Since the beginning of our cooperation in 2005, the company has repeatedly confirmed its knowledge and professionalism in the solutions offered.

Ryszard Bedynek

Head of IT Department

Search in blog:

Unlocking New Possibilities: composite elements in furniture design software

The “Create Composite” function is one of the many features introduced for use in the latest version of WOODEXPERT 2023. The main idea behind its creation was to think about a specific type of end-user, namely hotel furniture manufacturing companies. This doesn’t mean that its use will be limited only to this industry, as it can also be useful for the production of domestic furnitures. In this article the principle of operation will be presented, and the purpose of this feature will be explained.

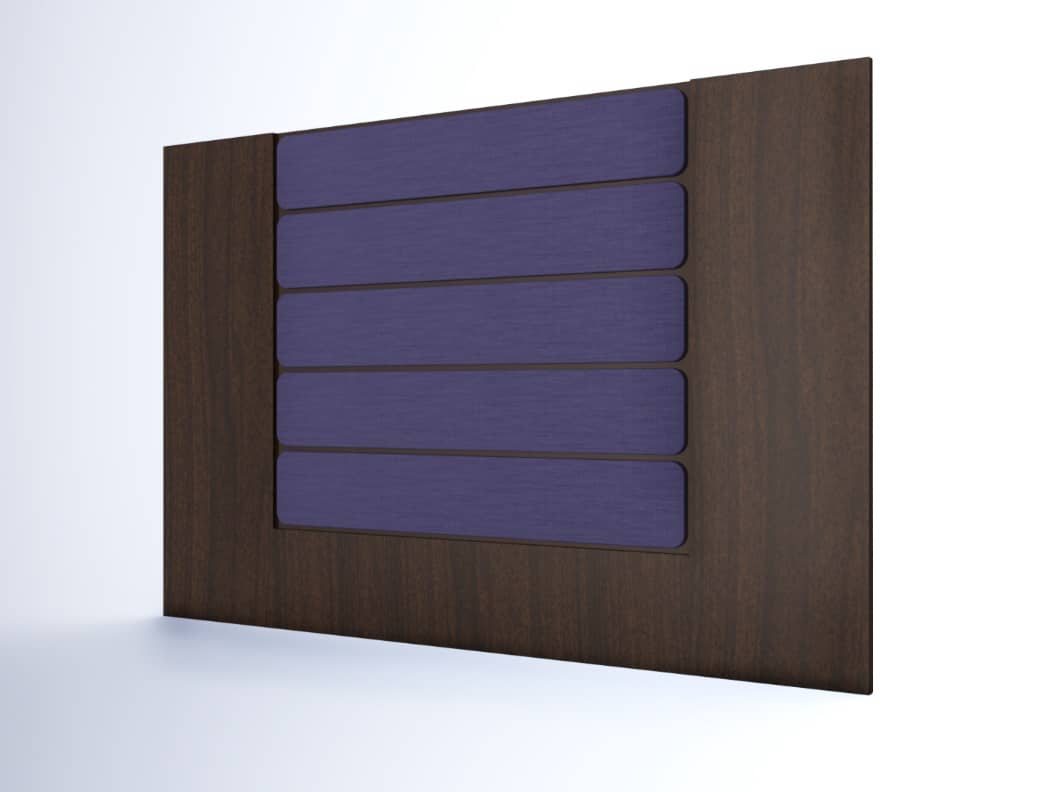

The “Create composite” function will apply to all furniture created on a composite basis, i.e., consisting of multiple panels faced with a single edgeband / cover. An example of such a multi-layered board is shown below:

A typical technological process for producing such a thickened panel / top would be as follows:

- Cutting out the formats on a panel saw / format saw together with the appropriate allowances

- Gluing / stitching of the formats

- Formatting process:- on the width / height dimensions to get a uniform edge for edgebands

– grinding the surface for the veneer (only under the condition that the panel will be veneered with laminate and our production plant has a grinder) to maintain the proper thickness of the panel - Bonding of laminate / edgebands

- Machining of any holes / pockets on the machining center.

Thanks to the “Create composite” function, WOODEXPERT is able to support the user at every stage of this process, starting with preparing the list of formats for cutting, passing on the information about wrapping, sanding, formatting and ending with CAM processing. Let’s now move on to a step-by-step presentation of the principle:

