Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

HOW TO AVOID MISTAKES WHEN DESIGNING FURNITURE?

One of the most common problems that arise during the design of new furniture is the detection of possible collisions that may occur during assembly. Although SOLIDWORKS has a function of component penetration detection, it is difficult to find it useful in the furniture industry. Why? Not every collision has to be undesirable, e.g. when an opening prepared for a confirmat is smaller than the screw thread. We have prepared an interesting solution for you.

The furniture design software – WOODEXPERT – has a function of advanced detection of processing collisions which divides them into several groups to facilitate their identification and eliminate potential manufacturing errors. The classification of collisions is as follows:

– processing operations with each other: a collision occurs when two processing operations overlap, e.g. making openings for a hinge carrier and a shelf pin;

– processing operations with non-machinable elements: a collision occurs when a processing operation is carried out on an element marked as non-machinable, e.g. a mirror and a bolt;

– non-machinable elements with each other: a collision occurs when two non-machinable elements, e.g. two confirmats, overlap;

– machinable elements with each other: a collision occurs when two machinable elements, e.g. the back entering the body, overlap;

– machinable with non-machinable elements: a collision occurs when a machinable element overlaps with a non-machinable element, e.g. a panel and a confirmat.

Thanks to the exact division, the user is able to verify at an early stage of design whether a given collision is advantageous (e.g. a board and a confirmat) or not (two intersecting confirmats). The user can thus minimise the number of possible production errors and production losses.

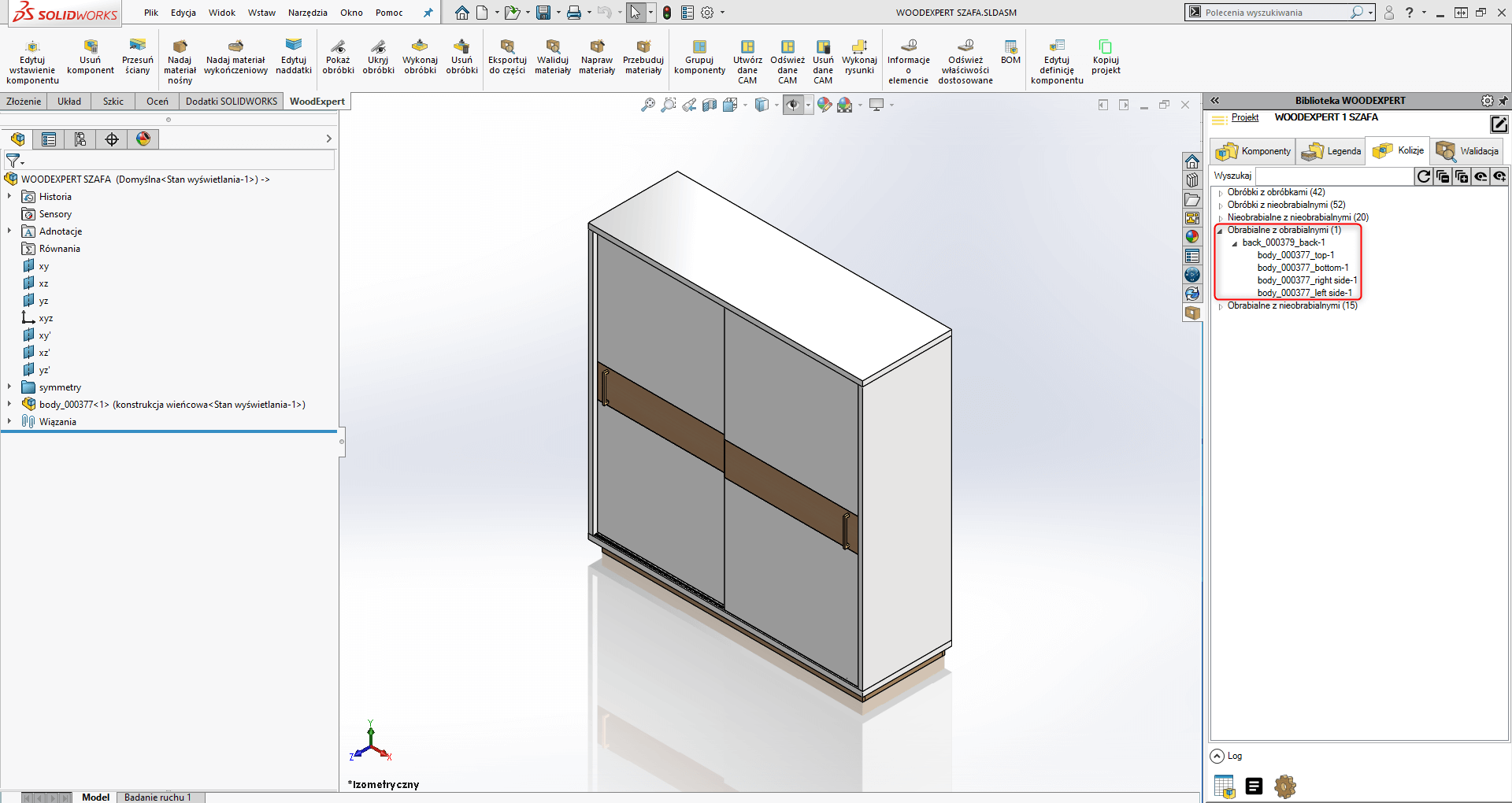

The following screenshot shows that WOODEXPERT indicates collisions occurring before processing in machinable elements:

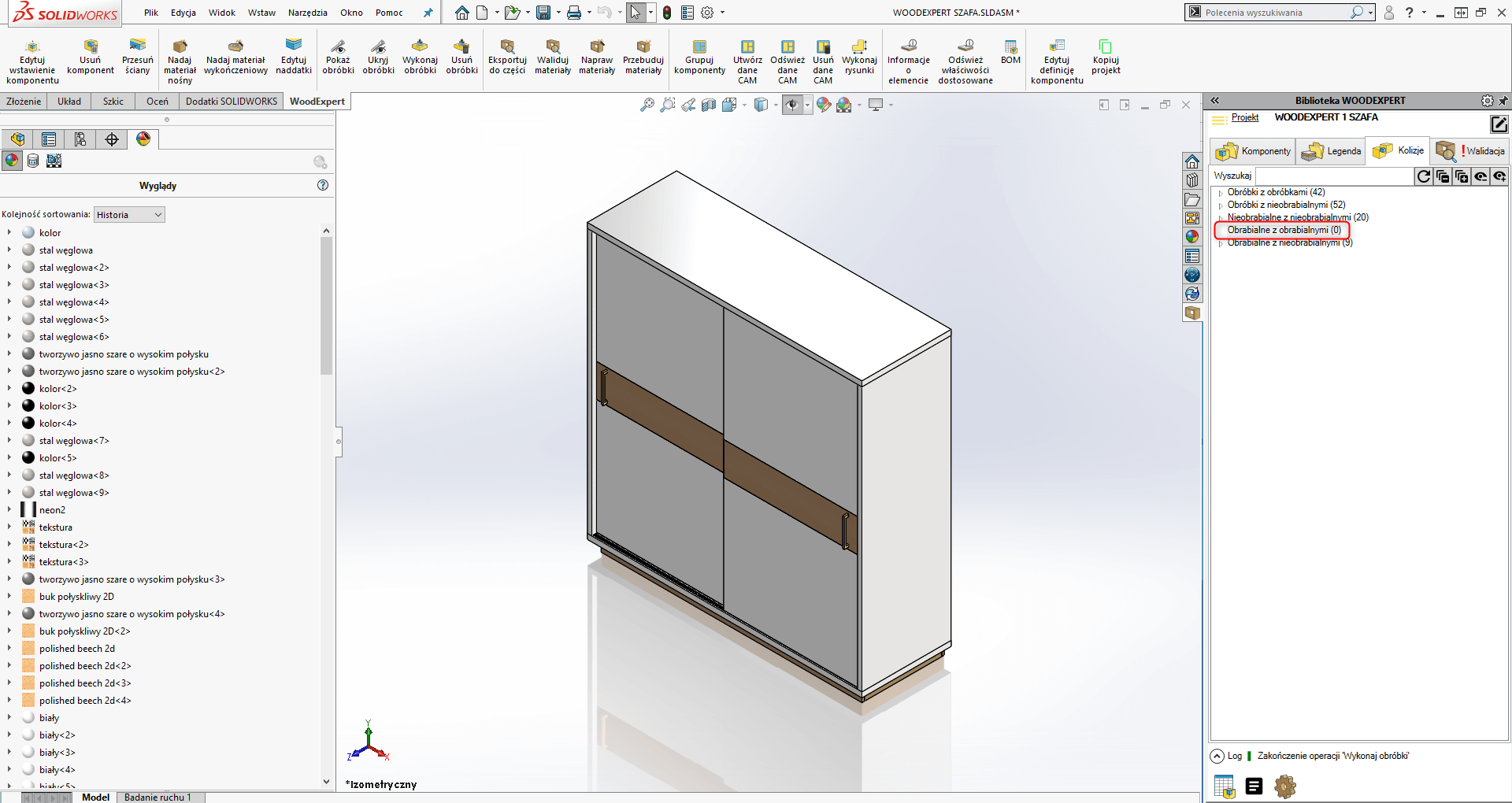

After performing the “Execute processing” operation, the following message disappears:

As you can see, before processing the program identifies the back as an element entering the body, and after carrying out the “Perform processing” operation this collision is removed. How the processing collision detection function in WOODEXPERT is used in practice?

Marcin Jórasz, WOODEXPERT specialist

Marcin Jórasz, WOODEXPERT specialist

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…