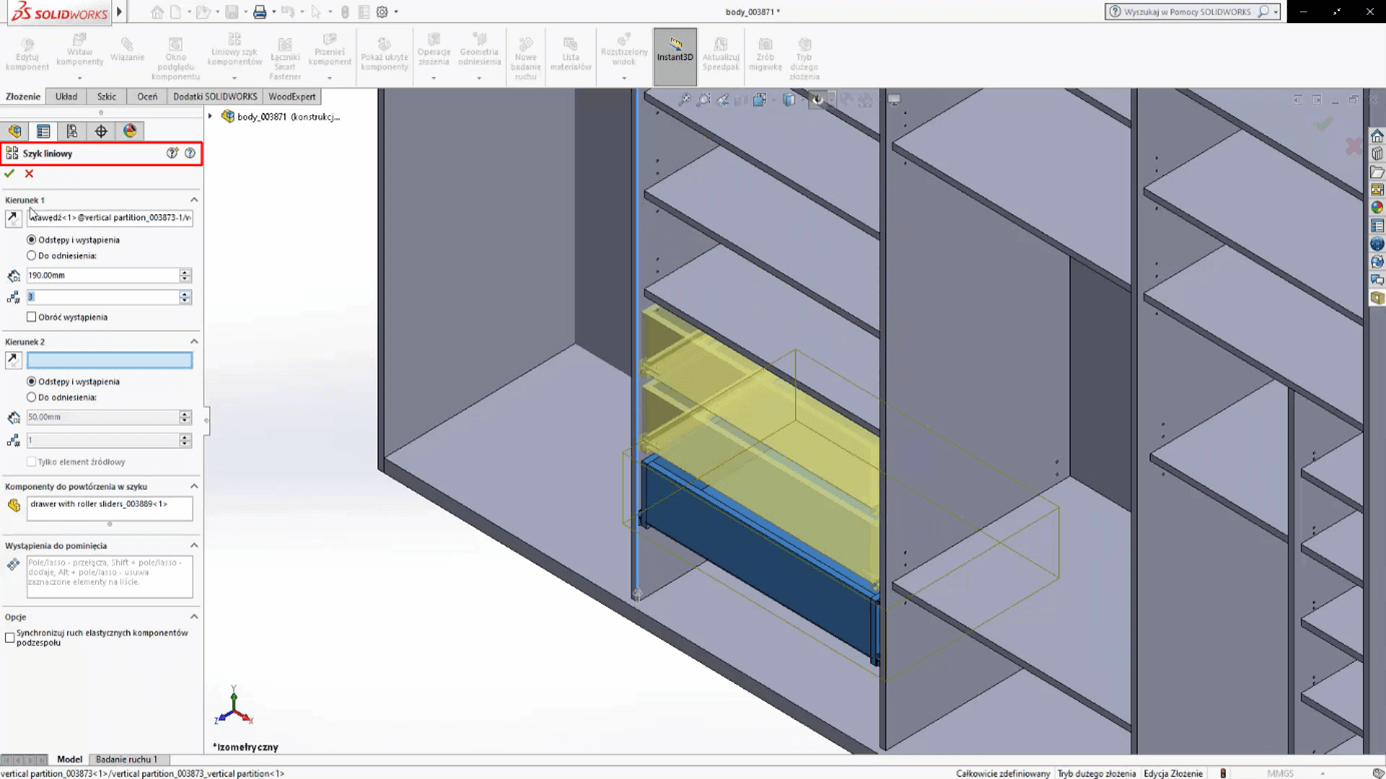

The linear sequence insertion method for shelves and drawers with a ready-to-use set of guides and screws reduces your work time. All components have predefined parameters that can be adjusted to your needs and design requirements.