1. Modeling a raw panel

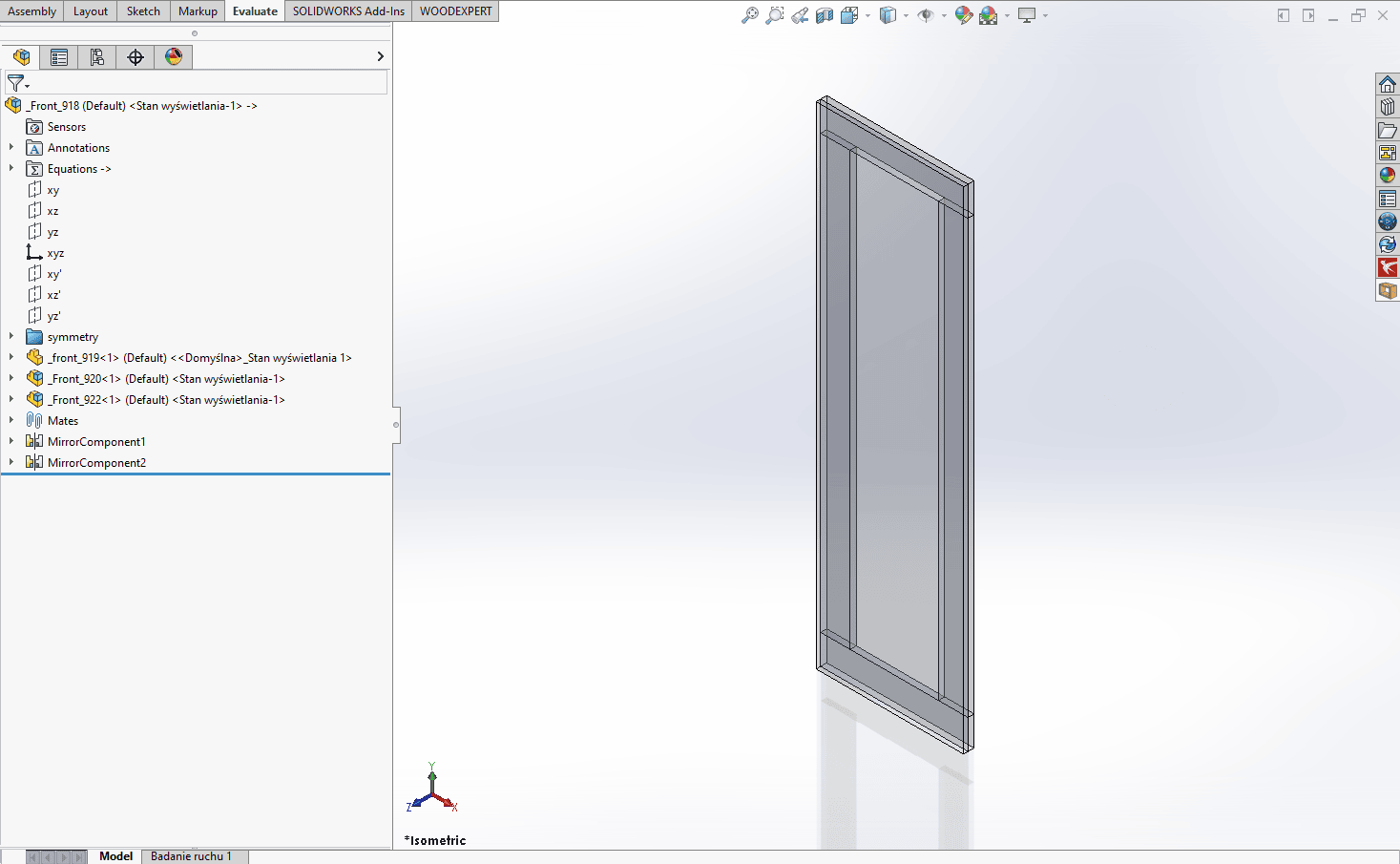

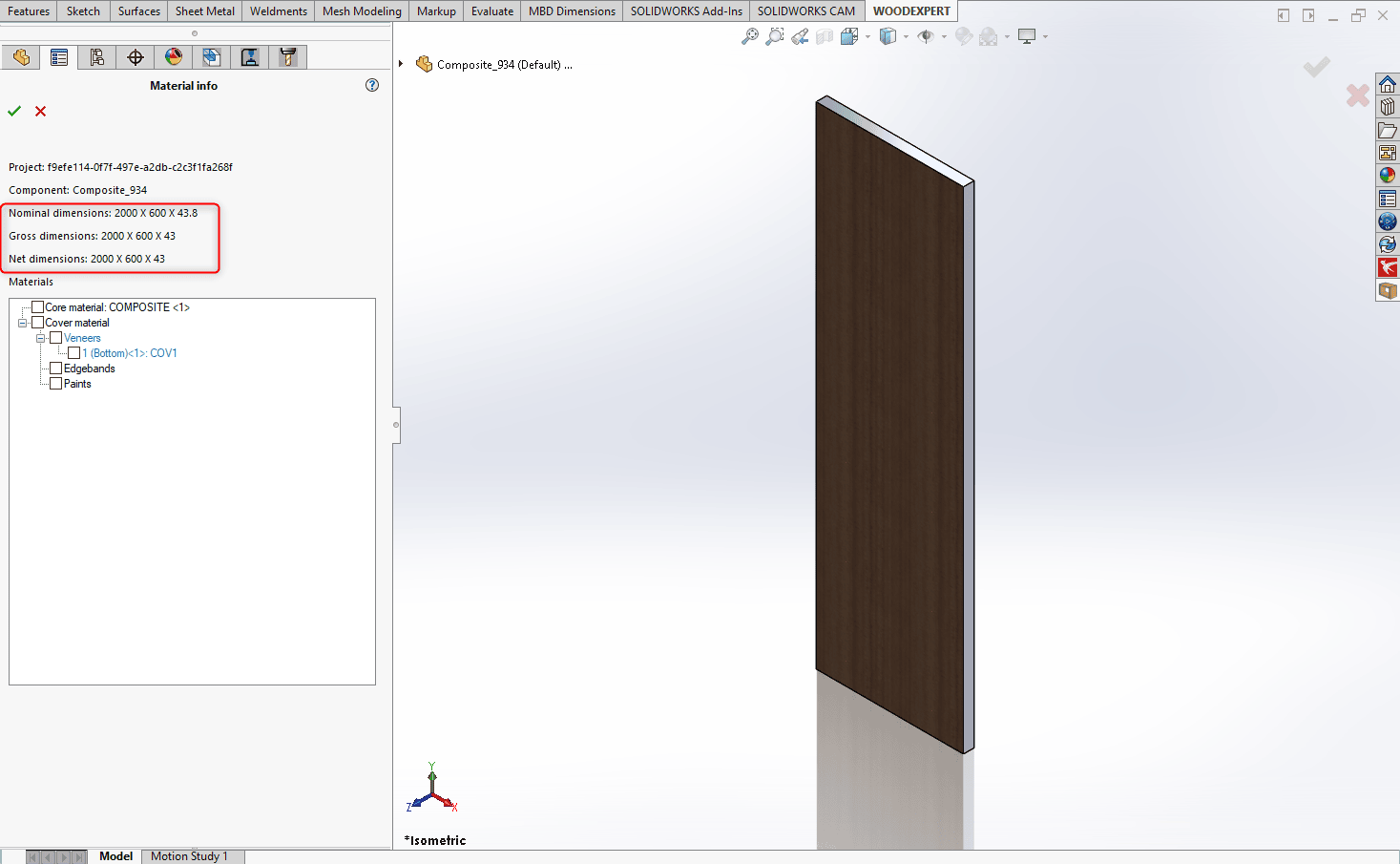

Modeling a raw panel – the first step is to create a raw (unfinished) panel of any geometry and shape without considering finishing materials. In this case, we will use the example of a wall panel for KING beds:

2. Assigning core materials

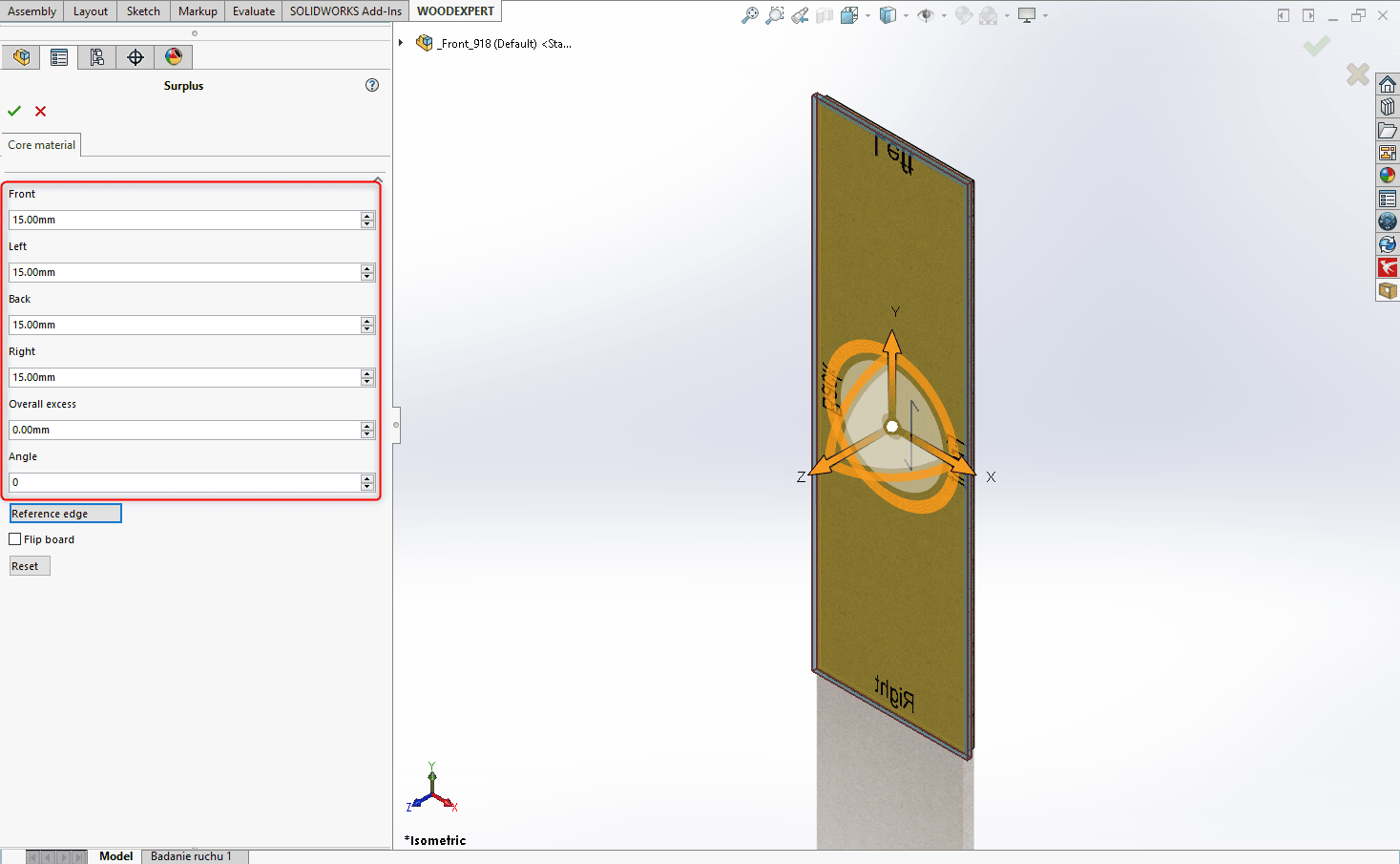

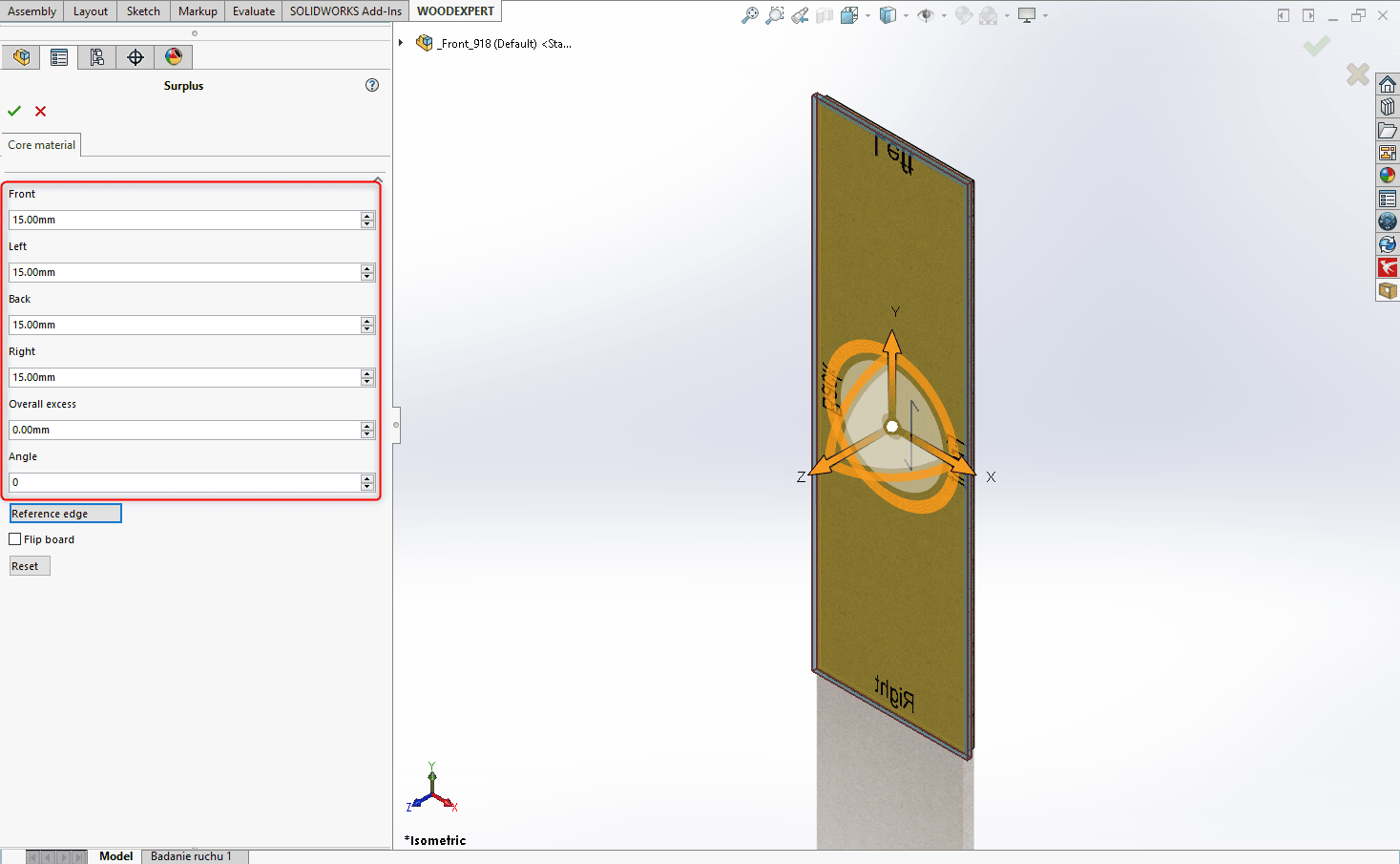

Assigning core materials – based on the information contained in the materials, the correct dimensions of the panel will be determined. With the assignment of core materials, we get the opportunity to assign initial allowances, which will be necessary for the proper formatting of the panel.

