Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

Grouping components

Being WOODEXPERT developers, we decided to make furniture design not only less time-consuming, but also rewarding for the user. That is why we provided the software with a series of functions both improving the design process and ensuring great comfort of use. One of these functions is “Grouping components”.

With the component grouping function you can group the selected components and subsequently divide them by a specific milling head / saw thickness — as a result you obtain an additional template which, after cutting, allows for getting components with almost continuous natural wood grain structure. A detailed description of proper component grouping method is provided below.

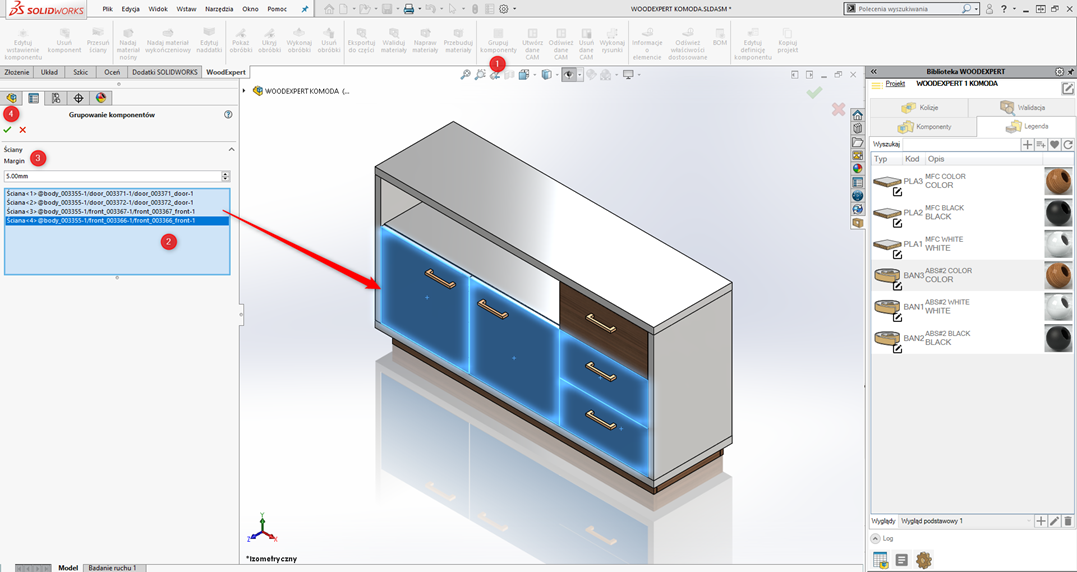

1. First, select the “Group components” operation from the WOODEXPERT Command Manager.

2. Then, select the components to be grouped by the software.

3. The next step is to enter a gap for cutting/milling tool:

4. Upon accepting the selection, the software automatically groups components and offsets them by the specified “margin”.