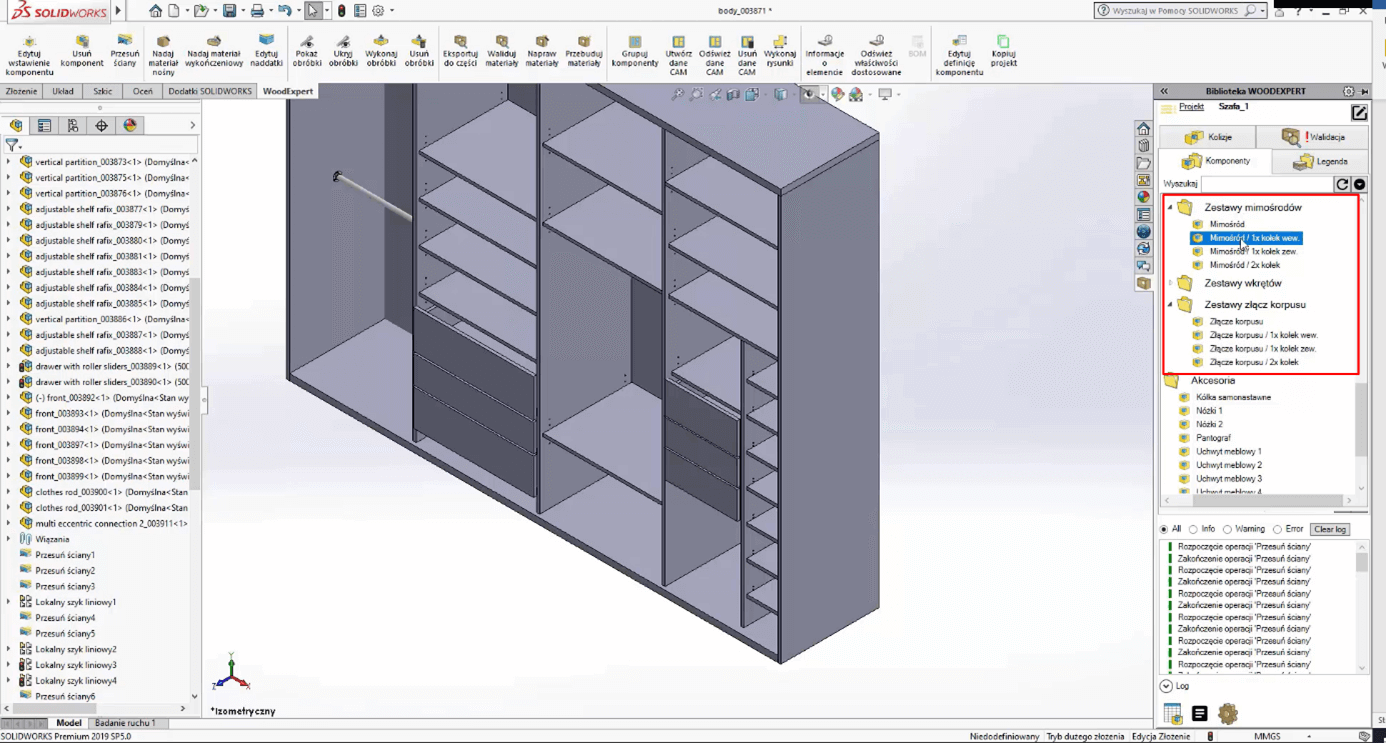

WOODEXPERT provides wide selection of fastener sets. Their quantity and instances can be defined.

While working in the project, I can change the parameters of the entire assembly model, while taking into account changes in parts and changes in the parameters of individual parts, such as the placement of shelves, their dimensions, etc. A wide selection of materials, the ability to define and save in the database correlates with the process of assigning them. In WOODEXPERT, it is specifically divided into support and finishing materials.

In WOODEXPERT, you can check the collisions of your wardrobe. As a result you avoid errors during production.

The documentation development stage includes:

- 2D drawings with full dimensioning and the required production data, for instance: any number of views, dimensions (linear, dimensional chain, opening table), CAM template, veneers, edgings, generated with a single click.

- The BOM generator is a module containing any data required to produce a wardrobe. It quickly and efficiently generates data about components and their materials based on the designed furniture model.

A generated bill of materials contain all the information, e.g. on BOMs, materials, hardware, quantities, veneering details, material gross/net dimensions, and allows for entering data and comments. You can also generate reports and carry out calculations of furniture costs.

*customised wardrobe visualisations made in SOLIDWORKS Visualize

The last stage is packing. With WOODEXPERT, you can generate furniture packing documentation, including details on package dimensions and weights that can be pre-assigned and set individually according to the company requirements.

All of these elements allow the company to modernize and open to new production capabilities.

Author: Ewa Gaczorek, WOODEXPERT specialist

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…