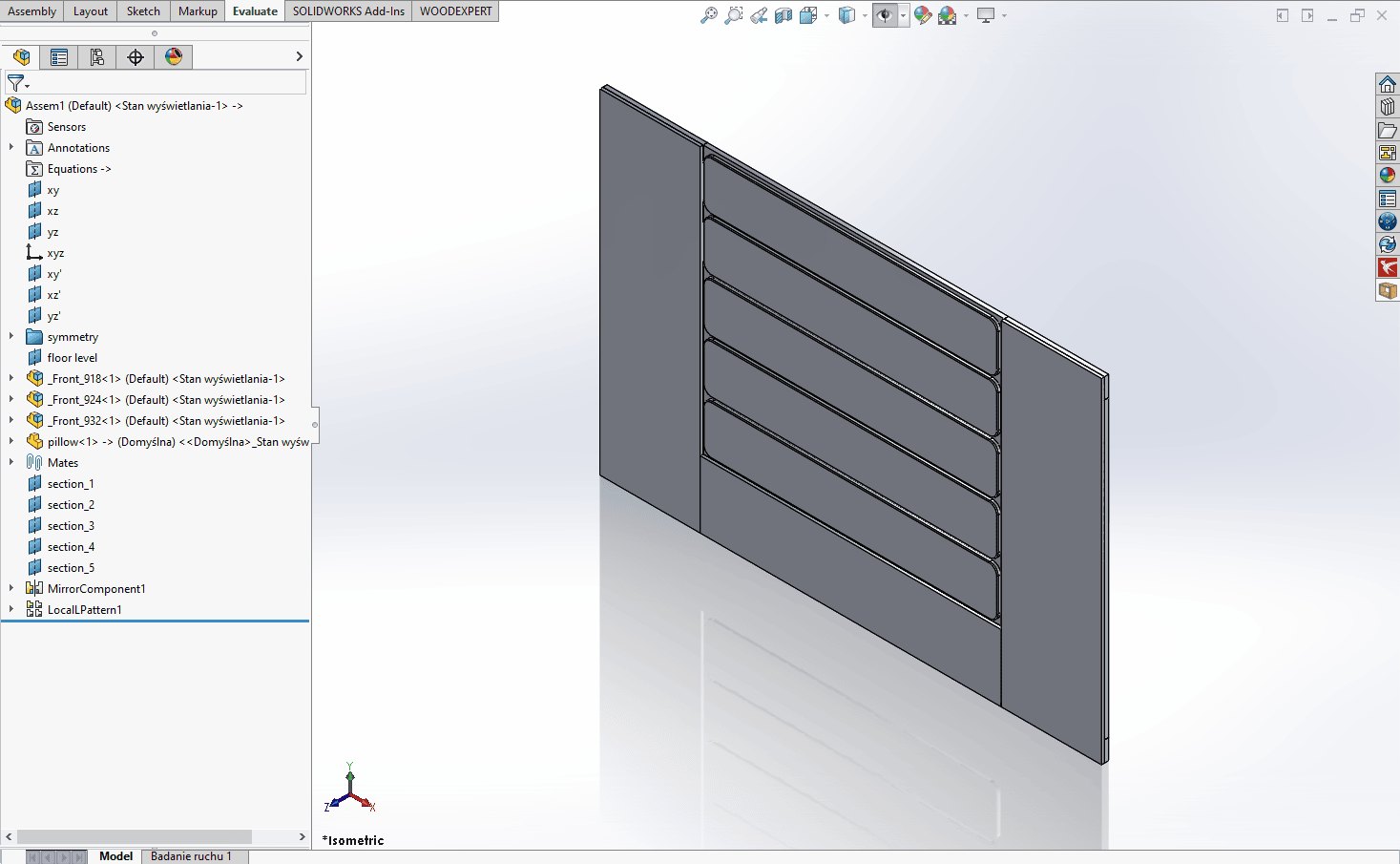

3. Creation of composites

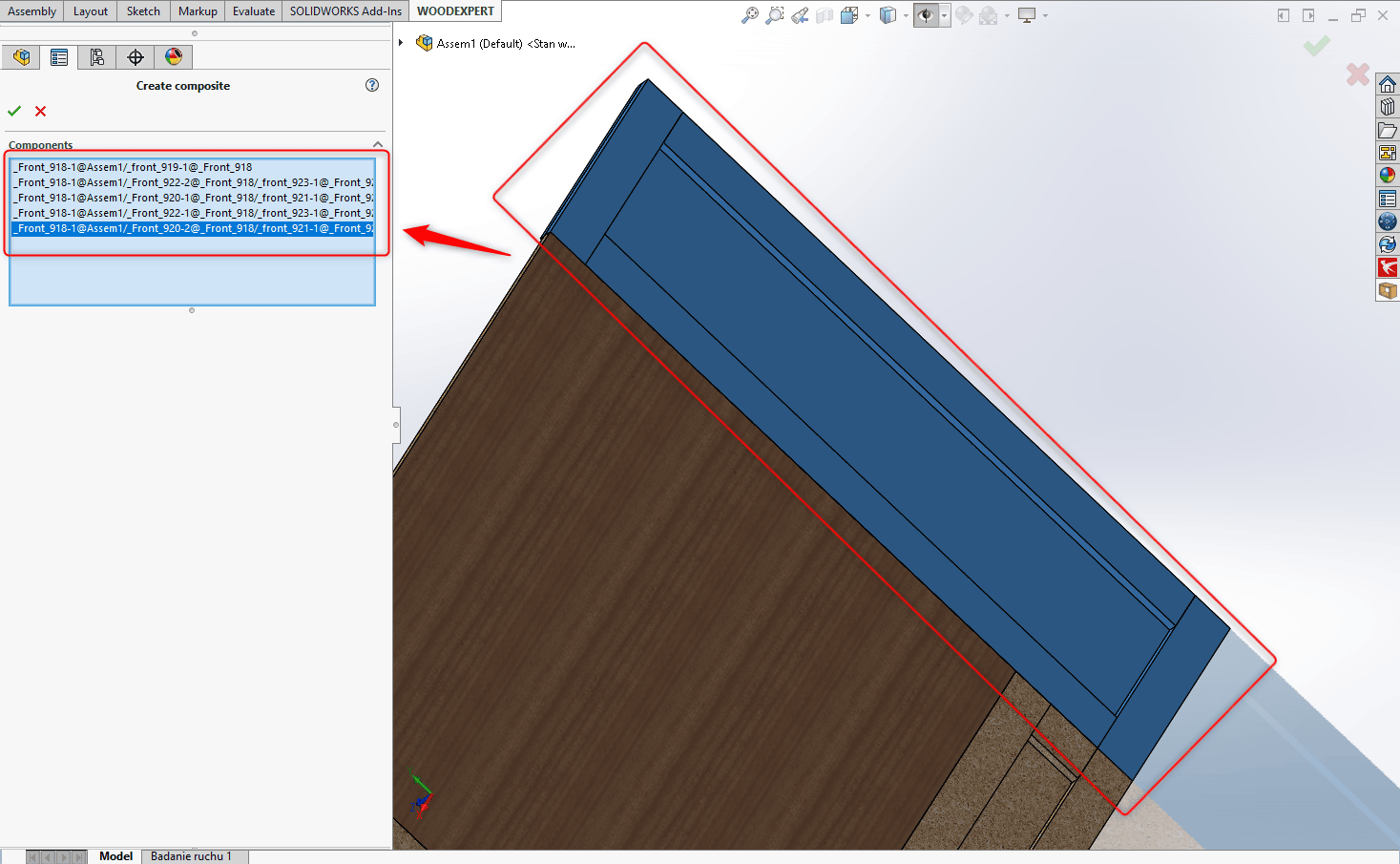

Creation of composites – means grouping the relevant formats into a “unified” panel, for this purpose we use the function “Create composite”.

When the program executes a command, an automatically generated “composite” appears in the form of a uniform solid (which also means uniform narrow edges and wide planes):