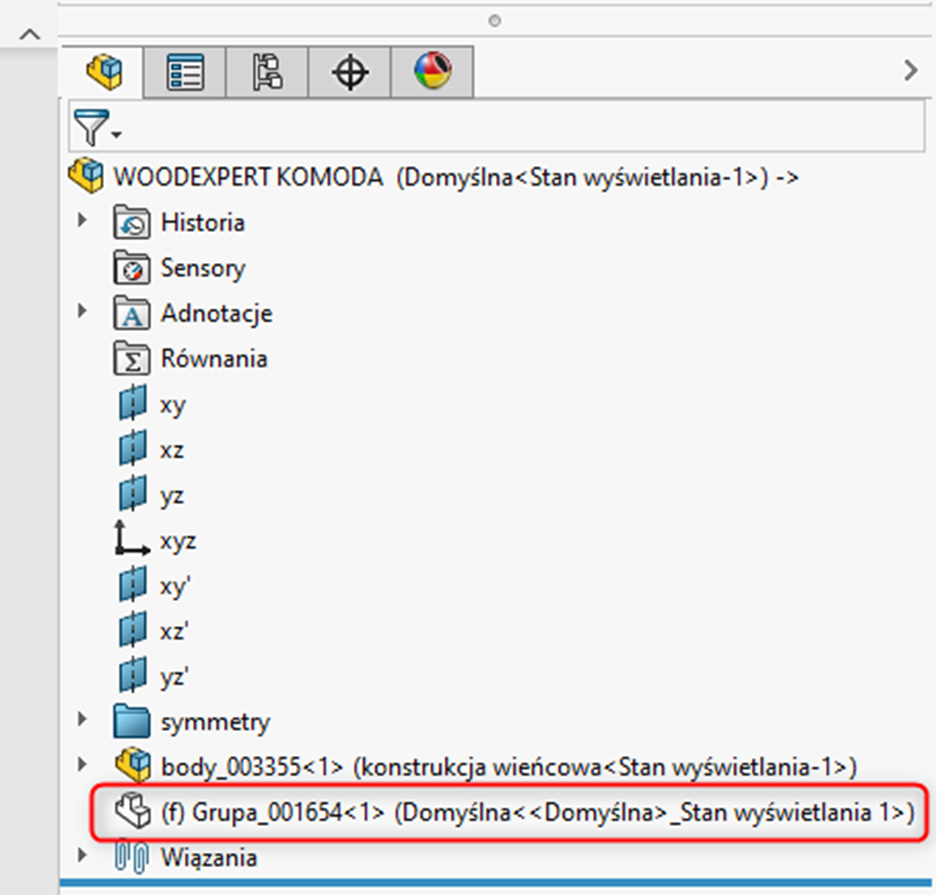

5. A new item is created in the FeatureManager operation tree:

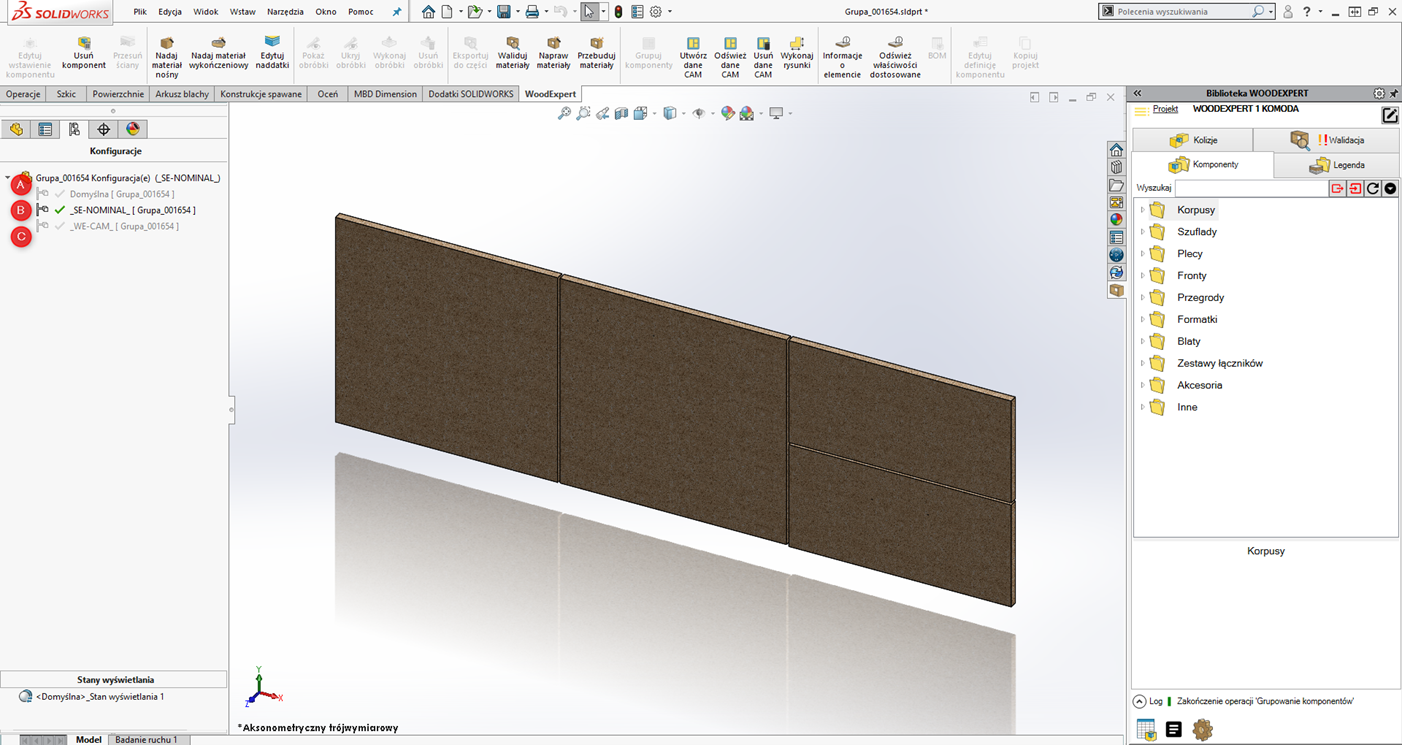

6. Such a component can have 3 configurations:

- default configuration, that is a template without allowances from which our components can be cut out;

- SE_NOMINAL configuration, that is all templates offset by 5 mm; based on their outline, the default configuration is created;

- WE-CAM configuration, that is a configuration created by the “Create CAM data” command by the user, containing a default template with process allowances suitable for a given material.

With one click, the user gets a part that is ready to be sent to the CAM program. In addition, the “group” is presented in the BOM, which takes it into account when counting project materials. Take a look at the tutorial showing how to work with the component grouping function in WOODEXPERT.

Author: Marcin Jórasz, WOODEXPERT specialist

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…