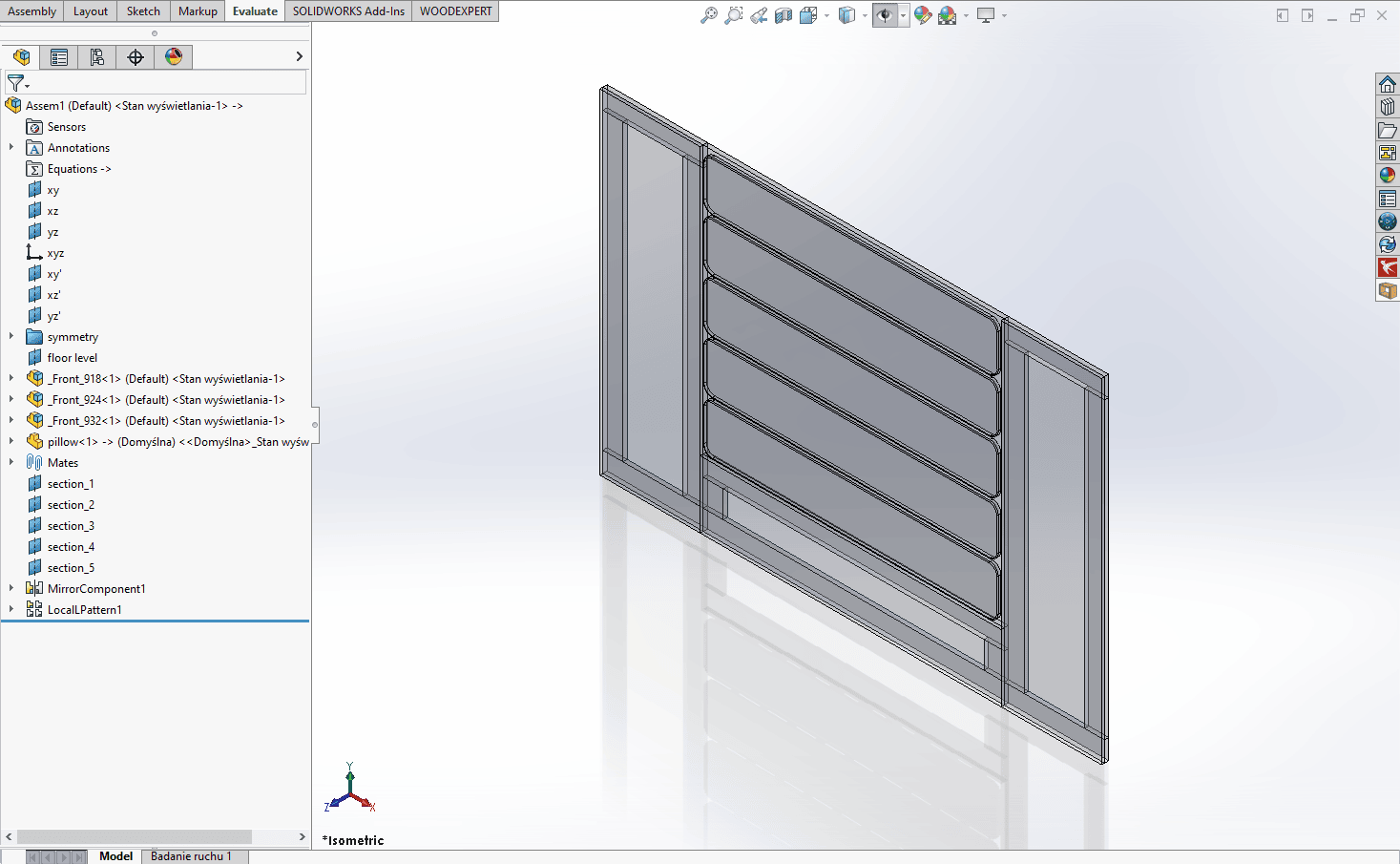

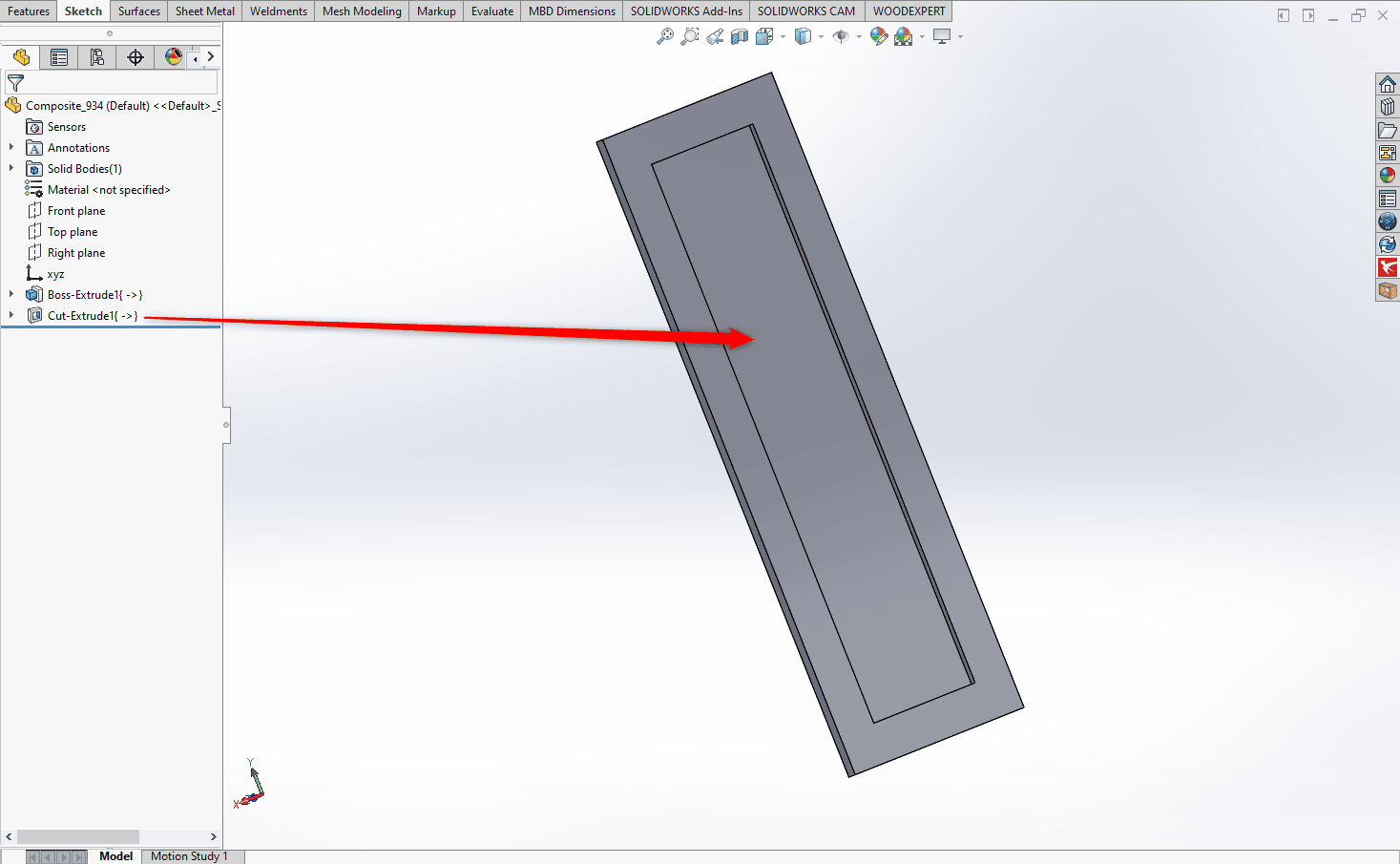

4. Adjust the geometry / shape of the panel

Adjust the geometry / shape of the panel – the solid of the composite is created automatically based on the bounding box created from the selected elements. At this stage, the user should adjust the shape of the generated composite, using SOLIDWORKS tools, such as Extruded Cuts.

5. Assigning finishing materials

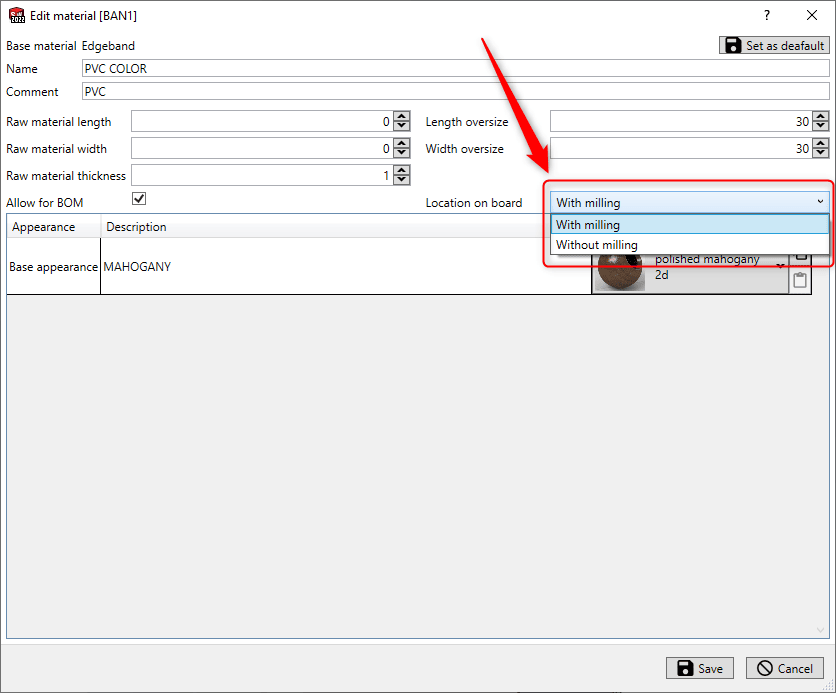

Assigning finishing materials – once the panel has the desired shape, you can move on to assigning finishing materials. For this purpose, the function uses the following information:

- Location of edgeband on the panel:

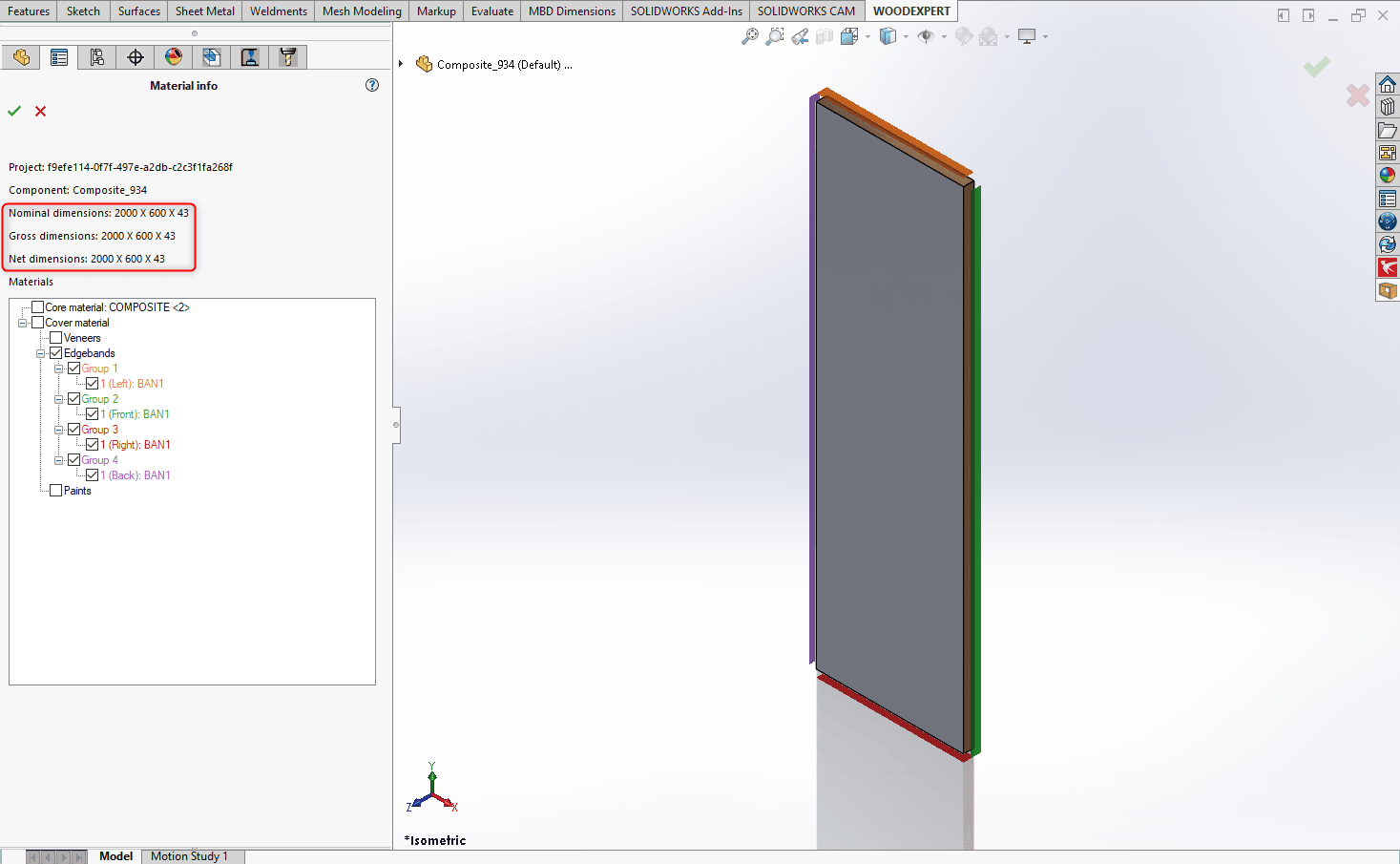

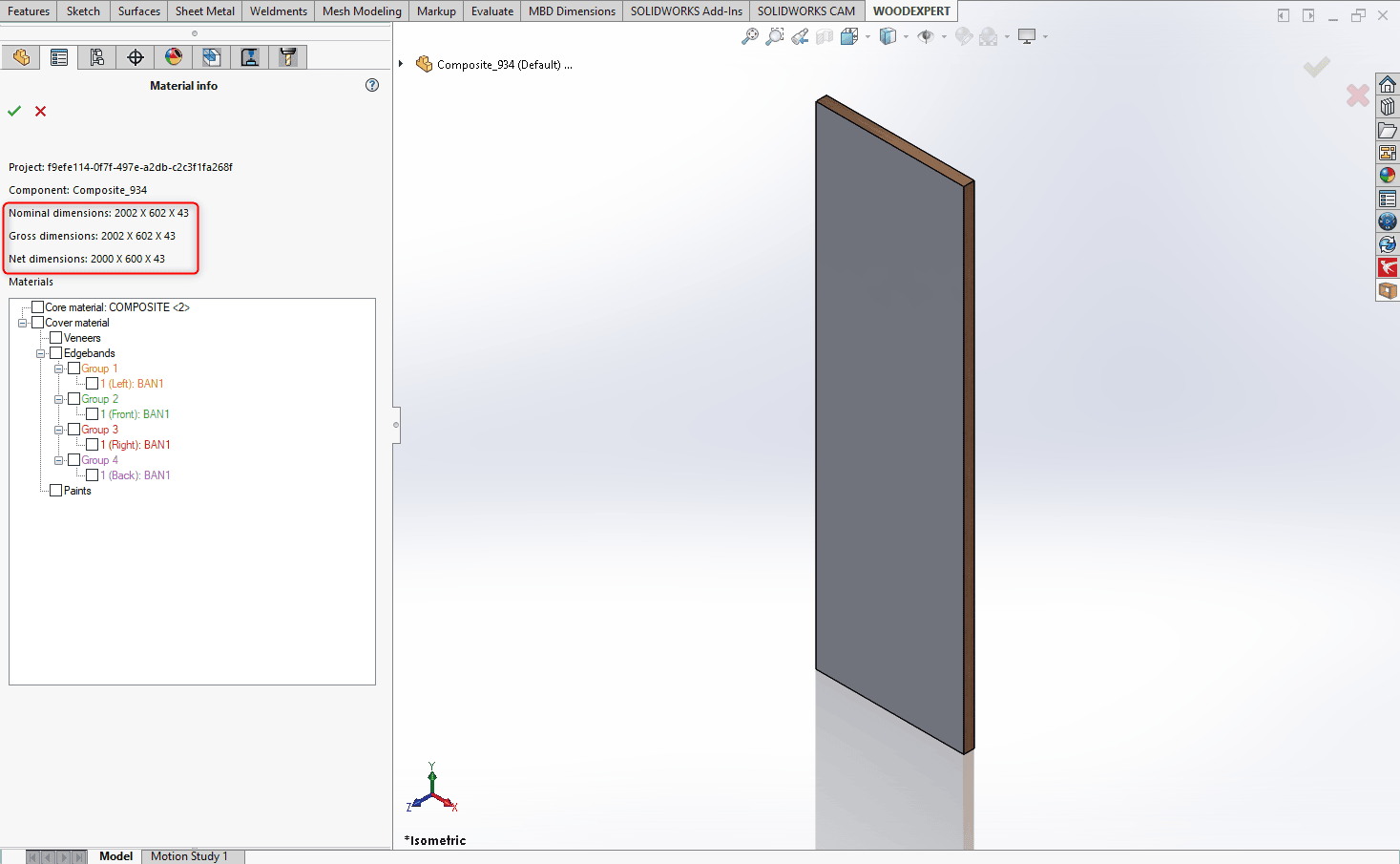

- With milling – the dimension of the length and width of the element remains unchanged when the edgeband is assigned:

- Without milling – the composite is enlarged in length and width by the thickness of the assigned edgeband:

- Location of wide cover on the panel:

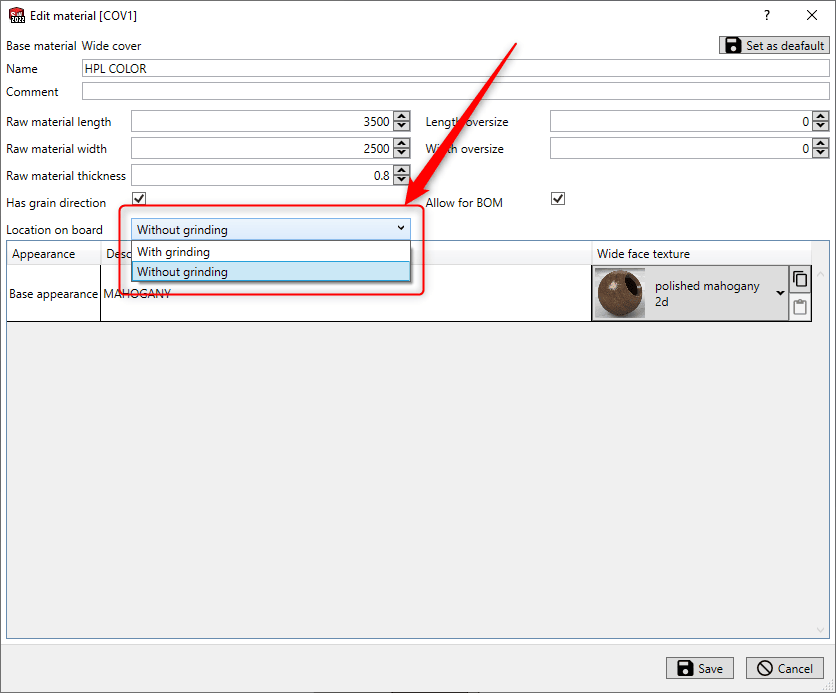

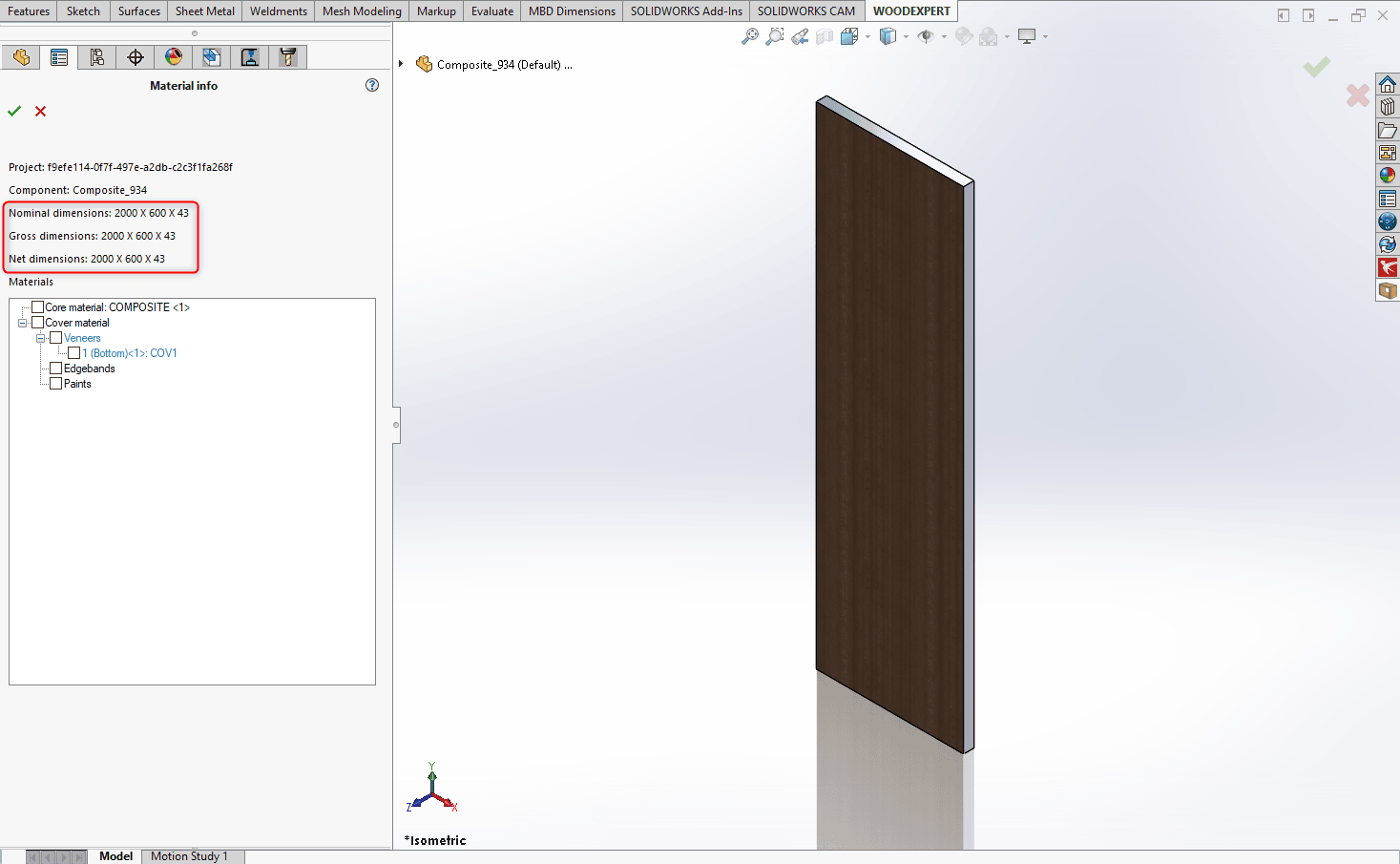

- With grinding – the thickness dimension of the piece remains the same when the wide cover is assigned:

- Without grinding – the composite is increased in thickness by the thickness of the assigned wide cover:

6. Model validation and production data generation

Model validation and production data generation – validate the model and generate data such as:

- Nesting

- NC programs

- 2D drawings

- BOMs

In summary, the “Create composite” function opens up new possibilities for users to model products such as panels, wall panels, and thickened countertops, where the structure is based on put-together panels – often including multi-materials. Among its key benefits are:

- Accelerated modeling

- Automatic creation of production data

- Material savings

- Reduction of costs associated with production

- Ability to implement a new type of furniture into the portfolio

- Flexibility to different machine park configurations.

If you are curious about other capabilities of our software, follow our blog and social media.

Recent posts

In today’s market, to stay afloat, one has to keep up to date with newest technologies. There’s nothing wrong with being an artisan with a plane in one hand and…

You can also generate a bill of materials for the entire project with a single click. Our extended and improved BOM module has many possibilities for data acquisition: reports, catalogs,…

The drawing generator is something our customers love. Drawings can also be automatically generated working from a developer's projection. Don't miss to see how to create in seconds...a finished PDF…

The third tutorial in this series shows how to give supporting and finishing materials to a model: in an unconventional way. The method of building a material legend and surface…

In this tutorial, we present a quick and optimal way to model in WOODEXPERT based on a 2D projection. It involves inserting parametric furniture from a ready-made library based on…